Vacuum quantifying tank

A quantitative tank and vacuum technology, applied in the field of vacuum quantitative tank, can solve the problems affecting the quality of castings, oxidation and slag inclusion, etc., and achieve more regular motion trajectory, stable gas flow and stable driving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

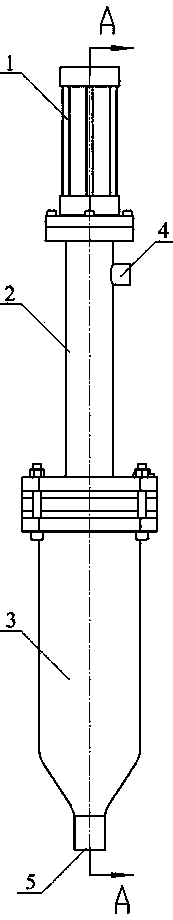

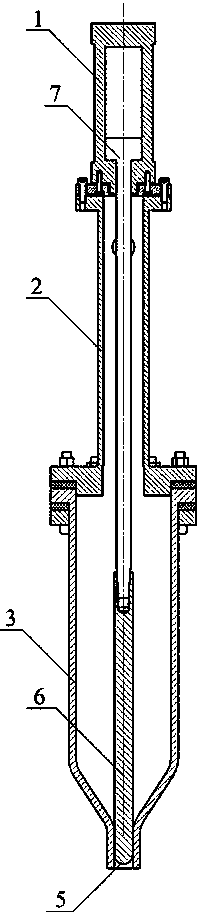

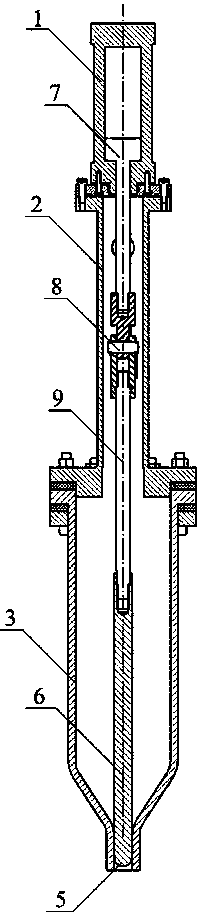

[0030] see figure 1 and figure 2 , figure 1 and figure 2 The first embodiment of the vacuum quantitative tank of the present invention is shown. The vacuum quantitative tank includes a cylinder 1, a bearing seat 2 and a tank body 3 which are sequentially sealed and connected in series. The cavities of the bearing seat 2 and the tank body 3 are connected to form Vacuum chamber. The bearing seat 2 is provided with a vacuum port joint 4 to control the vacuum degree of the vacuum cavity. A tank opening 5 is provided at the bottom of the tank body 3 , and a valve core 6 for sealing the tank opening 5 is provided in the cavity of the tank body 3 . The piston rod 7 inside the cylinder 1 is connected to the valve core 6, and the piston rod 7 drives the valve core 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com