Method for improving coiling temperature control accuracy of hot rolled new-variety new-specification band steel

A technology of coiling temperature and control accuracy, applied in the field of control, can solve problems such as low hit rate of first production accuracy and out-of-tolerance coiling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

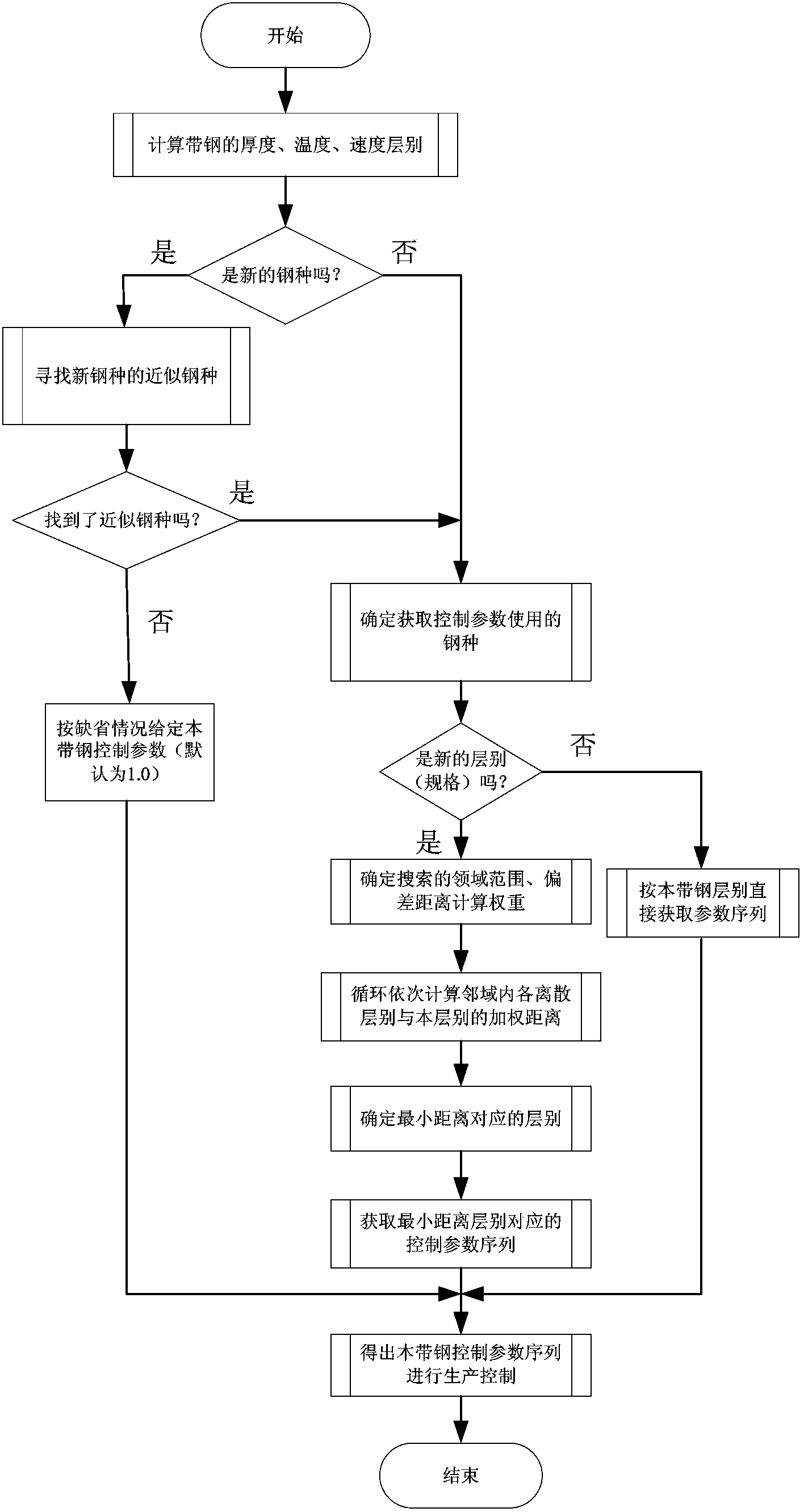

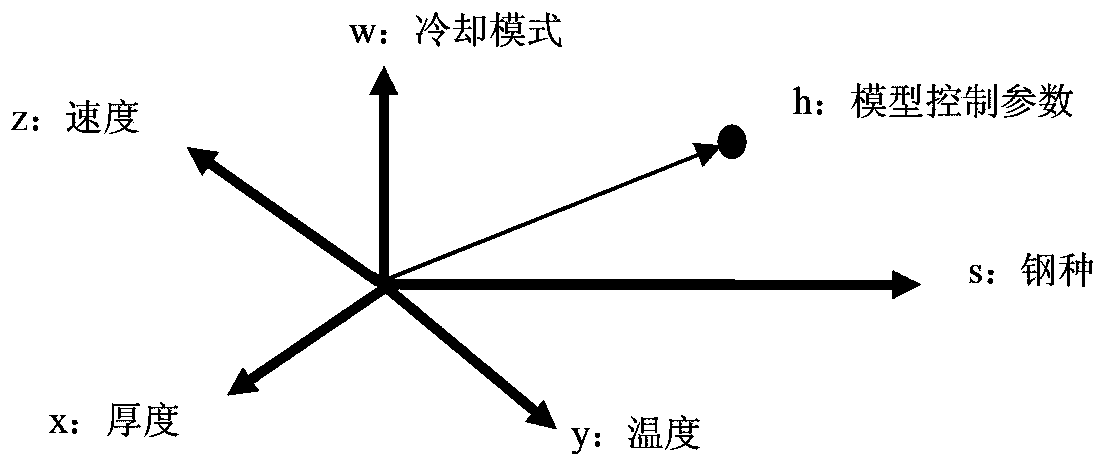

Method used

Image

Examples

Embodiment 1

[0129] Example 1: Control example of existing varieties but new specifications

[0130] Incoming materials:

[0131] c steel type: AQ3440E1;

[0132] ●The target coiling temperature is 560℃, and the corresponding temperature layer in this system is 4;

[0133] ●The target thickness is 2.62mm, and the corresponding thickness layer in this system is 9;

[0134] ●The target speed is 10.5m / s, and the corresponding thickness layer in this system is 40;

[0135] ●Cooling mode is "1";

[0136] When the coiling temperature control model determines the control parameters of the strip, it is found that the steel type, temperature layer, speed layer and cooling mode corresponding to the strip have actual production records in the system, but there is no thickness layer in the historical data. 9, so it is judged to be a new specification of an existing variety, and if it is, it automatically enters the control link of this method to search for the best match.

[0137] According to 4....

Embodiment 2

[0149] Embodiment 2: New Variety Control Example

[0150] Incoming materials:

[0151] ●Steel type: AP1056E1;

[0152] ●The target coiling temperature is 560℃, and the corresponding temperature layer in this system is 4;

[0153] ●The target thickness is 2.62mm, and the corresponding thickness layer in this system is 9;

[0154] ●The target speed is 10.5m / s, and the corresponding thickness layer in this system is 40;

[0155] ●Cooling mode is "1";

[0156] When the coiling temperature control model determines the control parameters of the strip steel, it is found that the steel type "AP1056E1" corresponding to the strip steel has no actual production performance in the system, so it is judged as a new variety, and if it is automatically entered into the above link of this method, the final best match search.

[0157] Step 1: Search for the steel type closest to AP1056E1 in the system (see the above description for the specific method), assuming that the found steel type i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com