Device and method for transferring CVD grown graphene

A transfer method and transfer device technology, applied in the field of thin film materials, can solve problems such as cracking, sample performance impact, residue and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

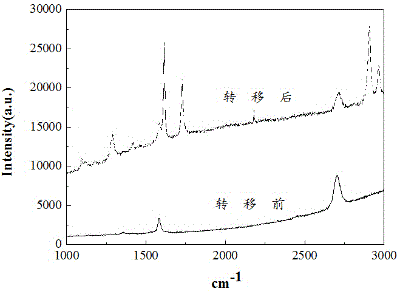

Embodiment 1

[0026] 1) Graphene was grown on the Cu substrate by chemical vapor deposition, and the graphene grown on the back of the substrate was removed by oxygen plasma; 2) PET was fixed at the same end as the single-sided graphene / Cu sample obtained in step 1) On the wall of the container with a circular hole with a diameter of 10 mm hollowed out at the bottom, the PET is parallel to the liquid surface of the ferric chloride solution, and the single-sided graphene / Cu sample is inserted below the liquid surface at 30 degrees; 3) Step 2) Immersed in the liquid The Cu part under the surface is etched first, adjust the position of the liquid level of the hollow container, so that the graphene and PET are in contact with each other, that is, the transfer is completed first; 4) Use a syringe to adjust the position of the liquid level of the ferric chloride solution, and repeat step 3) Etching and transfer operations, so that the single-sided graphene sample is gradually etched from the free ...

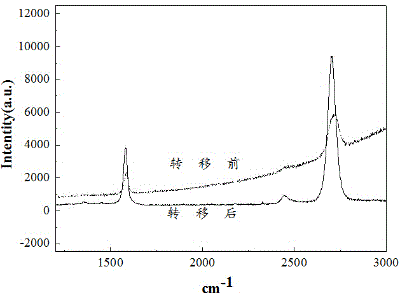

Embodiment 2

[0028] 1) Graphene was grown on the Cu substrate by chemical vapor deposition, and the graphene grown on the back of the substrate was removed by oxygen plasma cleaning; 2) Si was placed at the same end as the single-sided graphene / Cu sample obtained in step 1) Fixed on the wall of a hexagonal container with a hollow bottom diameter of 10 mm, where Si is parallel to the liquid surface of the ammonium persulfate solution, and the single-sided graphene / Cu sample is inserted below the liquid surface at 20 degrees; 3) Step 2) Immersed in The Cu part under the liquid surface is first etched, adjust the liquid surface position of the hollow container, make the graphene and Si contact and bond, that is, the transfer is completed first; 4) Adjust the liquid surface position of the ammonium persulfate solution with a syringe, repeat step 3) Etching and transfer operations, so that the single-sided graphene sample is gradually etched from the free end to the fixed end until all the etchi...

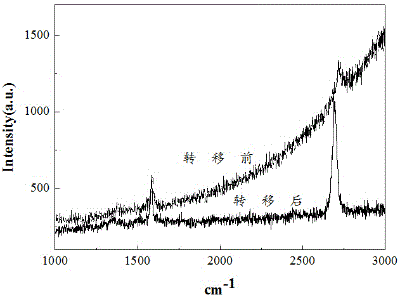

example 3

[0030] 1) Graphene was grown on the Cu substrate by chemical vapor deposition, and the graphene grown on the back of the substrate was removed by oxygen plasma cleaning; 2) Al 2 o 3 The same end of the single-sided graphene / Cu sample obtained in step 1) is fixed on the wall of a container with a hollow bottom and a side length of 10mm square, where Al 2 o 3 Parallel to the liquid surface of the potassium persulfate solution, the single-sided graphene / Cu sample is inserted below the liquid surface at 10 degrees; 3) The Cu part immersed in the liquid surface in step 2) is etched first, and the liquid surface position of the hollow container is adjusted, Make graphene and Al 2 o 3 Contact and fit, that is, the transfer is completed first; 4) Use a syringe to adjust the liquid level of the potassium persulfate solution, repeat the etching and transfer in step 3), so that the single-sided graphene sample is gradually etched from the free end to the fixed end until All etching i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com