A kind of conveying device and conveying chain group

A transmission device and transmission chain technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as tilting and scattering, lack of transmission devices, and unsolvable problems, and achieve adjustable and accurate adjustment of the limit distance High degree of anti-rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

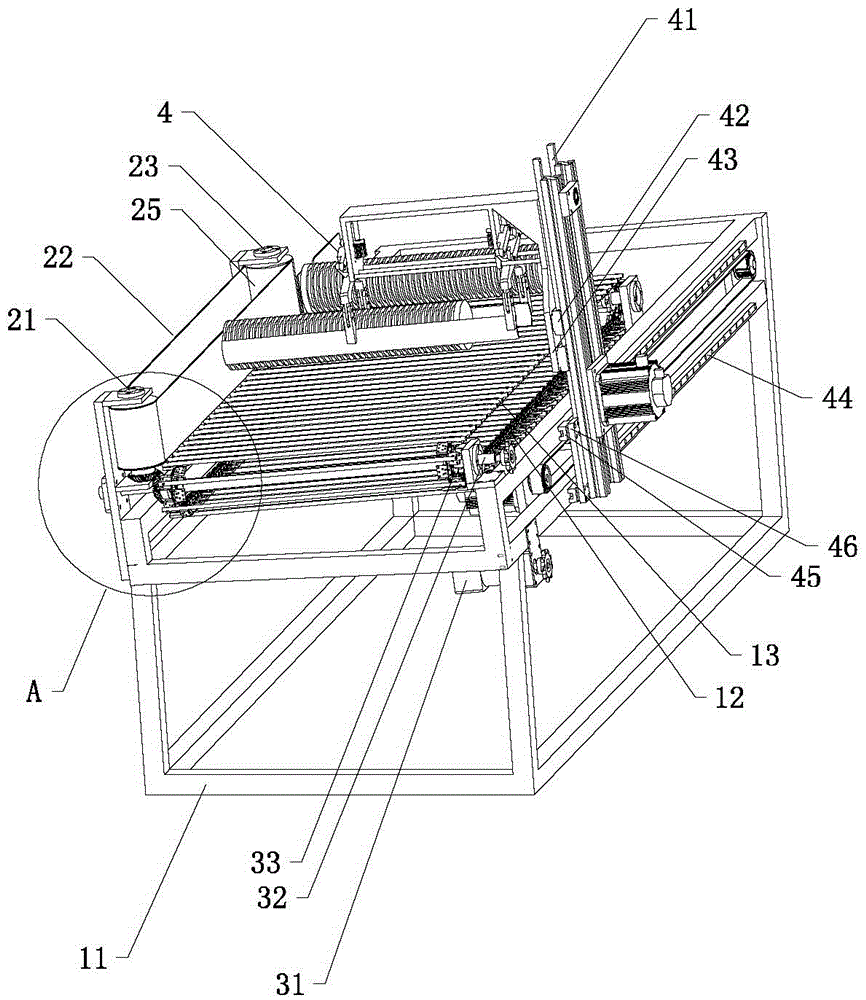

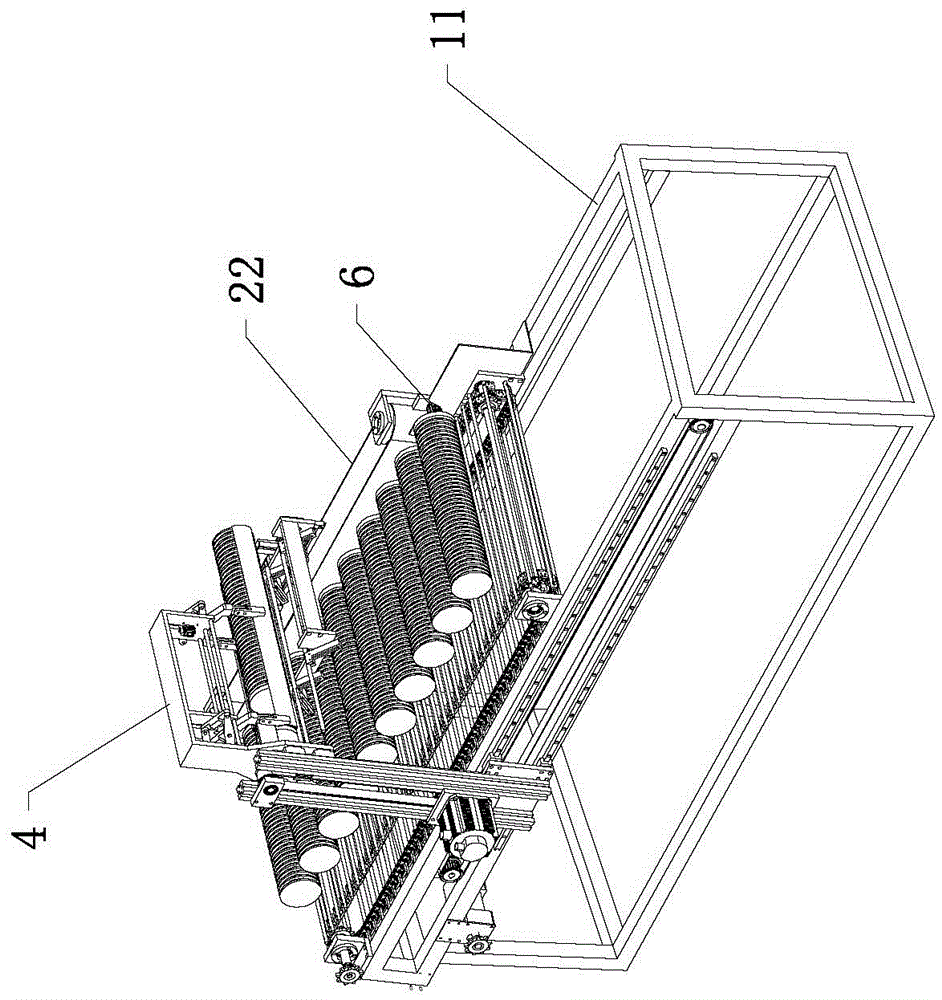

[0050] like Figure 1 to Figure 5As shown, a transmission device in this embodiment includes a transmission support frame 11, a driving device, a transmission chain set, an abutting device and a bevel gear set. The transmission chain group includes two transmission chains 12 and a plurality of limit rods 13, the transmission chain group includes two transmission chains 12 and a plurality of limit rods 13, and each transmission chain 12 includes a plurality of chain links, and the chain links One side plate is set as a right-angle plate 121, and the right-angle plates 121 of two adjacent chain links of the same conveyor chain 12 are respectively located on both sides of the conveyor chain 12, and the right-angle plate 121 is provided with two rows of fixing holes 122, and two rows of fixing holes 122 Specifically, the first row and the second row, the centers of the fixing holes in the second row are located on the center bisector of the two adjacent fixing holes in the first r...

Embodiment 2

[0056] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. On the basis of Embodiment 1, this embodiment also includes a plurality of adjustable fittings 14. The adjustable fittings 14 are provided with a plurality of adjustment holes 141 and fitting fixing holes 142122 corresponding to the fixing holes 122 of the rectangular plate 121. The accessory 14 is installed in the fixing hole 122 of the direct plate through the accessory fixing hole 142122 through a pin or a bolt, and the limit rod 13 is detachably fixed to the adjustable accessory through a pin or a bolt to connect the through hole 131 and the accessory fixing hole 142122 14.

Embodiment 3

[0058] The main technical solutions of this embodiment are basically the same as those of Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 2, and will not be repeated here. In this embodiment, a plurality of adjustment holes 141 are arranged in two rows, specifically a first row and a second row, and the center of the adjustment holes 141 in the second row is located at the center bisector of two adjacent adjustment holes 141 in the first row.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com