The Method of Preventing Paper Web Turning Up for Pulp Machine

A pulping machine and paper web technology, applied in the papermaking, papermaking, wet end of the paper machine, etc., can solve the problems of pulp agglomeration accumulating on the scraper, affecting the operation of the pulping machine, long processing time, etc. Turn over, improve threading efficiency and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

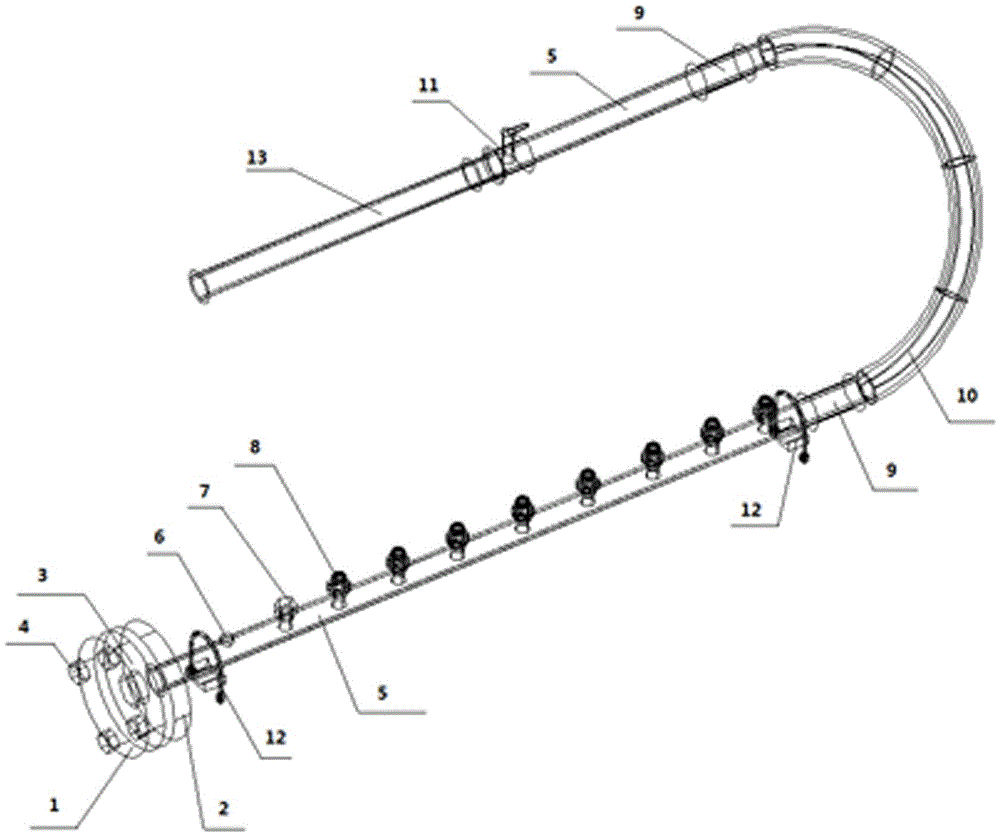

[0022] As shown in the figure, the device used in the method of preventing the paper web from turning up in the pulp board machine includes a stainless steel pipe 5, a hose 10, a valve 11, and a spray system pipe 13. The stainless steel pipe 5 is provided with a spray hole 6, and the spray hole 6 is provided on the stainless steel pipe 5. A stainless steel nut 7 is welded at the hole 6, a sprinkler head 8 is installed on the stainless steel nut 7, a flange 2 is connected to one end of the stainless steel pipe 5, and a flange gasket 3 and a flange cover are installed on the flange 2 through a fastener 4 1. The other end of the stainless steel pipe 5 is connected to the hose 10 through the joint 9, the hose 10 is connected to another stainless steel pipe 5 through the joint 9, and the other stainless steel pipe 5 is connected to the sprinkler system pipe 13 through the valve 11. The hose 10 is a steel wire braided rubber hose; the stainless steel pipe 5 is fixed on the net roller...

Embodiment 2

[0025] As shown in the figure, the device used in the method of preventing the paper web from turning up in the pulp board machine includes a stainless steel pipe 5, a hose 10, a valve 11, and a spray system pipe 13. The stainless steel pipe 5 is provided with a spray hole 6, and the spray hole 6 is provided on the stainless steel pipe 5. A stainless steel nut 7 is welded at the hole 6, a sprinkler head 8 is installed on the stainless steel nut 7, a flange 2 is connected to one end of the stainless steel pipe 5, and a flange gasket 3 and a flange cover are installed on the flange 2 through a fastener 4 1. The other end of the stainless steel pipe 5 is connected to the hose 10 through the joint 9, the hose 10 is connected to another stainless steel pipe 5 through the joint 9, and the other stainless steel pipe 5 is connected to the sprinkler system pipe 13 through the valve 11. The hose 10 is a steel wire braided rubber hose; the stainless steel pipe 5 is fixed on the net roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com