Embedded leak-proof joint system

A leak-proof and pre-embedded technology, applied in the direction of pipe/pipe joint/fitting, sealing surface connection, sleeve/socket connection, etc., can solve the problems of no secondary drainage, potential safety hazards, joints without water seal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below by specific examples.

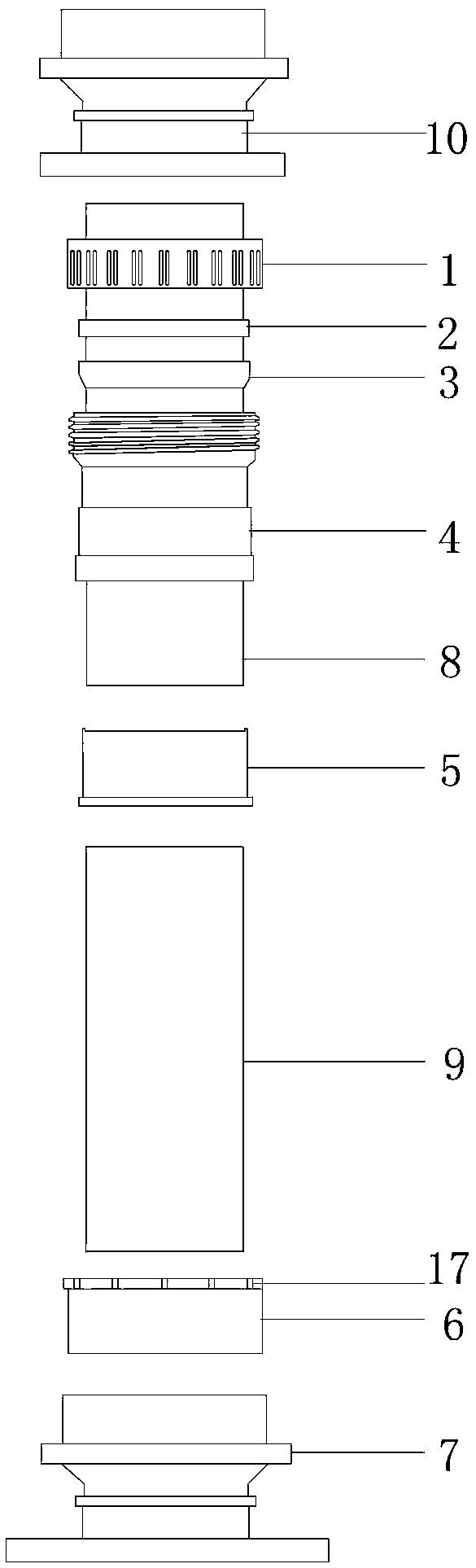

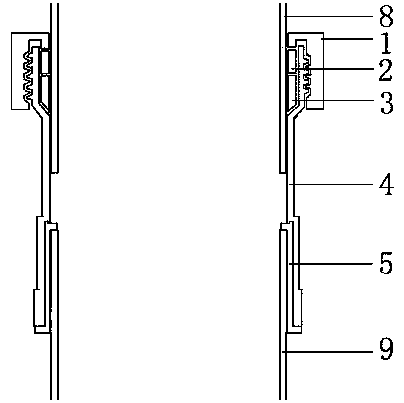

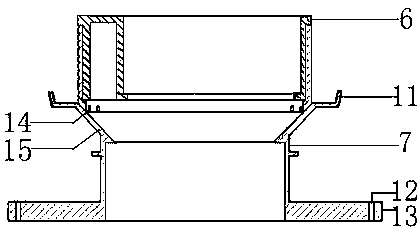

[0026] The pre-embedded leak-proof joint system of the embodiment includes expansion joints and leak-proof joints, such as figure 2 It is an expansion joint structure, image 3 , Figure 4 For leak-proof joint construction, such as figure 1 As shown, the upper end pipe 8 of the expansion joint is connected to the upper leak-proof joint 10, and the lower end pipe 9 of the expansion joint is connected to the lower leak-proof joint.

[0027] Such as figure 2 As shown, the expansion joint includes the expansion joint upper cover 1, the middle cup body 4, the lower cup body 5, the expansion joint compression ring 2 and the waterproof rubber ring 3, the expansion joint lower cup body 5 is set on the lower end pipe 9, and the expansion joint middle The cup body 4 is set on the upper pipe 8, the inner diameter of the upper end of the middle cup body 4 is larger than the outer diameter of the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com