Optical-cable-embedded composite type leaky coaxial cable and manufacturing method thereof

A leaky coaxial cable, composite technology, applied in communication cables, cables, circuits, etc., can solve the problem of not satisfying the simultaneous installation of leaky coaxial cables and optical cables, leaky coaxial cables, and limited cable space area, etc. Performance advantage, changing environment, effect of increasing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical means and effects of the present invention in order to achieve the intended purpose of the invention, the following in conjunction with the accompanying drawings and preferred embodiments, the introduction of the embedded optical cable composite leaky coaxial cable and its manufacturing method according to the present invention Specific embodiments and structures will be described.

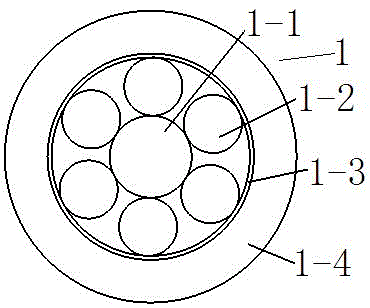

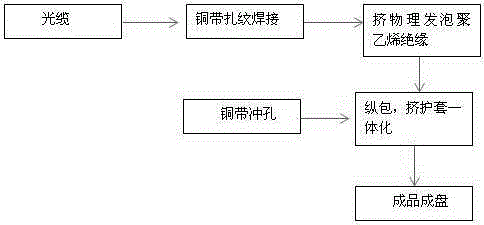

[0025] Refer to attached figure 1 , 2 , 3. The composite leaky coaxial cable with embedded optical cable includes optical cable 1, corrugated copper tube 2, polyethylene foam insulation layer 3, slotted copper tape 4 and polyolefin outer sheath 5; inside the corrugated copper tube 2 A fiber optic cable 1 is wrapped, and a polyethylene foam insulation layer is extruded outside the pricked copper pipe 2, and a slotted copper tape 4 is wrapped outside the polyethylene foam insulation layer 3, and a layer of slotted copper tape 4 is extruded outside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com