On-line detection system for enameled wire surface paint film thickness

A paint film thickness and detection system technology, applied in the direction of electric/magnetic thickness measurement, electromagnetic measurement devices, etc., can solve the problems of mercury pollution by low-pressure mercury method, affecting the popularity, and increasing the production cost of manufacturers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For ease of understanding, the specific implementation structure and workflow of the present invention are further elaborated below in conjunction with the diagrams:

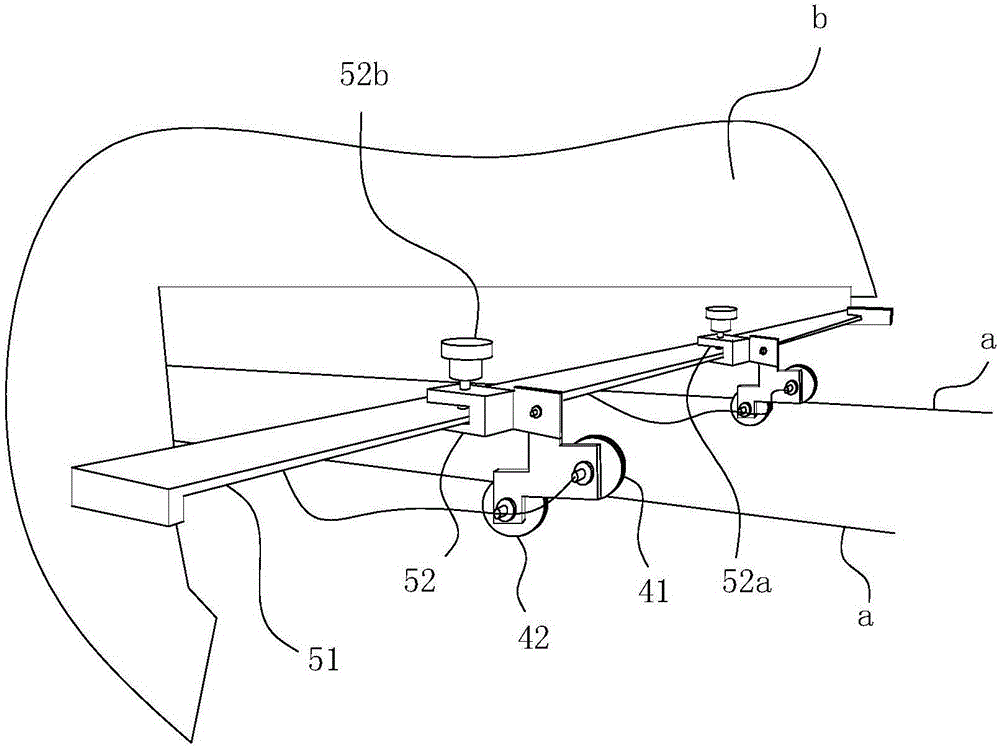

[0030] The specific circuit structure of this system is as follows: figure 1 As shown, it includes the discharge assembly 10 that provides the enameled wire a to discharge the voltage, the crimping wheel part that connects the discharge assembly to form the discharge end, and the voltage sampling sensor 30 located at the frame of the enamelling machine or at the ground contact such as the take-up wheel. The voltage sampling sensor 30 is used to collect the value of the ground voltage of the enameled wire a after being powered, and send it to the control box (that is, the control alarm component 20) for data statistics. Rely on the comparison between the collected pressure drop value and the pressure drop value data pre-stored in the control box under normal conditions to judge whether there is no paint or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com