Light curing 3D printing device and printing method

A 3D printing and light-curing technology, applied in the printing field, can solve the problems of high cost, extremely high liquid level flatness, complicated production process, etc., and achieve the effect of simple printing method, easy operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

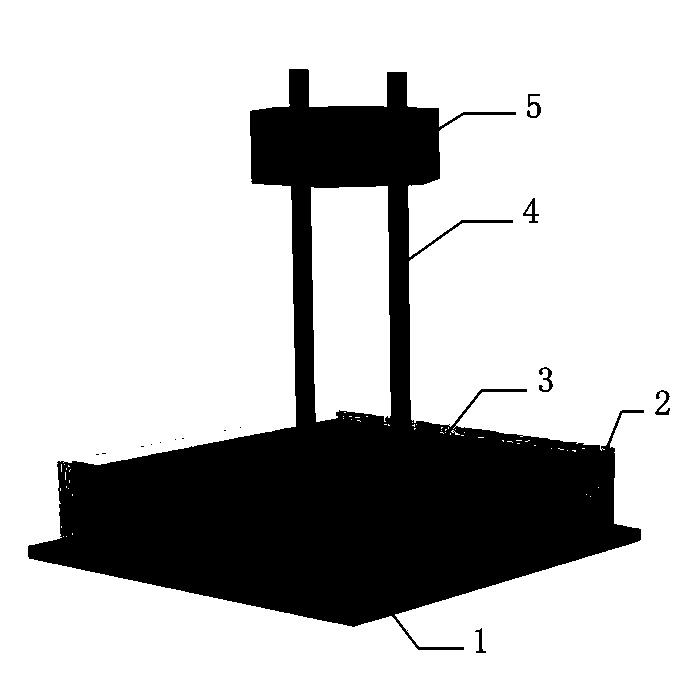

[0025] Embodiment 1, combining figure 1 , Install the developing module 1 on the bottom of the container tank 2, place the container 2 vertically with the notch facing upwards, install the 3 working platform on the 4 screw, connect the 4 screw to the 5 lifting motor, and obtain power through the 5 lifting motor so that Drive the 3 working platform to move up and down in the 2 container groove.

Embodiment 2

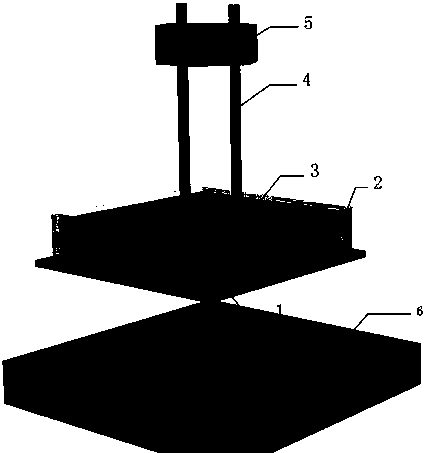

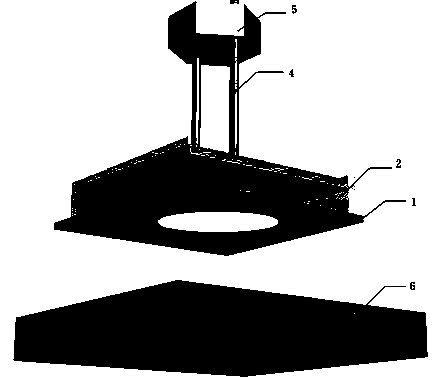

[0026] Embodiment two, in order to further illustrate the present invention, now in conjunction with figure 1 , figure 2 , image 3 The printing method involved in the present invention will be further described.

[0027] The first step is to inject the light-curing material into the 2 container tank, the second step is to input the first layer of the three-dimensional shape to be printed into the 1 development module through the computer, and the third step is to adjust the 3 through 4 screws according to the required printing thickness. The position of the working platform, the fourth step is to project the light emitted by the 6 light sources under the 1 developing module to the 1 developing module, and then the light passes through the 1 developing module and irradiates the light-curing material. The light-curing material is exposed to light From liquid to solid, the fifth step repeats the second to fourth steps until the printed layer is manufactured, and a three-dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com