Interface thermal resistance measuring method in dissimilar metal compound molding process

A dissimilar metal and process interface technology, which is applied in the heating field of plastic processing of metal materials, can solve problems such as damage, inability to apply dissimilar metal forming interface thermal resistance measurement, contact thermocouple loosening, etc., and achieve the effect of avoiding contact loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

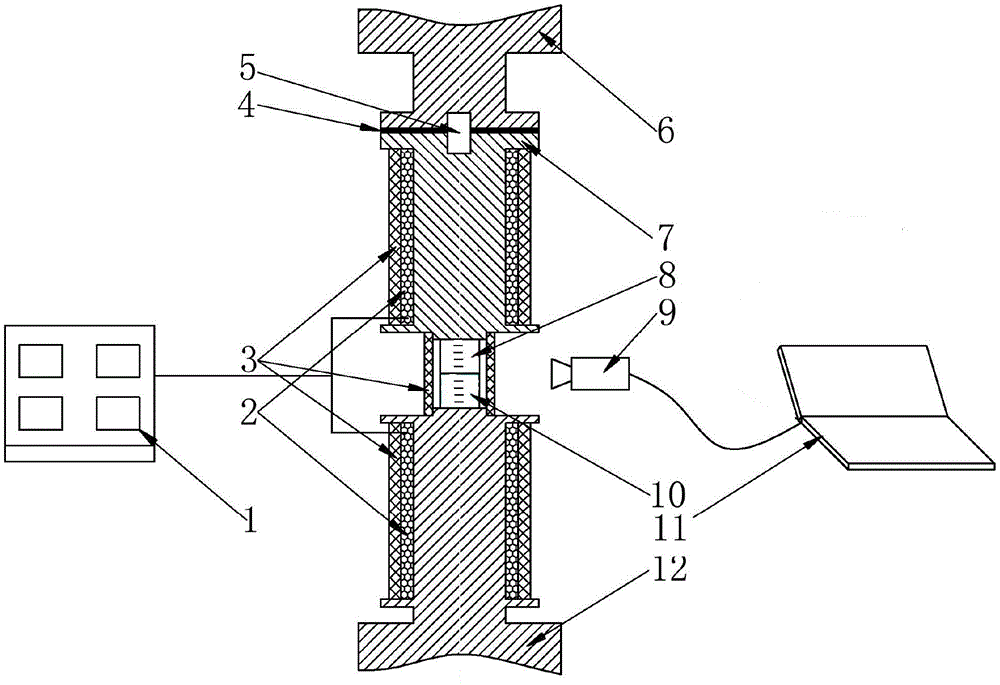

[0014] Specific implementation mode one: combine figure 1 Describe this embodiment, the method of this embodiment includes the following steps: step 1, mark a number of equidistant holes along the longitudinal direction on the dissimilar metal blank, and then fix it between the punch and die of the press, wherein the dissimilar metal blank is formed by the first blank 8 and the second blank 10 are connected together, the contact surface of the first blank 8 and the second blank 10 is an interface and the two are metals with different materials, the dissimilar metal blanks are clamped on the Instron electronic universal material testing machine 6, and the A certain pre-pressure makes the mold clamp the dissimilar metal blank; it ensures the stability of the heat source on both sides of the dissimilar material.

[0015] Step 2. Heat the punch 7 and the die 12 respectively: set the predetermined heating temperature of the punch 7 and the die 12 through the intelligent temperature...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 Describe this embodiment. In step 1 of this embodiment, mark a number of equidistant holes along the axial direction on the dissimilar metal blank, and use a vernier caliper to accurately measure and divide the surface of the dissimilar metal blank to mark and punch holes. The distribution of the measuring points of the two materials is guaranteed to be consistent. . Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the heating temperature of the male mold in step 2 of this embodiment is 300°C-350°C, and the heating temperature of the concave mold is 200°C-250°C. Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com