3D printing production method of multi-flavor sandwiched food

A 3D printing and sandwich food technology, which is applied in bakery food, food preparation, dairy products, etc., can solve the problems of restricting the production types of sandwich food production lines and restricting the realization of blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better explain the present invention and facilitate the understanding of the technical solutions of the present invention, typical but non-limiting examples of the present invention are as follows.

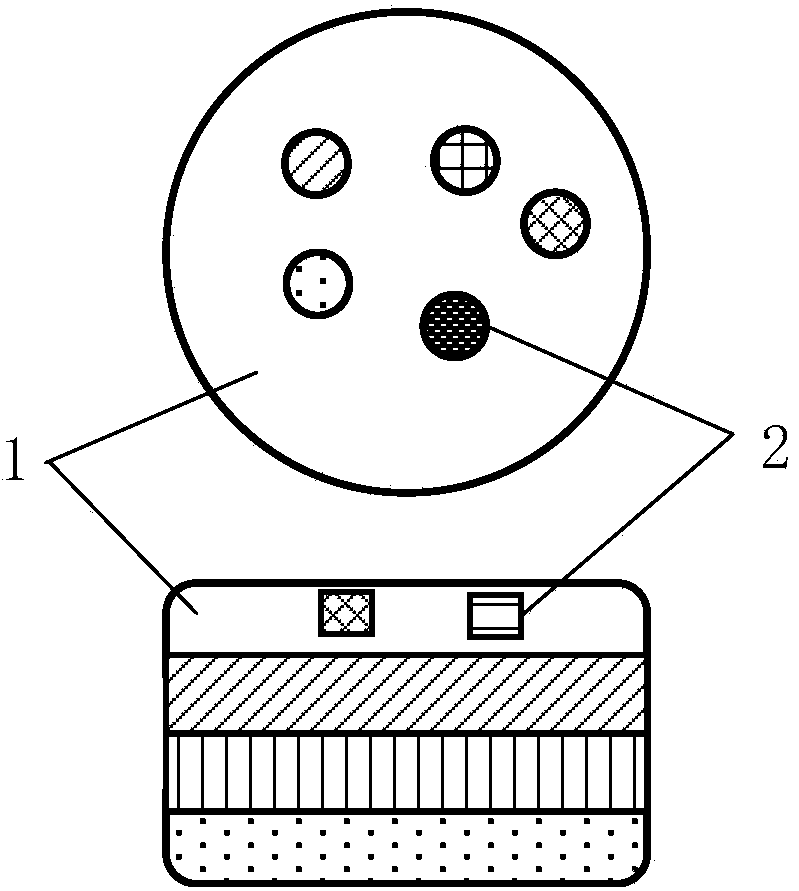

[0018] In the production of sandwich food, many 3D printing heads contain different food substrates (1) and sandwich materials (2).

[0019] According to the shape and taste of the design, the base material (1) and the sandwich material (2) can be printed with different spatial shapes and quantities, forming a variety of shapes and appearances, and each shape has different shapes and numbers of sandwiches. Can make food have various tastes.

[0020] The sandwich material (2) can realize various complicated spatial structures, and can also realize the closed structure food in which the sandwich material (2) is completely covered in the base material (1).

[0021] Using 3D printing technology, any food material can be combined. Chocolate, biscuits, ice cream, cream, fruit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com