Electromagnetic iron-removing machine

An iron remover and electromagnetic technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of easy clogging of soft magnetic nets, difficulty in removing ferromagnetic slag, etc., and achieve convenient and quick cleaning, good iron removal effect, Good clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

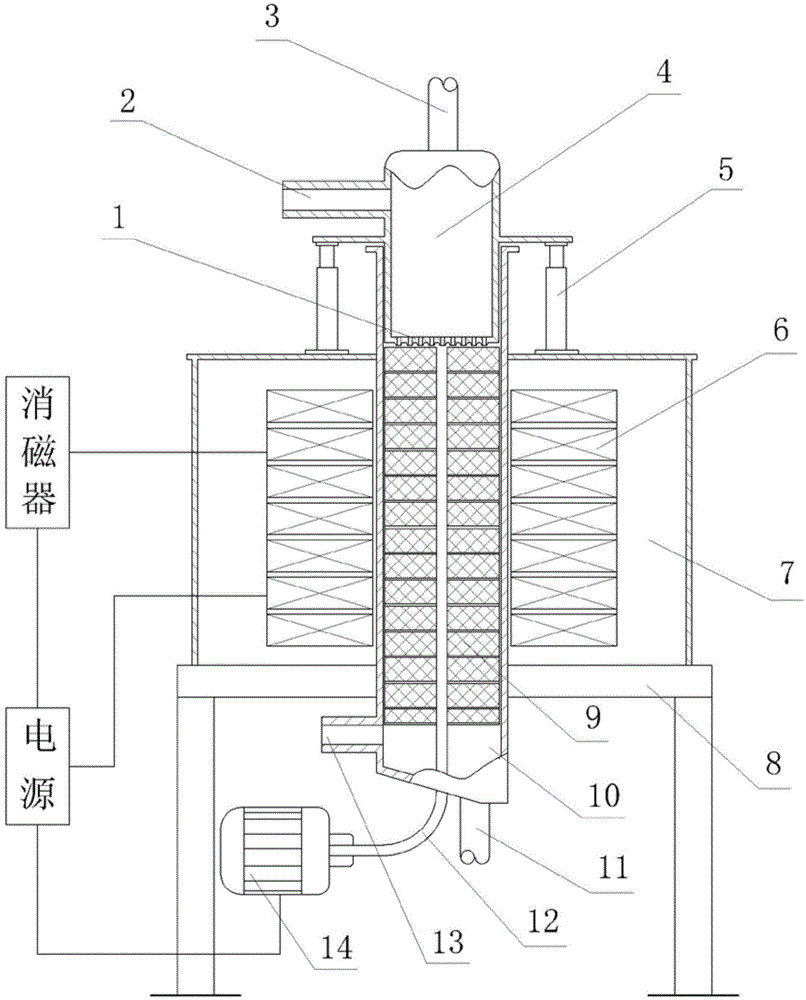

[0022] like figure 1 As shown, an electromagnetic iron remover includes a frame 8, an inner cylinder 10, a cooling box 7, an electromagnetic coil 6, a degausser and a power supply, the inner cylinder 10 is installed on the frame 8, and the electromagnetic coil 6 around the outside of the inner cylinder 10, the lower end of the inner cylinder 10 is provided with a feed port 13 and a slag discharge port 11, and the inner cylinder 10 is filled with soft magnetic steel bristles 9, which are cake-shaped , to be superimposed and filled in several layers, and the soft magnetic steel wool 9 is made into a cake shape to make the gaps in the soft magnetic steel wool 9 more uniform, and a round hole is set in the middle of the soft magnetic steel wool 9, and the soft magnetic steel wool 9 A vibrating rod 12 is installed in the round hole of the magnetic steel wool 9, and the vibrating rod 12 is connected with a vibrating motor 14. The upper end of the inner cylinder 10 is sleeved with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com