Special driving compound gear box of cold-rolling stainless steel sheet recoiling machine set

A technology of cold-rolling stainless steel and thin plate coils, applied in transmission boxes, gear transmission devices, belts/chains/gears, etc., which can solve the problems of large number of equipment, low use efficiency, and large volume, and achieve small transmission space and high use efficiency Tall, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

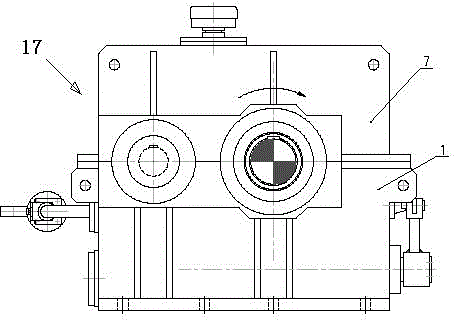

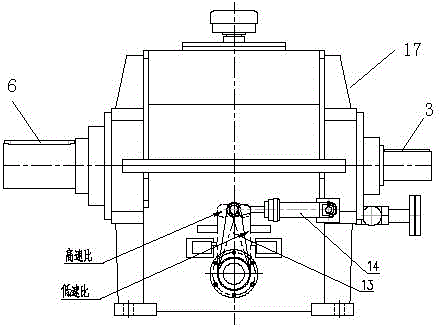

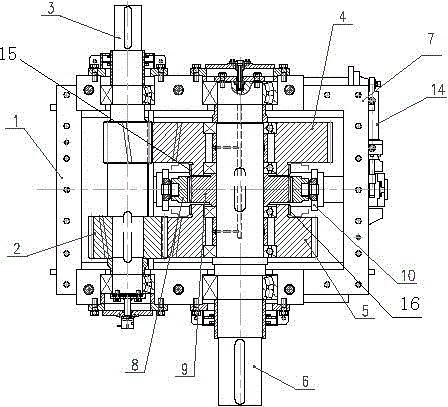

[0017] Such as Figure 1-4 shown

[0018] A special composite gearbox for driving a cold-rolled stainless steel sheet coiling unit, including an upper box body 7 and a lower box body 1, such as figure 1 , The upper box body 7 and the lower box body 1 are connected by bolts in the mid-section, and the input gear shaft 3 is installed in the lower box body 1 . The two ends of the gear shaft 3 are respectively equipped with bearings, which are respectively installed in the upper box body 7 and the lower box body box 1, and are meshed with the first shift gear 4; image 3 , the lower end of the gear shaft 3 is equipped with a gear 2, the gear 2 meshes with the second shift gear 5, the first shift gear 4 and the second shift gear 5 are respectively set on the corresponding bearings, and the bearings are installed on the output On the shaft 6, the first sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com