Free on-off vacuum valve device for high gas tightness and manufacture method thereof

A vacuum valve, high airtight technology, applied in valve device, lift valve, valve details, etc., to achieve the effect of reliable sealing performance, high sealing performance, and reducing the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

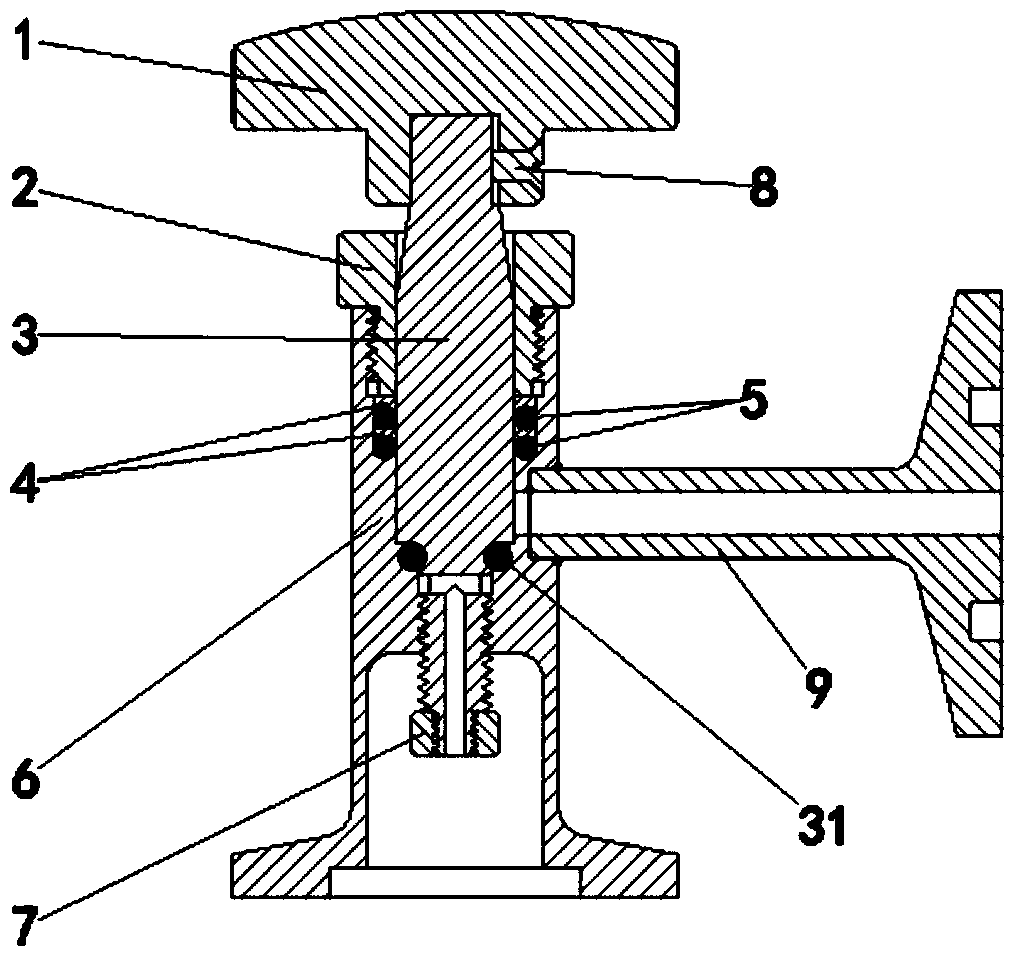

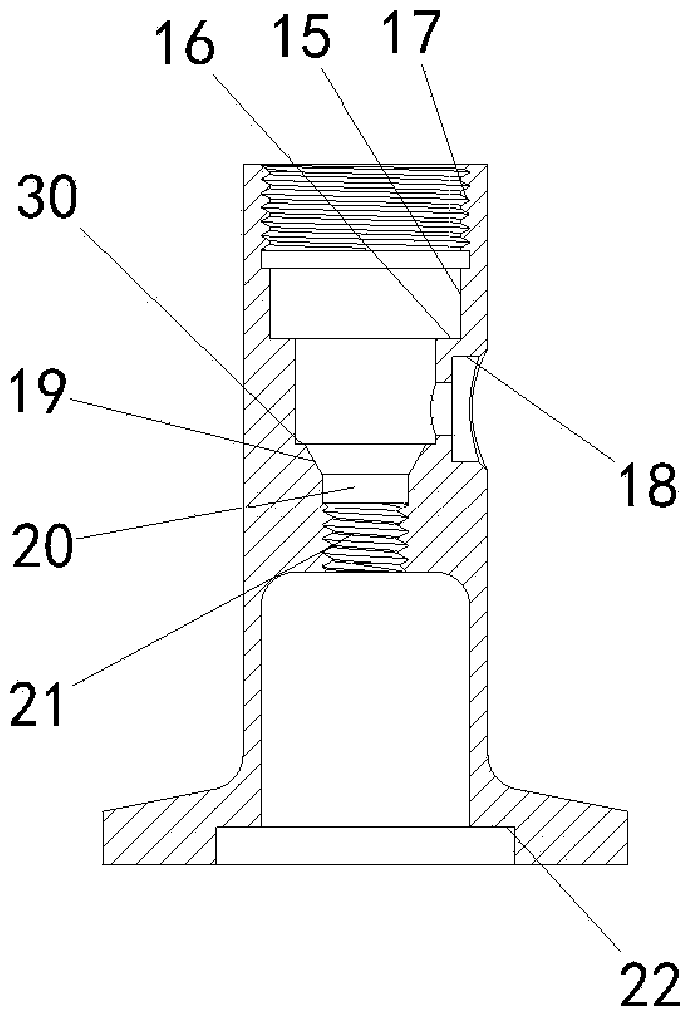

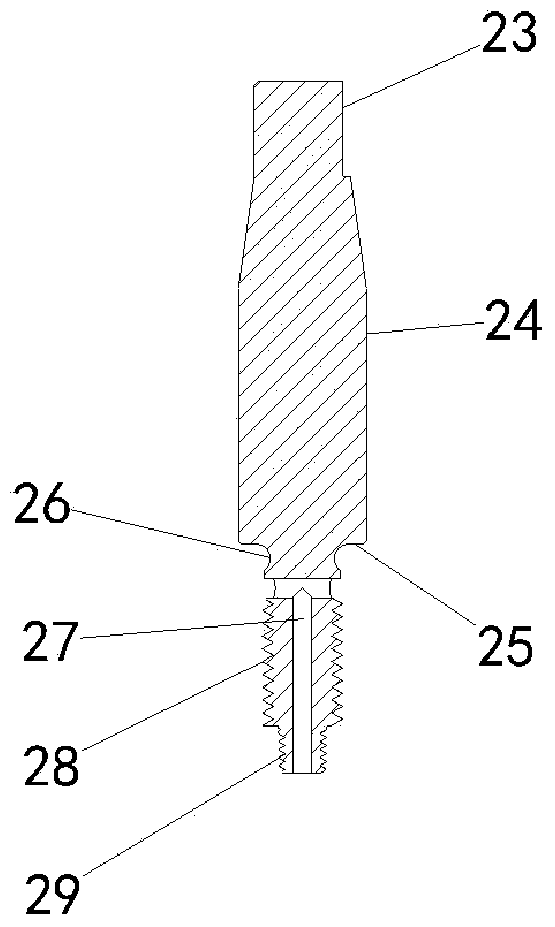

[0033] Such as figure 1 As shown, the invented vacuum valve device with free opening and closing and high airtightness is composed of a handle 1, a compression nut 2, a valve core 3, a compression ring 4, an upper seal 5, a valve body 6, and a gear nut 7 , anti-loosening screw 8, lower seal 31 and vacuum joint 9, characterized in that the valve body 6 is a hollow columnar body, the uppermost end of the inner hole is the valve body compression thread 17, which is next to the valve body compression thread 17 The inner circular surface and the stepped surface are respectively the valve body sealing inner circular surface 15 and the valve body sealing plane 16, the counterbore structure on one side of the valve body 6 is the valve body side interface 18, and the middle part of the inner hole of the valve body 6 is made with a The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com