Base for printer, printer with base and data printer for airplane

A technology of printer frame and axle seat, which is applied in the direction of printing device and printing, and can solve the problems of reduced reliability, complicated design of printer circuit and structure, inconvenience of printer inspection and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

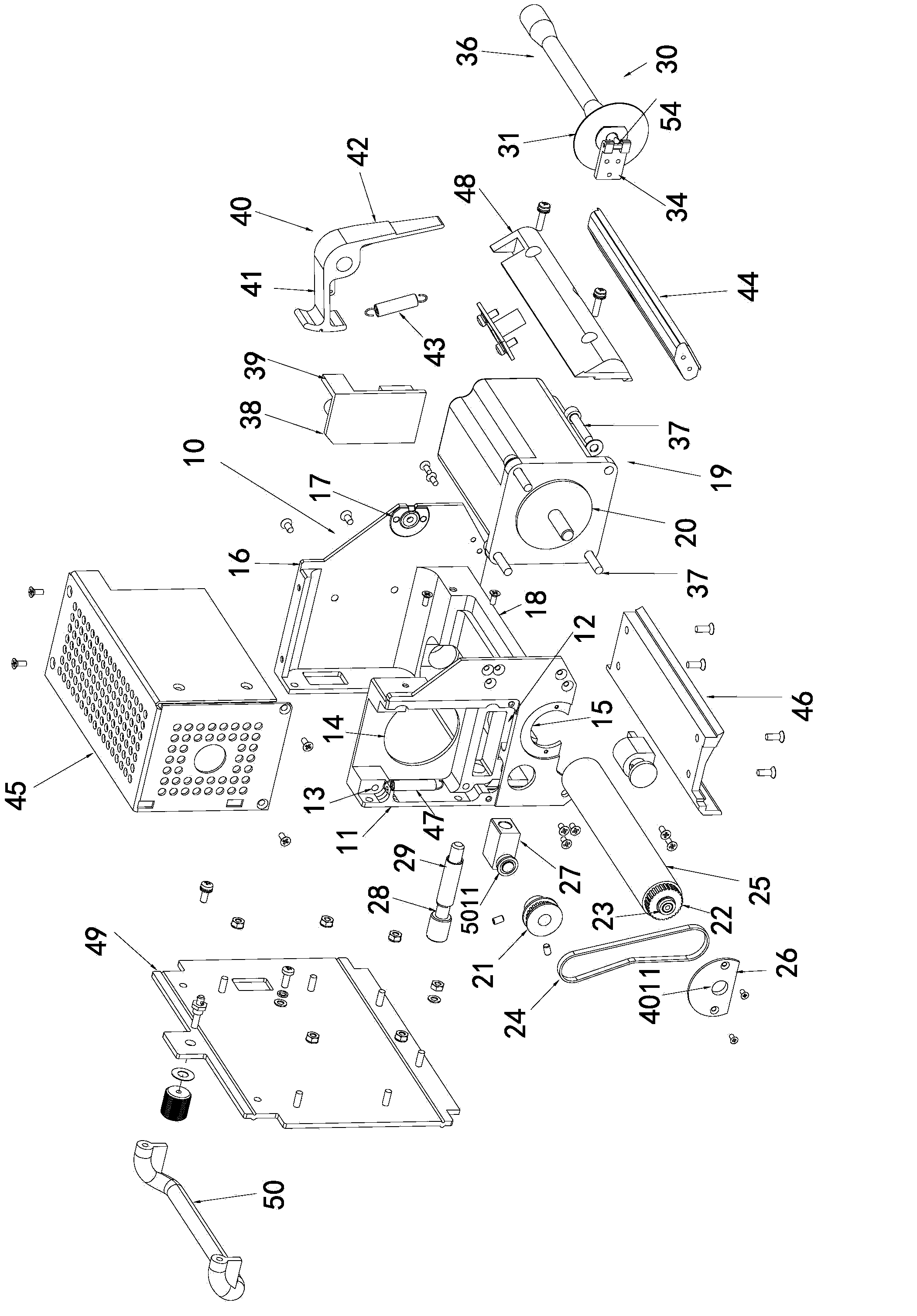

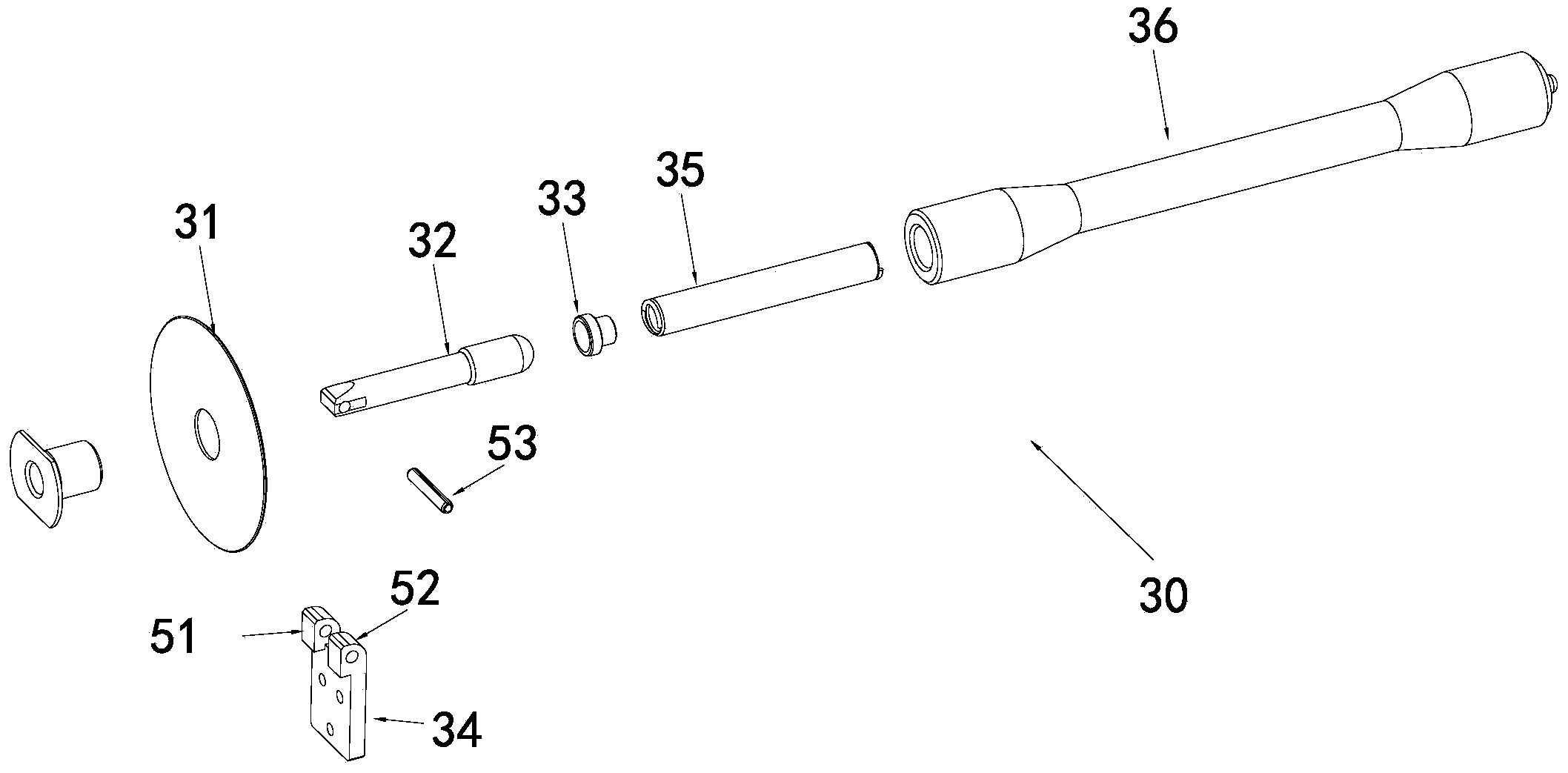

[0091] see figure 1 , 2 As shown, the printer base 3 provided in this embodiment mainly includes: a bearing member 10 , a motor 19 , a rotating wheel assembly, a rubber roller 25 , a tensioning assembly and a paper shaft assembly 30 . Its connection relationship and working principle are as follows:

[0092] The carrying member 10 is the main carrying mechanism of the main components of the base of the printer, and is composed of a horizontal carrying frame 18 , a first vertical mounting frame 11 , and a second vertical mounting frame 16 . The first vertical mounting frame 11 and the second vertical mounting frame 16 are respectively located on the left and right sides of the horizontal carrier frame 18 .

[0093] The motor 19 is used to drive the rubber roller 25 for conveying the printing paper to the print head to rotate, and the motor 19 is fixed on the top surface of the horizontal carrier 18 .

[0094] The rotating wheel assembly includes a driving wheel 21 and a driv...

Embodiment 2

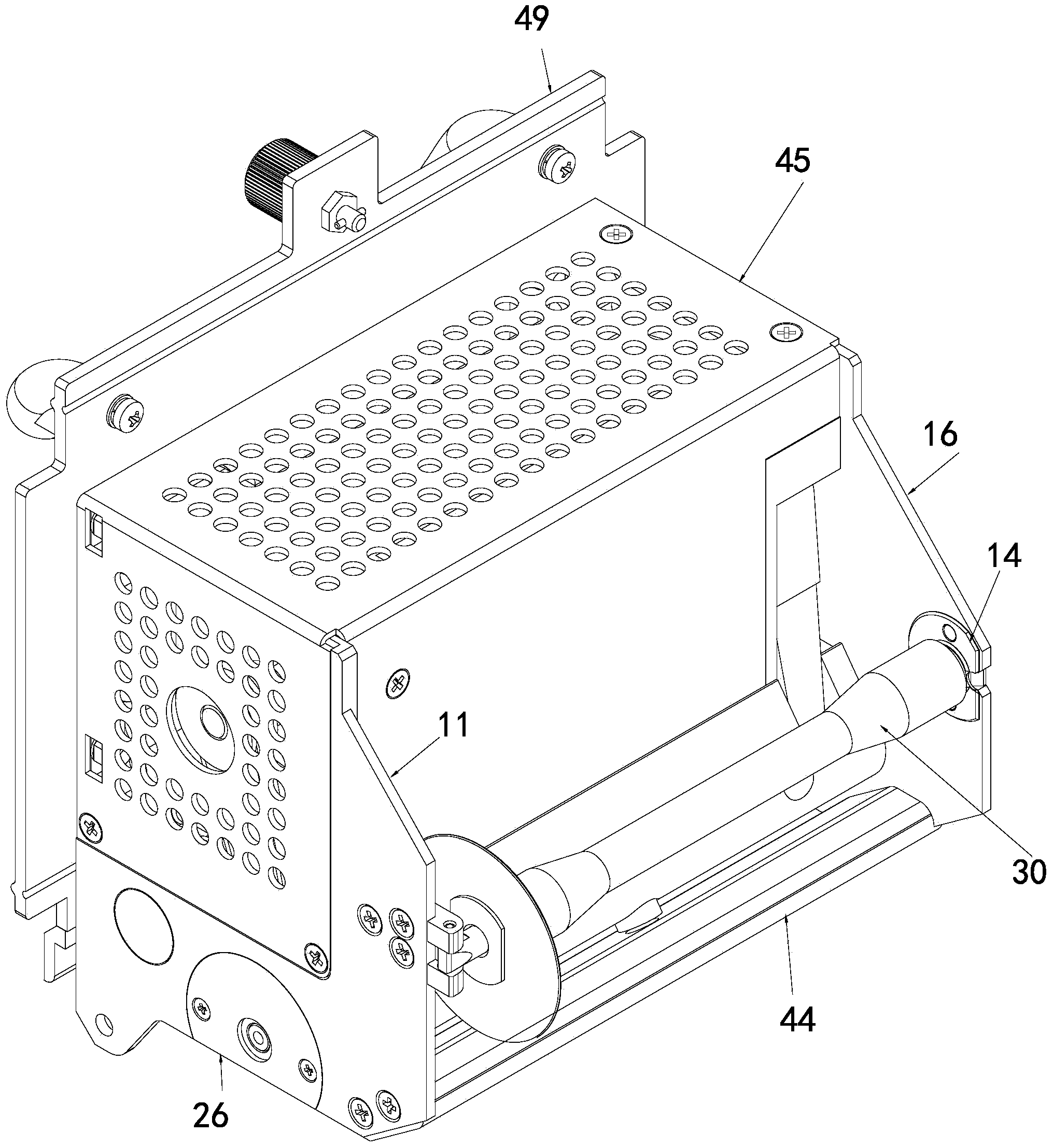

[0124] see Figure 4 , 5 As shown, the printer provided in this embodiment mainly includes: a casing 1 , a power drive assembly 2 , a printer base 3 , a print head assembly 4 , and a control module 5 . The connection relationship and working principle are as follows:

[0125] The casing 1 serves as the outer casing of the printer of this embodiment, and is used for accommodating various components of the printer.

[0126] The power drive assembly 2 is installed at the rear end of the casing 1. The power drive assembly 2 adopts a modular design and can be easily disassembled as a whole from the rear end of the casing 1. The power drive assembly 2 is used for the printer base 3 , the print head assembly 4 and the control module 5 provide driving power. Further structure and working principle are detailed in the description of Example 4.

[0127] The printer base 3 is mounted on the front end of the casing 1 , and adopts a modular design, which can be easily disassembled as a...

Embodiment 3

[0133] see Image 6 , 7 As shown, the print head assembly 4 provided in this embodiment mainly includes the following components: an adjustment plate 101 , a spring sheet 102 , a mounting plate 103 , and a print head 104 . Its assembly structure is as follows:

[0134]The adjustment plate 101 is used as the main bearing component of the print head assembly 4 , and is used for mounting the spring sheet 102 and the mounting plate 103 . A horizontal groove 1011 is provided on the top surface of the adjusting plate 101, the spring sheet 102 is limited in the groove 1011, the two ends of the spring sheet 102 are in contact with the ends of the groove 1011 respectively, and the groove 1011 is opposite to the spring sheet 102. Limiting is performed to prohibit the left and right and front and rear movements of the spring piece 102 in the horizontal direction.

[0135] The spring piece 102 in this embodiment is a long strip, the spring piece 102 is bent at the midpoint, and an incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com