Drive induction method of single layer multipoint mutual capacitive touch screen

A single-layer multi-point, mutual-capacitance technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problem that the touch form cannot be applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

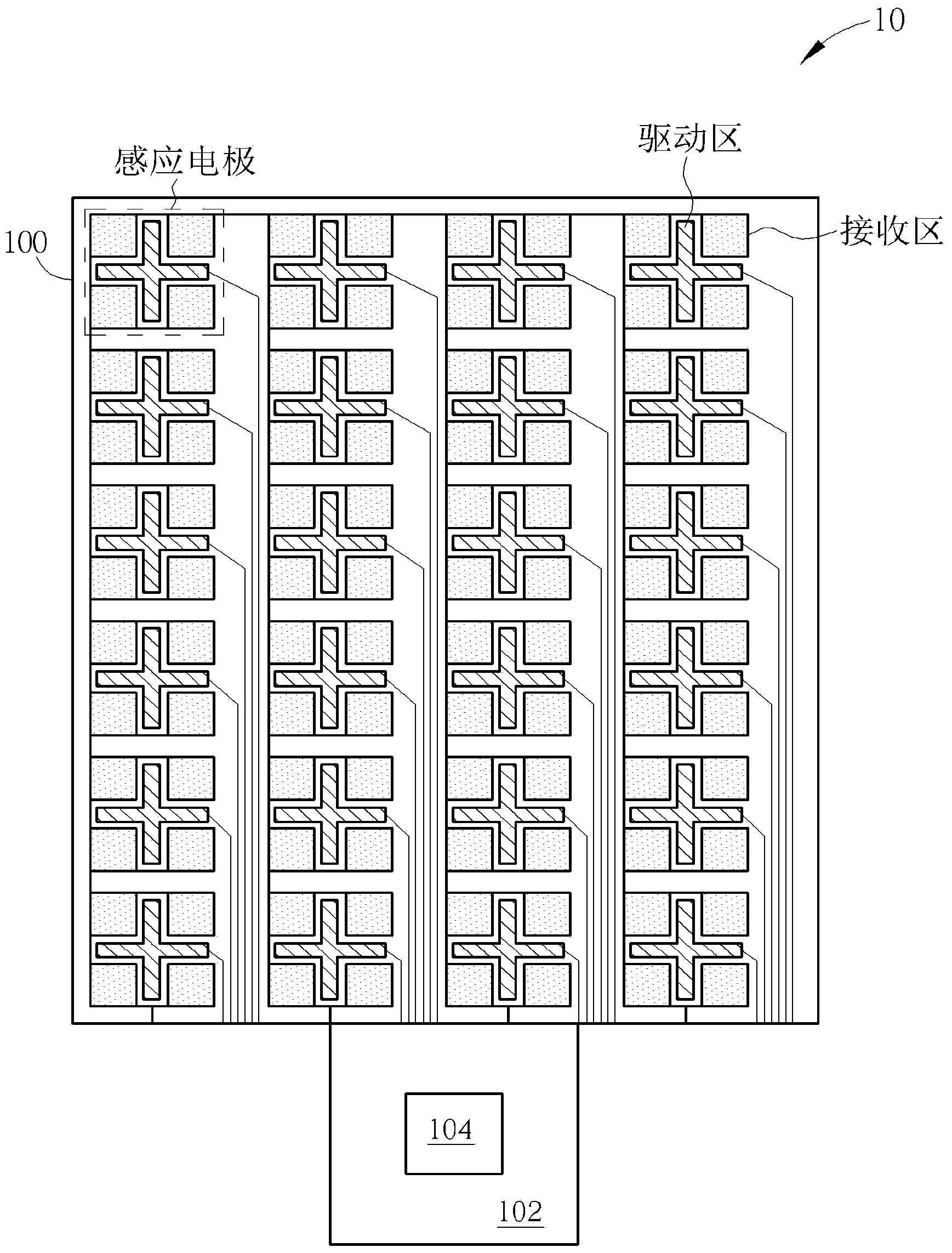

[0016] Please refer to figure 1 , figure 1 It is a schematic structural diagram of a single-layer multi-point mutual capacitive touch screen 10 according to an embodiment of the present invention. Such as figure 1 As shown, the single-layer multi-point mutual capacitive touch screen 10 includes a substrate 100 , a flexible printed circuit board (Flexible Printed Circuit board, FPC) 102 and a control circuit 104 . In the single-layer multi-point mutual capacitive touch screen 10 , each sensing electrode is disposed on the substrate 100 and consists of a driving area and a receiving area. For example, in figure 1 Among the sensing electrodes, the slashed part is the driving area, and the dotted part is the receiving area. In other embodiments, the shapes and ranges of the driving region and the receiving region can be appropriately adjusted according to different applications, but are not limited thereto. The flexible printed circuit board 102 is disposed on one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com