Chufa washing method

A water chestnut and washing machine technology, applied in application, food processing, food science and other directions, can solve the problems of low cleaning efficiency, high labor intensity, and difficulty in cleaning water chestnuts, and achieve the effect of thorough decontamination and high cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

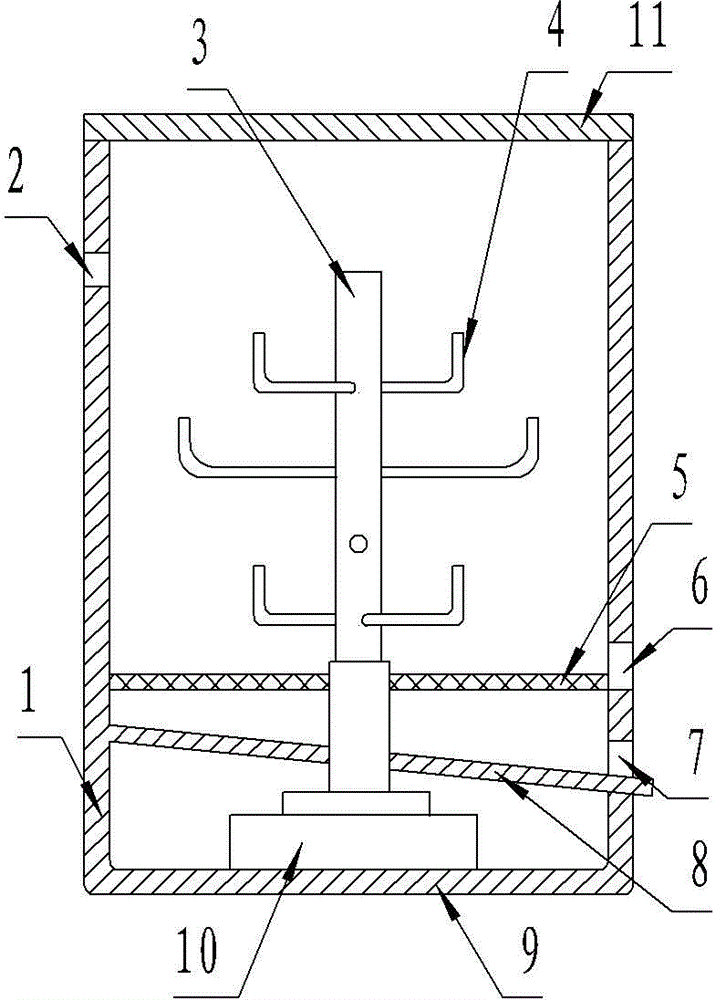

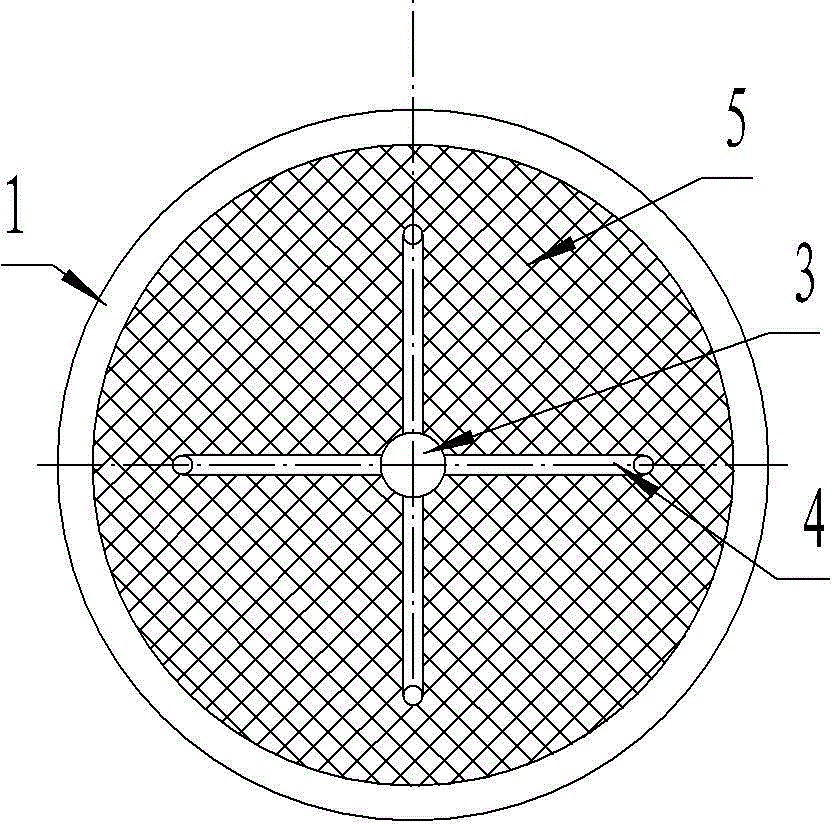

[0014] Such as figure 1 , figure 2 The shown water chestnut cleaning method includes using a water chestnut cleaning machine to clean the water chestnuts. The water chestnut cleaning machine includes a barrel body 1, and the barrel bottom of the barrel body 1 has two layers. A horizontal motor 10 is arranged between the barrels 9, and the power output shaft of the horizontal motor 10 passes through the bottom 8 of the upper layer of the barrel upwards, and is connected to drive a vertical shaft 3. The vertical shaft 3 is evenly provided with multiple rows of stirring rod groups, Each group of stirring rods includes at least four stirring rods 4 radially installed on the vertical shaft 3. The ends of the stirring rods 4 are bent upwards to fully stir the water chestnuts, so that the water chestnuts are squeezed and rubbed against each other, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com