A piston accumulator

An accumulator, piston-type technology, applied in the direction of actuator accumulator, fluid pressure actuating device, mechanical equipment, etc., can solve problems such as sealing failure, achieve reliable sealing performance, ensure sealing performance, ensure normal movement and The effect of speed of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

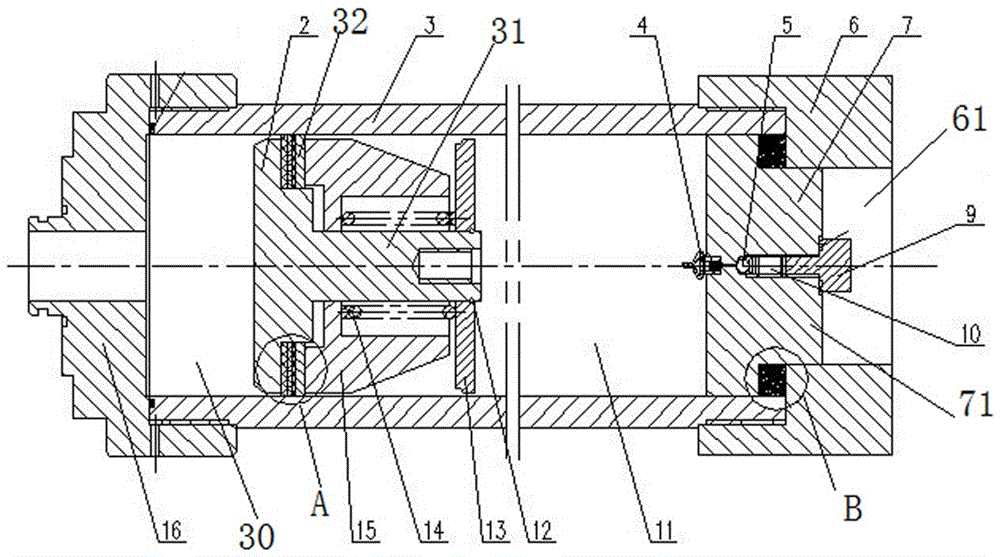

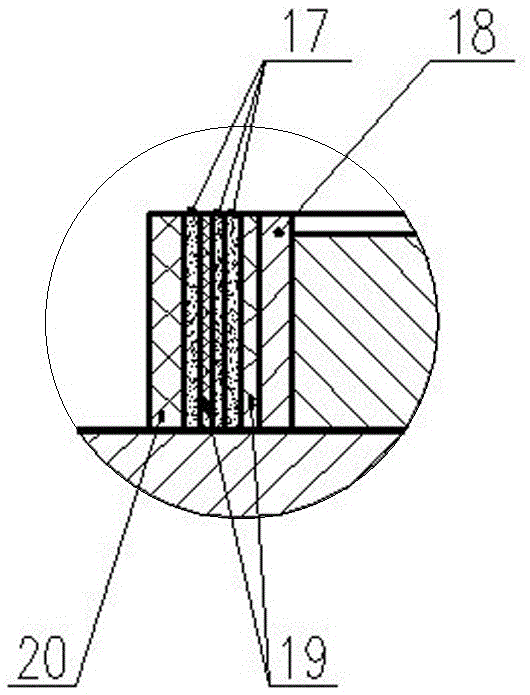

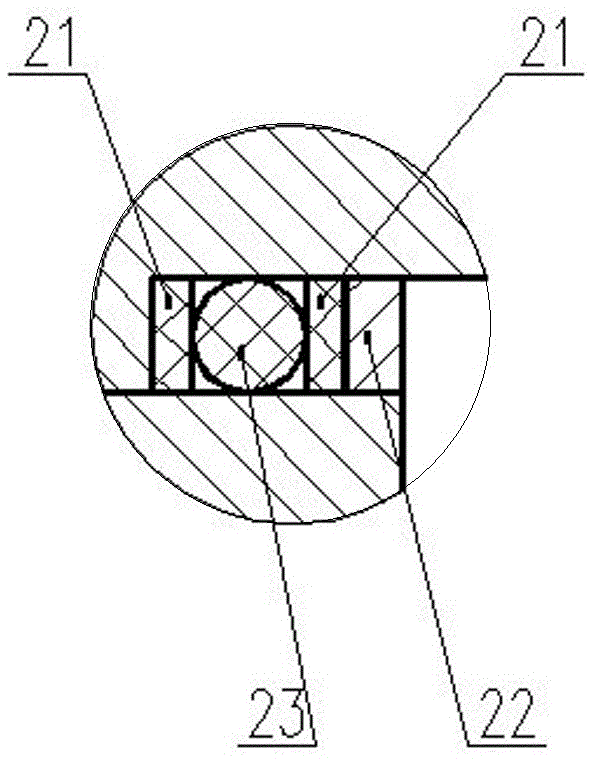

[0022] Such as Figure 1 to Figure 3 As shown, an embodiment of an accumulator equipped with a sealed piston device, the accumulator in this embodiment includes a cylinder body 3 extending in the front and rear directions, and a sealed piston structure is arranged in the cylinder body 3, and the sealed piston structure includes Move the piston 2 assembled in the cylinder body 3 in the forward and backward direction, which divides the inner chamber of the cylinder body into an oil chamber 30 and an air chamber 11, and the outer peripheral surface of the piston 2 is coaxially fitted with a radial sealing ring that cooperates with the cylinder body 3 to move and seal 32. The piston 2 is provided with a thrust surface that cooperates with the thrust limit of the radial seal ring 32 at the rear of the radial seal ring 32. The guide connecting column 31 extending forward in the direction is set on the guiding connecting column 31 with a compression spring 14 extending in the front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com