Warp stopping bar middle supporting frame structure

A bracket structure and warp slat technology, applied in textiles, textiles, papermaking, looms, etc., can solve the problems of limited space, the pull-out of the drop-off slats, and the slow removal of the drop-off slats 2, etc., to achieve convenient manufacturing. , the effect of eliminating friction and shortening standby time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

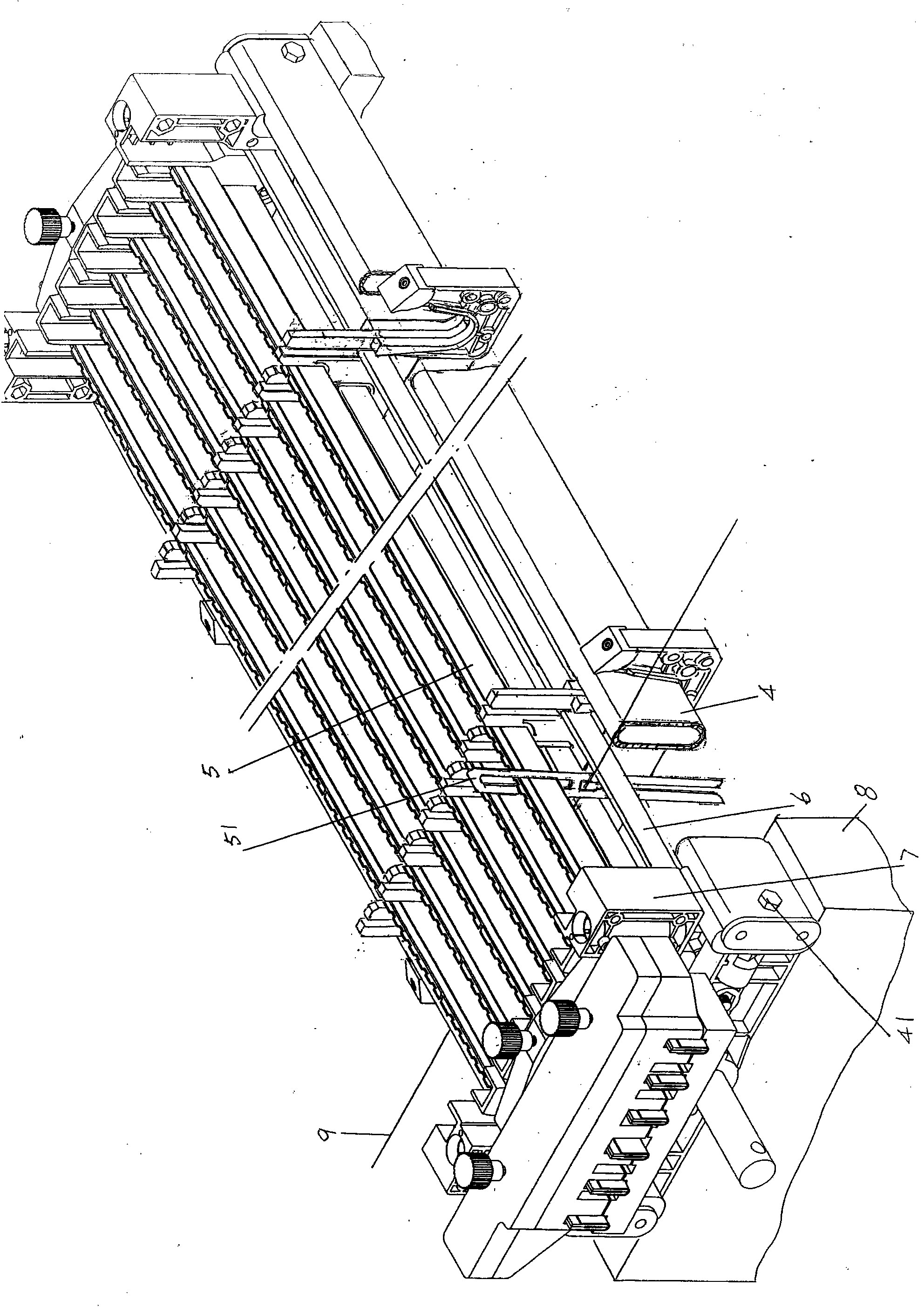

[0026] See figure 1 , provides a warp creel fixing plate 1 that preferably adopts plastics and is obtained through mould-making, respectively integrally forms a warp creel fixing plate seat 11 at the left end and the right end of this warp creel fixing plate 1, on the warp creel fixing plate seat 11 The upward position (i.e. the upward side) constitutes a U-shaped warp frame 4 ( figure 2 Show) matching warp creel matching cavity 111. because figure 2 The cross-sectional shape of the shown warp creel 4 is generally oval, so the warp creel matching chamber 111 is designed as U-shaped, but if the cross-sectional shape of the warp creel 4 is changed for the purpose of avoiding the design of the present invention, And if the shape of the warp creel matching chamber 111 is also adapted, it should be regarded as an equivalent replacement and still belongs to the scope of the disclosed technical content of the present invention. Depend on figure 1 As shown, on the top of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com