Alcohol amine desulfurization method and device for liquefied petroleum gas

A technology of liquefied petroleum gas and desulfurization equipment, applied in chemical instruments and methods, petroleum industry, separation methods, etc., can solve the problems of high energy consumption for re-distillation, difficulty in removing sulfur content, hidden safety hazards, etc., and achieve the goal of improving desulfurization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

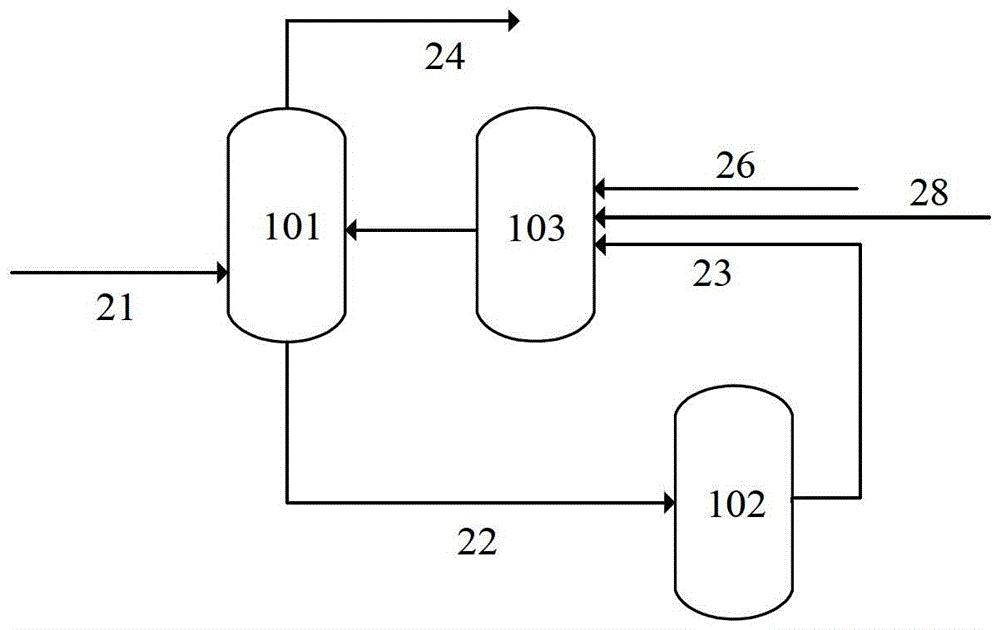

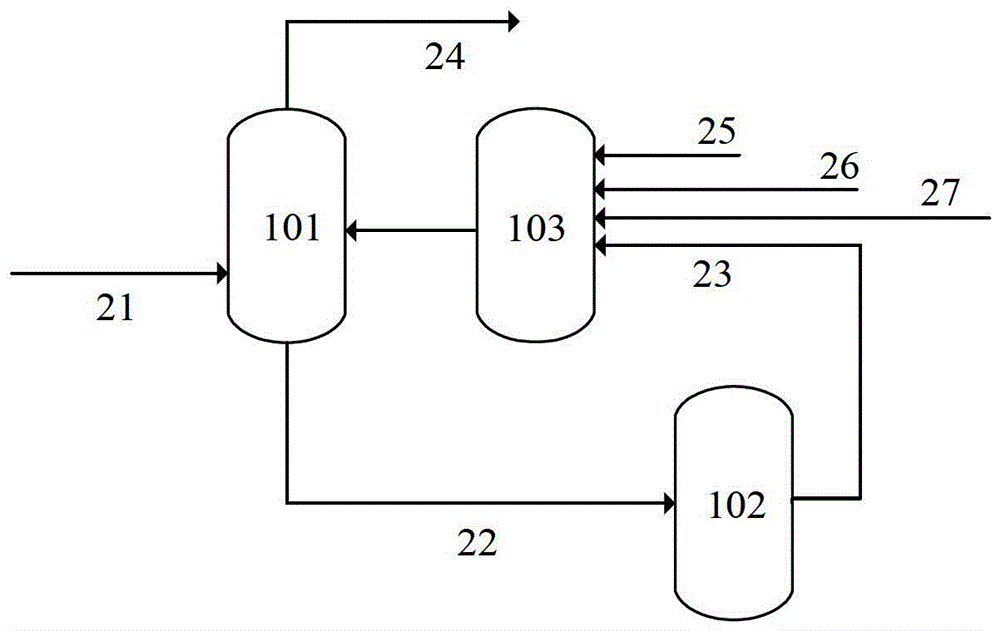

[0052] The following combination figure 1 To illustrate the alcohol amine desulfurization method and device of the present invention.

[0053] Mix alcohol amine desulfurizer SSH-3 with distilled water to prepare a 30% alcohol amine aqueous solution. The catalytic liquefied petroleum gas to be treated is the stable liquefied petroleum gas obtained from the MIP process of a refinery affiliated to Sinopec Corporation.

[0054] Input the above-mentioned alcohol amine aqueous solution in the alcohol amine aqueous solution input pipeline 26, input the hexane that has added 2100mg / kg methyl mercaptan (deoxidizer) in the common input pipeline 28 of deoxidizer and hydrocarbon oil, the two are by volume ratio 25:1 injection into the alcohol amine deoxidation unit 103 for mixing and stirring, the temperature is 40°C, and the time is 2 minutes. The methyl mercaptan in hexane will react with the oxidizing substances in the alcohol amine aqueous solution to form disulfide existing in the o...

Embodiment 2

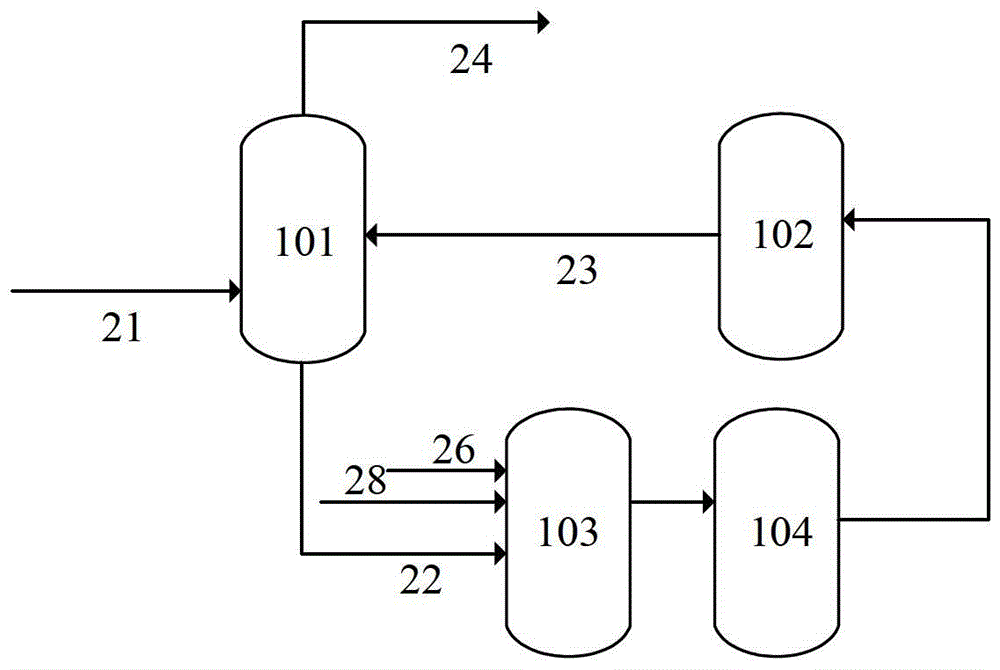

[0061] The following combination image 3 To illustrate the alcohol amine desulfurization method and device of the present invention.

[0062] The alcohol amine composite desulfurizer (mainly composed of N-methyldiethanolamine) of Jiangsu Innovation Chemical Co., Ltd. was mixed with distilled water to prepare an alcohol amine aqueous solution with a content of 28%. The coking liquefied petroleum gas to be processed is the stable liquefied gas obtained from the delayed coking process of a refinery affiliated to Sinopec Corporation.

[0063] The above-mentioned alcohol amine aqueous solution is input in the input pipeline 26 of the alcohol amine aqueous solution, and the hexane added with 5000 mg / kg vitamin E is input in the common input pipeline 28 of the deoxidizer and hydrocarbon oil, and the two are injected into the alcohol at a volume ratio of 30:1. The amine deoxygenation unit 103 is mixed and stirred, the temperature is 40°C, and the time is 2 minutes, and then input to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com