The punching and positioning device for the upper and lower rail brackets of the rotary tablet press and its components

A rotary tablet press, hole positioning technology, applied to positioning devices, drilling molds for workpieces, metal processing machinery parts, etc., can solve the uncoordinated assembly of upper and lower guide rail brackets, and cannot meet industrial production and maintenance, movement Track and design track deviation and other issues, to achieve the effect of meeting industrial production and maintenance, coordinated combination and assembly, high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

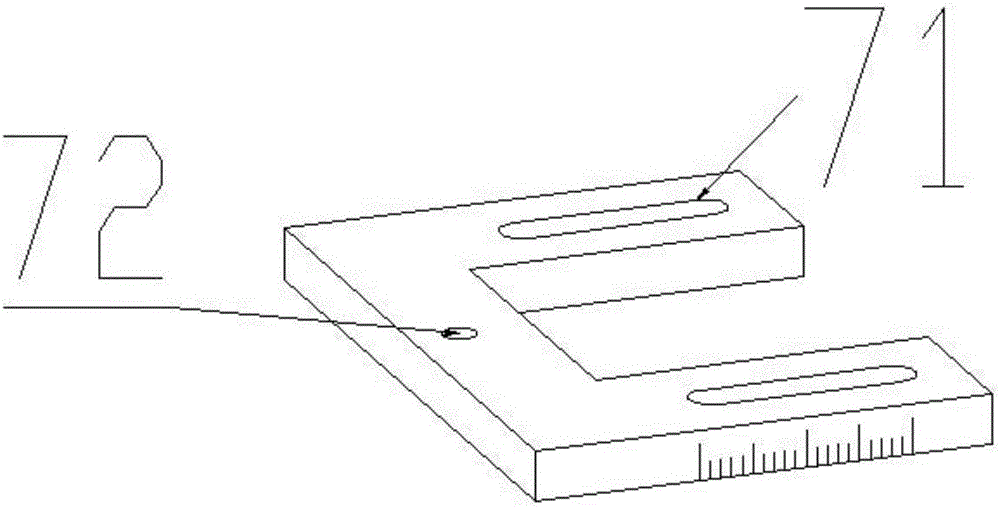

[0049] This embodiment provides a punching and positioning device for the upper and lower guide rail brackets of a rotary tablet press and its components, including: a base 1, a turntable 2, an upper guide rail bracket 3, a lower guide rail bracket 4, an upper guide rail bracket positioning boss 24, a lower guide rail Support positioning boss 25, component positioning boss 27, positioning plate 7, positioning pressure plate 8, pressure plate device 9.

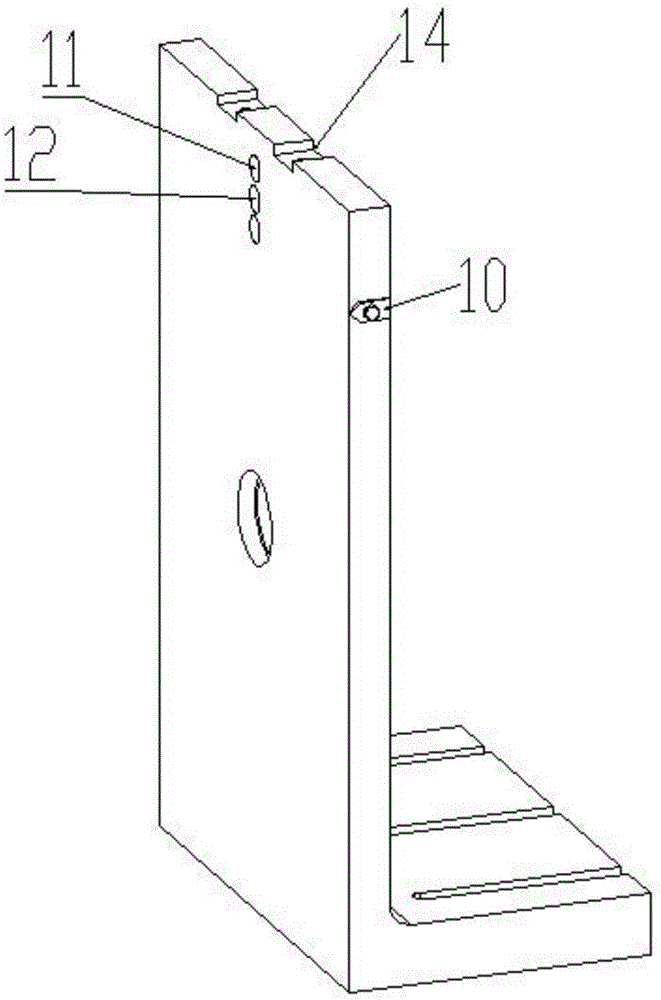

[0050] Such as figure 1 As shown, the base 1 is provided with a vertical mounting surface, and the mounting surface is provided with an upper rail positioning hole 11, a lower rail positioning hole 12, and a reference hole, and the upper rail positioning hole 11, the lower rail positioning Hole 12 and the reference hole are located on the same straight line along the vertical direction;

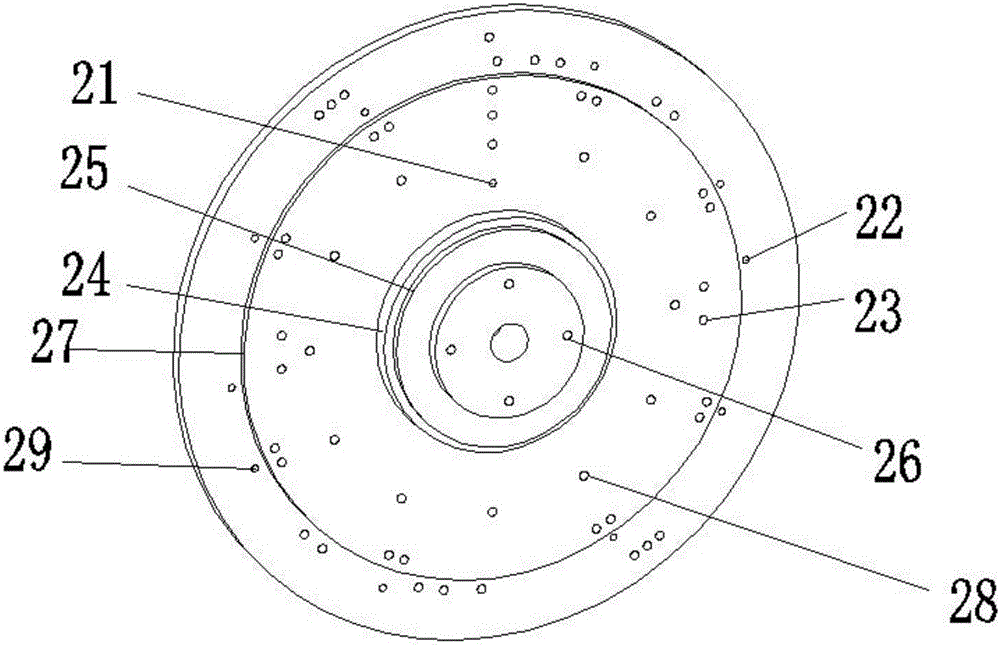

[0051] Such as Figure 13 As shown, the turntable 2 is installed vertically on the installation surface, and the spindle 5 is passed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com