Organic silicon modified waterborne polyurethane leather coating agent and preparation method

A leather finishing agent, water-based polyurethane technology, applied in the direction of polyurea/polyurethane coating, leather surface treatment, small raw hide/large raw hide/leather/fur treatment, etc. Significant changes, etc., to achieve the effect of uniform and stable emulsion, improved water resistance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

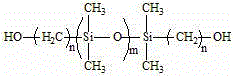

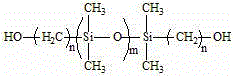

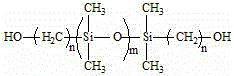

Method used

Image

Examples

Embodiment 1

[0121]Add 16.05g of IPDI, 40.00g of PPG2000, 4.61g of castor oil, and 2.12g of hydroxypropyl silicone oil after dehydration into a four-necked flask equipped with an electric stirrer and a reflux condenser, and add 3 to 5 drops of dilauric acid dilaurate Butyl tin, react at 80°C for 2~3h to obtain a siloxane-modified prepolymer. Add 3.87g of DMPA and 15g of acetone to the prepolymer, and continue to react at 80°C for 3~4h to obtain a prepolymer with hydrophilic terminal isocyanate groups. Then lower the temperature to 50°C, add 2.92gTEA to neutralize and form a salt, and stir for 30min. Dissolve 1.00 g of ethylenediamine in 164.66 g of deionized water, slowly add it to the high-speed shear prepolymer, emulsify and disperse for 30 minutes, and finally distill off the acetone under reduced pressure to obtain a silicone-modified water-based polyurethane emulsion.

[0122] The appearance of the prepared emulsion is milky white with slight bluish light. After being centrifuged in...

Embodiment 2

[0125] Add 16.05g of IPDI, 40.00g of PPG2000, 4.61g of castor oil, and 3.60g of hydroxypropyl silicone oil after dehydration into a four-necked flask equipped with an electric stirrer and a reflux condenser, and add 3 to 5 drops of dilauric acid dilaurate Butyl tin, react at 80°C for 2~3h to obtain a siloxane-modified prepolymer. Add 3.87g of DMPA and 15g of acetone to the prepolymer, and continue to react at 80°C for 3~4h to obtain a prepolymer with hydrophilic terminal isocyanate groups. Then lower the temperature to 50°C, add 2.92gTEA to neutralize and form a salt, and stir for 30min. Dissolve 1.00 g of ethylenediamine in 168.13 g of deionized water, slowly add it to the high-speed shear prepolymer, emulsify and disperse for 30 minutes, and finally distill off the acetone under reduced pressure to obtain a silicone-modified water-based polyurethane emulsion.

[0126] The appearance of the prepared emulsion is milky white with slight bluish light. After being centrifuged i...

Embodiment 3

[0128] Add 16.05g of IPDI, 40.00g of PPG2000, 4.61g of castor oil, and 5.15g of hydroxypropyl silicone oil after dehydration into a four-necked flask equipped with an electric stirrer and a reflux condenser, and drop 3 to 5 drops of dilauric acid dilaurate Butyl tin, react at 80°C for 2~3h to obtain a siloxane-modified prepolymer. Add 3.87g of DMPA and 15g of acetone to the prepolymer, and continue to react at 80°C for 3~4h to obtain a prepolymer with hydrophilic terminal isocyanate groups. Then lower the temperature to 50°C, add 2.92gTEA to neutralize and form a salt, and stir for 30min. Dissolve 1.00 g of ethylenediamine in 171.75 g of deionized water, slowly add it to the high-speed shear prepolymer, emulsify and disperse for 30 minutes, and finally distill off the acetone under reduced pressure to obtain a silicone-modified water-based polyurethane emulsion.

[0129] The appearance of the prepared emulsion is milky white with bluish light. After being centrifuged in a de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com