Desulfurization method and device for liquefied petroleum gas

A technology of liquefied petroleum gas and desulfurization equipment, which is applied in the petroleum industry, gas fuel, fuel, etc., and can solve problems such as potential safety hazards, difficulty in removing sulfur content, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

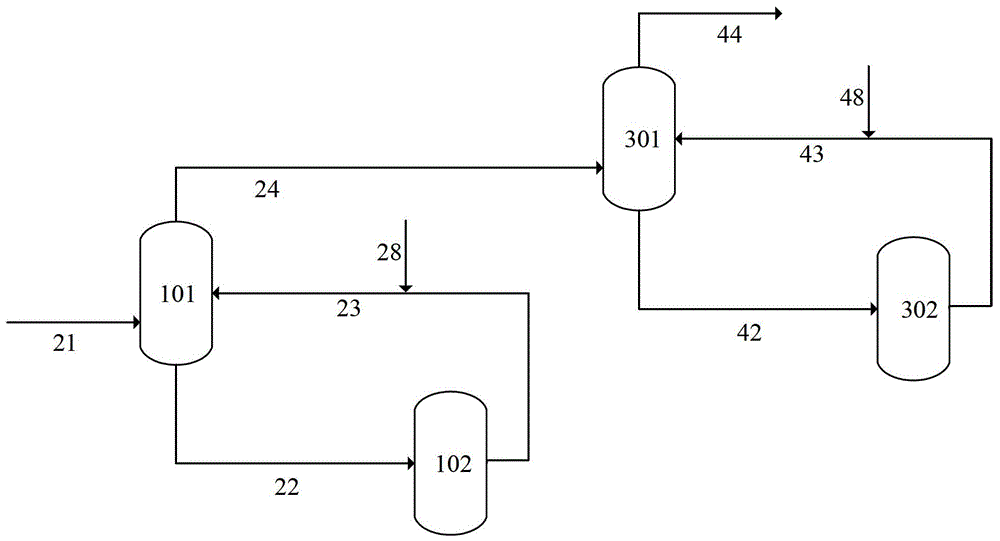

[0061] The following combination figure 1 The desulfurization method and device of the present invention will be described.

[0062] The catalytic liquefied petroleum gas to be desulfurized is the stable liquefied petroleum gas obtained from the MIP process of a refinery affiliated to Sinopec Corporation.

[0063]The alcohol amine desulfurizer SSH-3 of Changzhou Taihu Chemical Co., Ltd. was mixed with distilled water to prepare a 30% alcohol amine aqueous solution, and a 50% dimethyl ketoxime solution was added to the alcohol amine aqueous solution. The amount added is 10 mg / kg of the alcohol amine aqueous solution.

[0064] The mixture of alcohol amine aqueous solution and dimethyl ketoxime solution enters the alcohol amine desulfurization unit 101 through the input pipeline 28 to carry out the desulfurization test with catalytic liquefied petroleum gas. The volume ratio of liquefied petroleum gas is 1:2.5, and the liquid hourly volume space velocity of catalytic liquefied ...

Embodiment 2

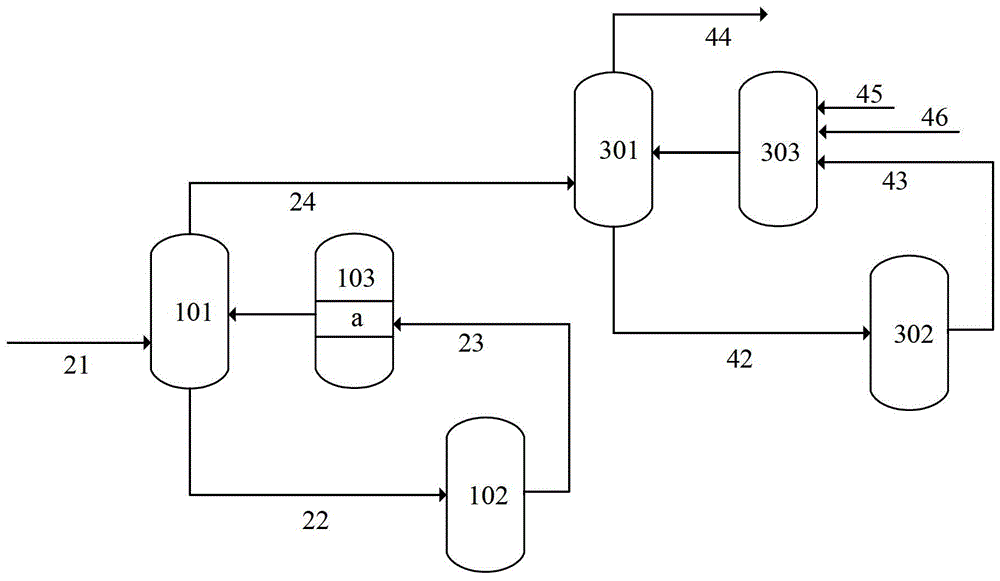

[0074] The following combination image 3 The desulfurization method and device of the present invention will be described.

[0075] The coking liquefied petroleum gas to be desulfurized is obtained from the stable liquefied petroleum gas of the delayed coking process of a refinery affiliated to Sinopec Corporation.

[0076] The alcohol amine composite desulfurizer (mainly composed of N-methyldiethanolamine) of Jiangsu Innovation Chemical Co., Ltd. was mixed with distilled water to prepare an alcohol amine aqueous solution with a content of 28%.

[0077] A deoxidizer fixed bed a is set in the alcohol amine deoxygenation unit 103, and a hydroquinone resin is loaded in the deoxidizer fixed bed a, so that the above alcohol amine aqueous solution passes through the alcohol amine deoxygenation unit 103, and after passing through the alcohol amine aqueous solution, it is oxidized The content of sexual substances is less than 0.1mg / L.

[0078] The alcohol amine aqueous solution aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com