Gas compressor impeller

A compressor and impeller technology, applied in the field of compressor impeller, can solve the problems of reduced flow area, gas flow blockage of supercharger, increased fuel consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

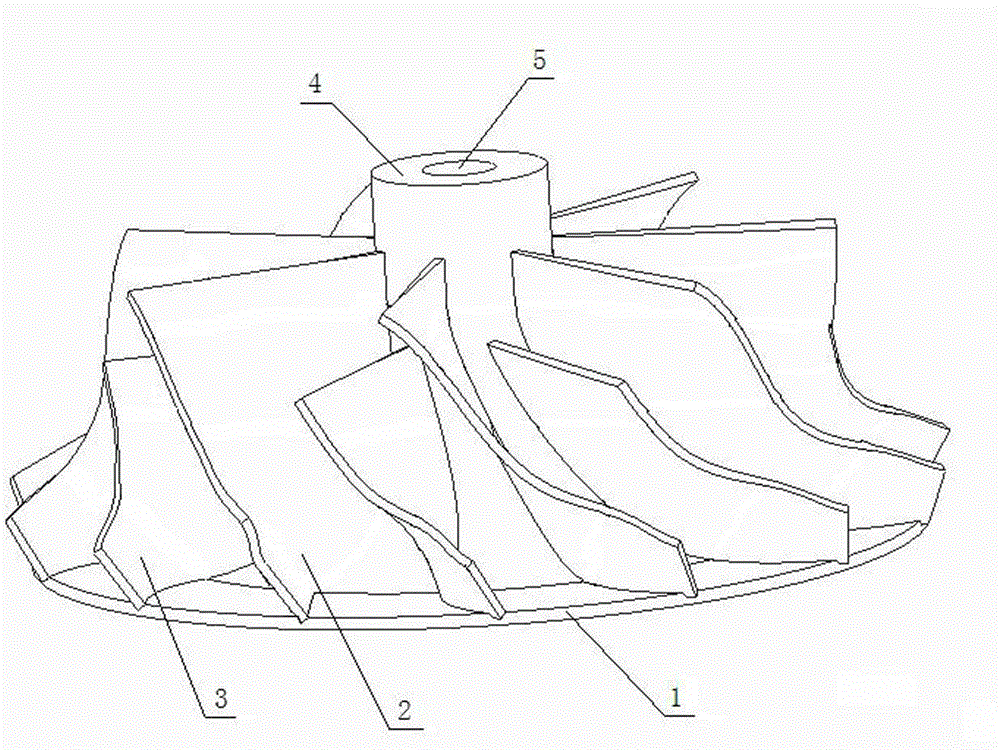

[0013] Such as figure 1 and figure 2 As shown, the compressor impeller of the present invention includes a wheel disc 1, which is a disc with a shaft hole 5 processed in its center and a shaft sleeve 4 arranged in the center of one side. The inner diameter of the bushing 4 is equal to and corresponds to the shaft hole on the wheel disc 1 . The shape of the sleeve 4 is trumpet-shaped, so that the diameter of one end thereof is larger than that of the other end. The big end of the axle sleeve 4 is cast integrally with the wheel disc 1 . Blades are evenly distributed around the shaft sleeve 4, and the blades and the shaft sleeve 4 are cast as one. One end of the short blade 3 far away from the wheel disk 1 is retracted inward, and the retracted length is 1 / 5 of the total length of the blade, so that the length of the blade on the end of the shaft sleeve 4 far away from the wheel disk 1 is arranged in a long and short end shape. Among the adjacent blades, one impeller is a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com