Test device and method for testing whether a workpiece is positioned correctly

A technology for detecting devices and workpieces, which can be used in measurement devices, re-radiation, general control systems, etc., and can solve problems such as workpiece damage, increased cost, and labor waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

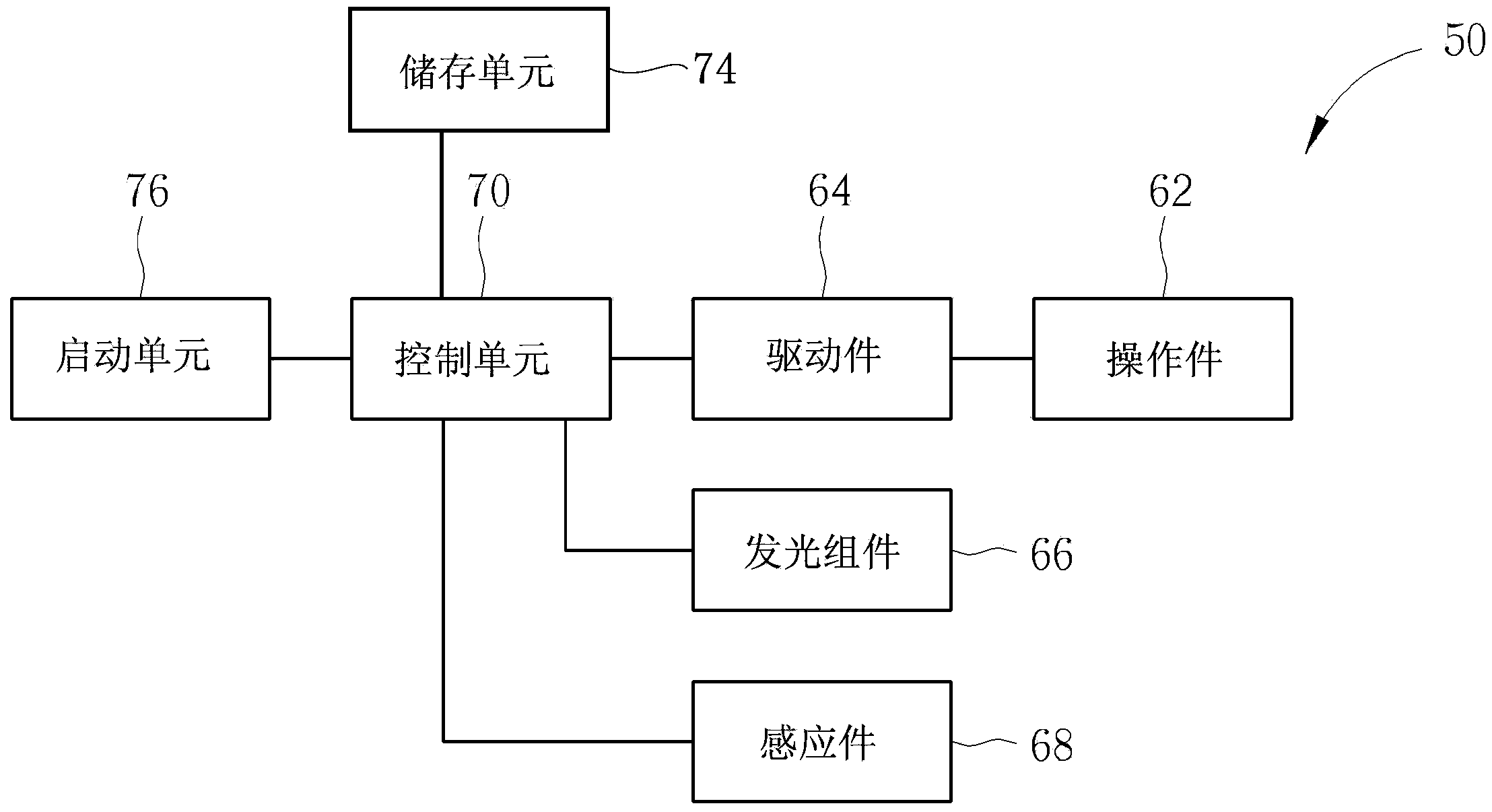

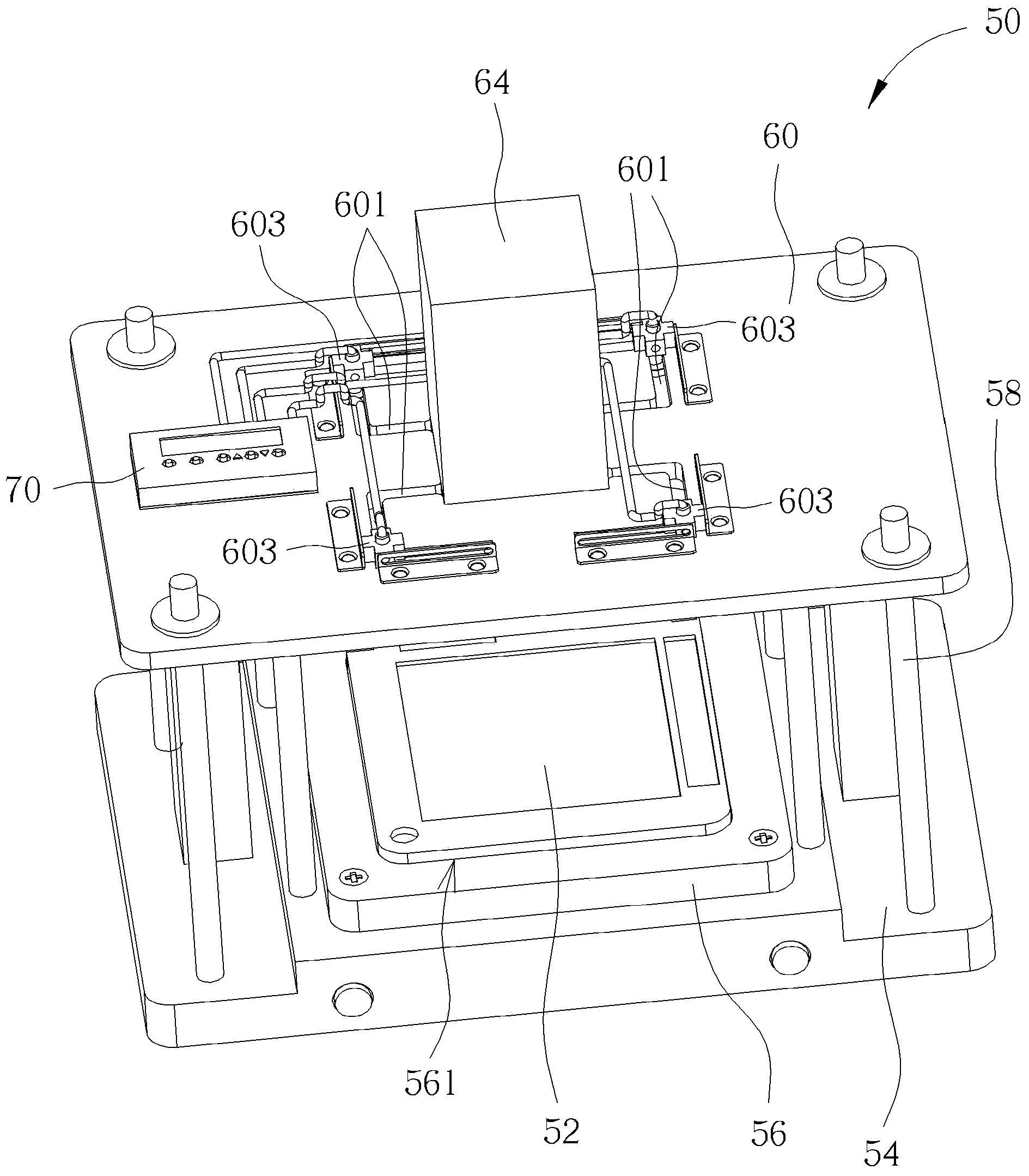

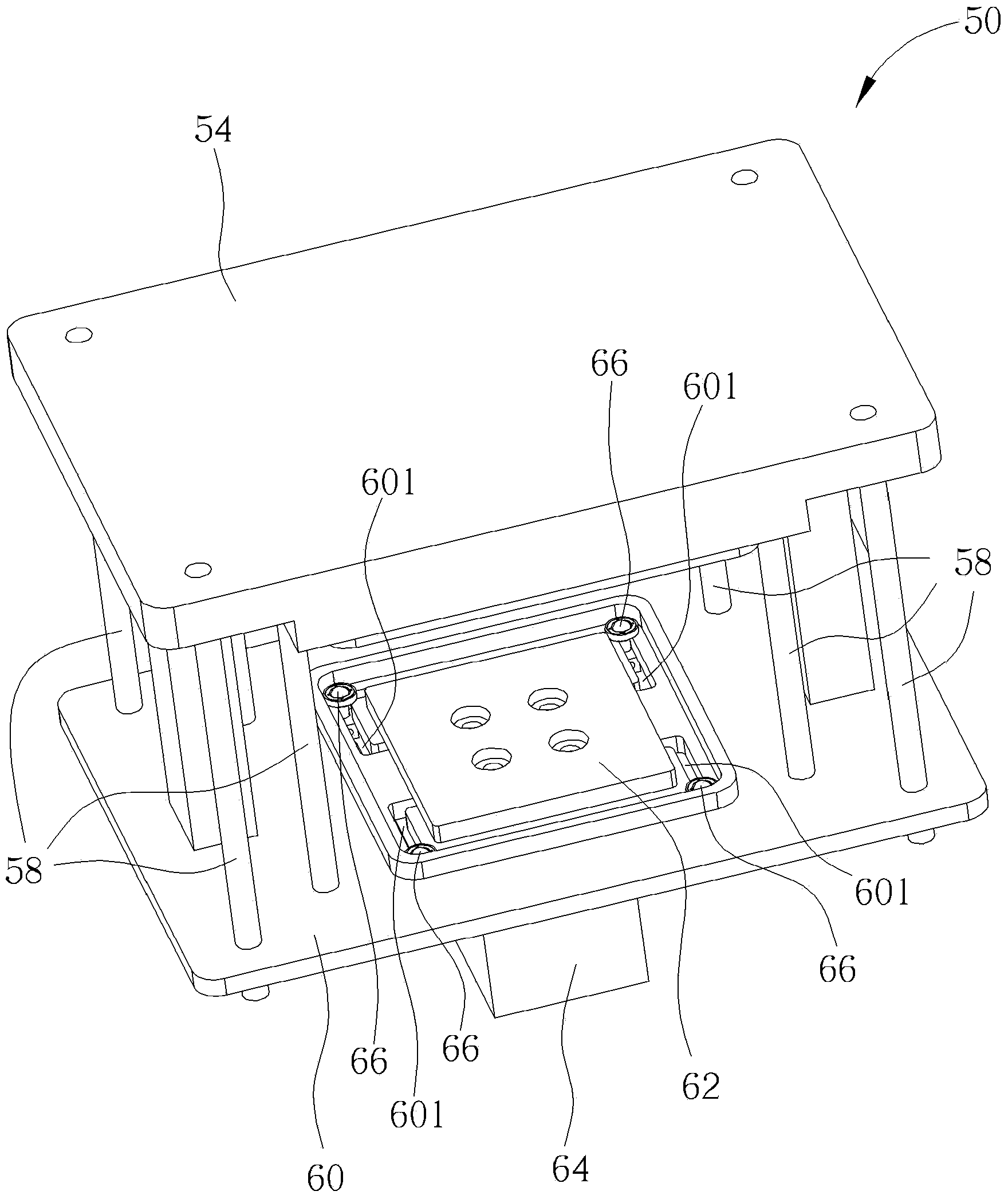

[0032] Please refer to figure 1 and figure 2 , figure 1 It is a functional block diagram of a detection device 50 according to an embodiment of the present invention, figure 2It is a schematic diagram of a detection device 50 according to an embodiment of the present invention. The detection device 50 is used to detect whether a workpiece 52 is placed correctly. The detection device 50 includes a base 54, a positioning member 56, at least one connecting member 58, a platform 60, an operating member 62, a driving member 64, at least one light emitting The assembly 66 , at least one sensor 68 and a control unit 70 . The positioning member 56 is installed on the base 54, and the positioning member 56 is provided with a positioning structure 561, such as a positioning groove, which is used to place the positioning workpiece 52, such as figure 2 shown. The positioning member 56 can be a fixture, and different positioning members 56 can be replaced according to workpieces 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com