Linear Reluctance Motor

A reluctance motor and linear technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of high vibration and noise, large thrust fluctuation, low thrust density, etc., to reduce copper consumption, improve thrust density, and cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

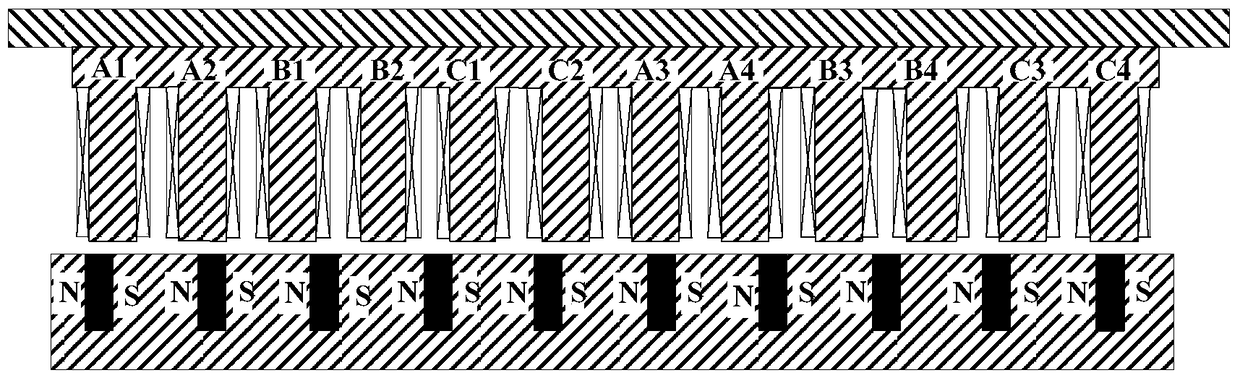

[0037] Specific implementation mode one: combine figure 1 Describe this embodiment, the linear reluctance motor described in this embodiment,

[0038] Including primary and secondary; there is an air gap between primary and secondary; the primary includes primary and secondary, and the primary includes primary core and primary winding; the primary core is in the shape of a flat plate, and the side of the air gap is grooved transversely to form 12 teeth , along the moving direction, a coil is wound on each tooth of the primary core, the primary winding is a 3-phase winding, a coil is wound on each tooth of the primary core, every two adjacent teeth and the upper The wound coils constitute a phase unit, and the winding directions of the coils on every adjacent two teeth of the two teeth forming a phase unit are opposite, and the two coils are connected in series; the whole motor has a total of 6 phase units, belonging to the same phase The phase unit coils are connected in ser...

specific Embodiment approach 2

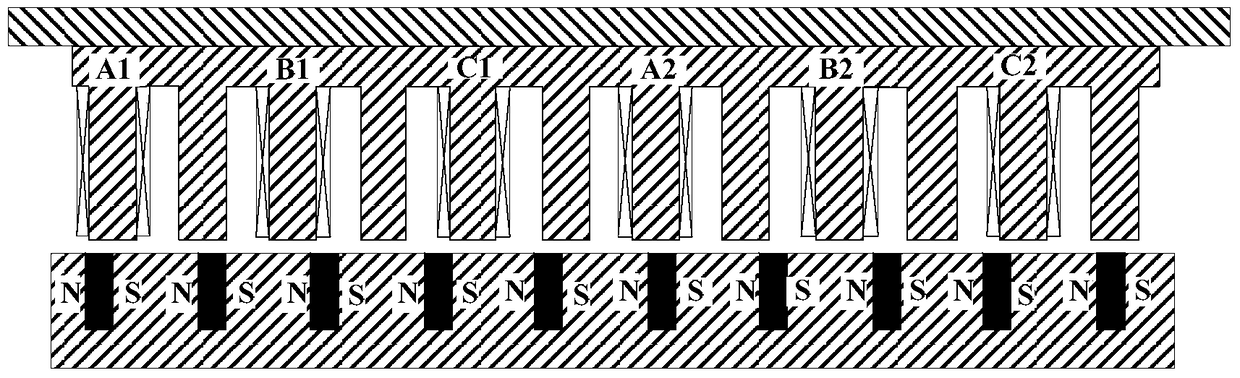

[0041] Specific implementation mode two: combination figure 2 Describe this embodiment, the linear reluctance motor described in this embodiment includes a primary and a secondary; there is an air gap between the primary and the secondary;

[0042] Primary includes primary core and primary winding;

[0043] The primary iron core is in the shape of a flat plate, and there are multiple slots on the side of the air gap in the transverse direction, and the formed teeth and slots are arranged alternately along the relative movement direction of the primary and secondary; along the movement direction, every other tooth in the primary iron core A coil is wound on the top, and the primary winding is a 3-phase winding, that is, the teeth with coils and the teeth without coils are arranged alternately along the moving direction, and each tooth and the coils wound on it constitute a phase unit;

[0044] The motor has three phase units in total, and the coils of the phase units belonging ...

specific Embodiment approach 3

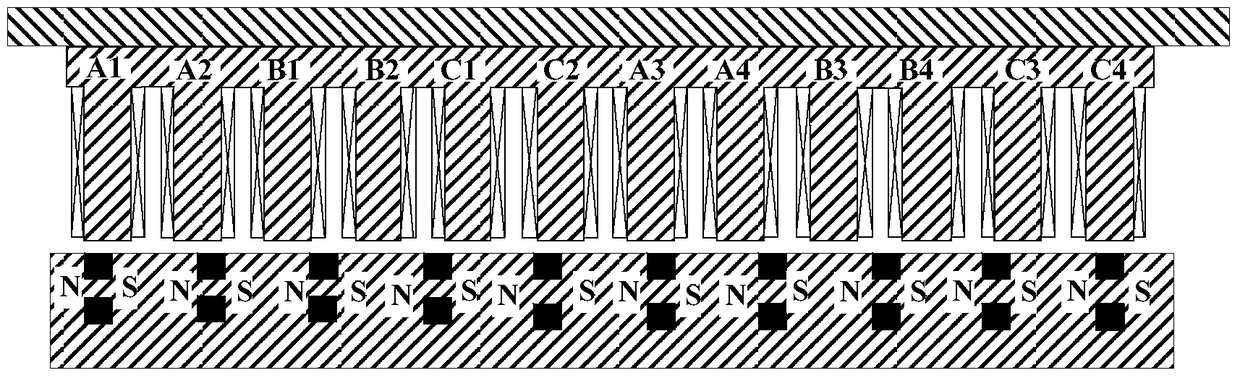

[0046] Specific embodiment three: the linear reluctance motor described in this embodiment,

[0047] The motor includes a primary and a secondary; there is an air gap between the primary and the secondary;

[0048] Primary includes primary core and primary winding;

[0049] The primary iron core is in the shape of a flat plate, and there are multiple slots along the transverse direction on the side of the air gap, and the formed teeth and slots are arranged alternately along the relative movement direction of the primary and secondary;

[0050] The number of secondary poles of the motor Z r with primary teeth number Z s satisfy the following relationship: Z s =mqZ r , q is the number of slots per pole and phase, and is a positive integer;

[0051] The primary winding is embedded in each slot, and the primary winding is a 3-phase symmetrical stacked winding;

[0052] The secondary includes a secondary iron core and a permanent magnet; the secondary iron core is in the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com