Alkaline desulfurization method and device for liquefied petroleum gas

A technology for liquefied petroleum gas and lye, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of high energy consumption of redistillation, hidden dangers, and difficulty in removing sulfur content, so as to improve desulfurization efficiency and reduce sulfur content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The following combination figure 1 To illustrate the lye desulfurization method and device of the present invention.

[0057] The liquefied petroleum gas to be treated is the stable liquefied petroleum gas obtained from the catalytic process of a refinery affiliated to Sinopec Co., Ltd. after treatment with alcohol amine.

[0058] The lye used is taken from regenerated lye from a refinery of Sinopec, in which the content of sodium hydroxide is 15%, and the content of cobalt sulfonated phthalocyanine is 150mg / kg.

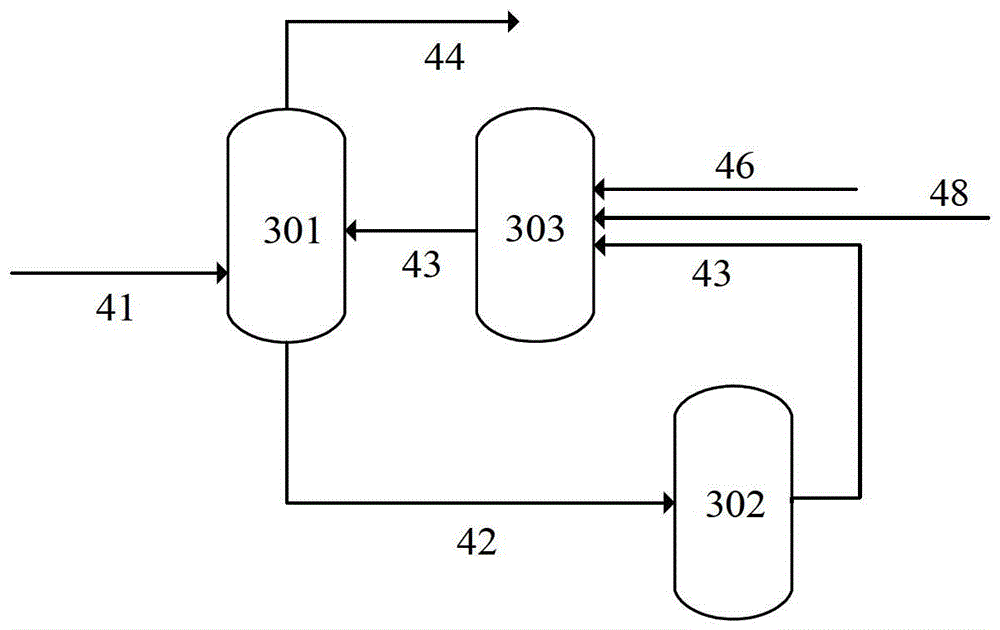

[0059] The lye is injected into the lye deoxygenation unit 303 from the lye input line 46, and the heptane containing 4200mg / kg vitamin E is injected into the lye deoxygenation unit 303 from the common input line 48 of the deoxidizer and hydrocarbon oil, and the volume ratio of the lye to the heptane is The ratio is 25:1. After the two are mixed for 1-5 minutes, they are allowed to stand for stratification. The separated lye enters the lye desulfurization uni...

Embodiment 2

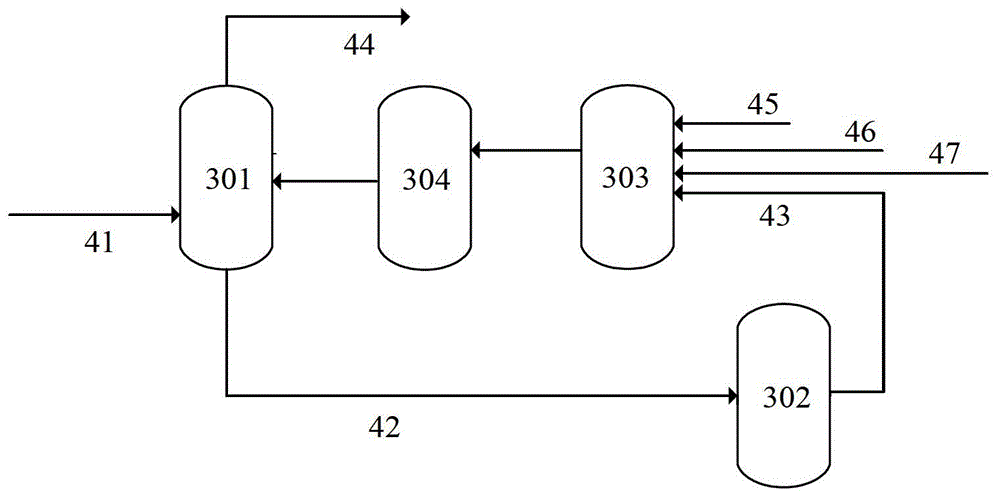

[0066] The following combination Figure 4 To illustrate the lye desulfurization method and device of the present invention.

[0067] The liquefied petroleum gas to be treated is the stable liquefied petroleum gas obtained after the delayed coking process of a refinery affiliated to Sinopec Co., Ltd. after treatment with alcohol amine.

[0068] The lye used is fresh lye, the content of sodium hydroxide is 15%, and the content of cobalt sulfonated phthalocyanine is 50mg / kg.

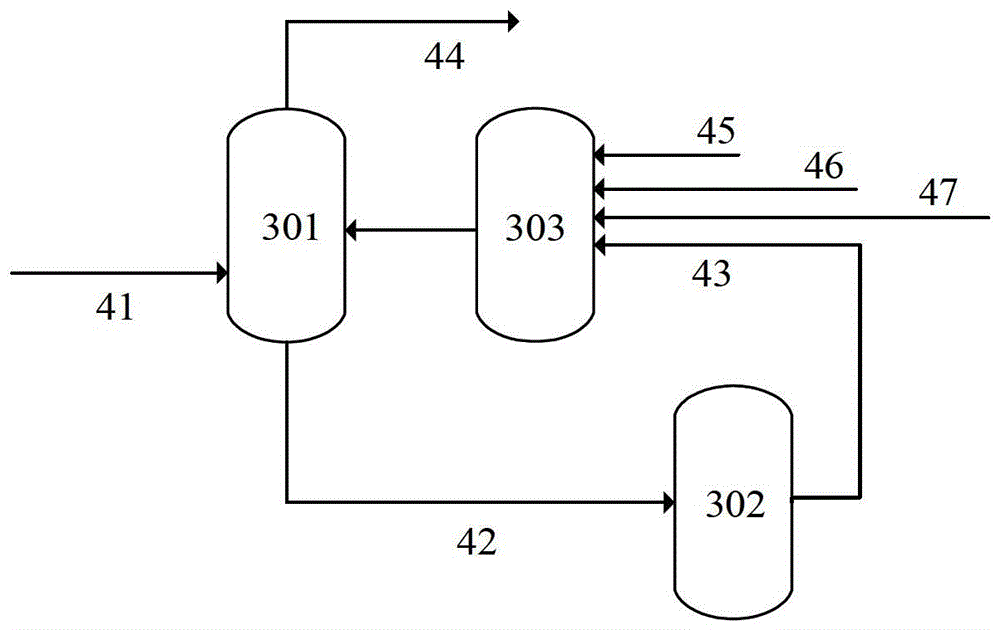

[0069] The lye is injected into the lye deoxidation unit 303 from the lye input pipeline 46, and the hexane containing 2100 mg / kg methyl mercaptan (deoxidizer) is injected into the lye deoxygenation unit 303 from the common input pipeline 48 of the deoxidizer and hydrocarbon oil, and the lye and The volume ratio of hexane is 25:1, the two are mixed and stirred, the temperature is 40°C, and the time is 2 minutes. The methyl mercaptan in hexane will react with the oxidizing substances in the lye to form Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com