Electric actuator torque protection device

An electric actuator and protection device technology, applied in emergency protection circuit devices, transmission devices, friction transmission devices, etc., can solve the problems of inaccurate slider movement, inaccurate force transmission, and inability to meet the needs of The effect of production, stable operation and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

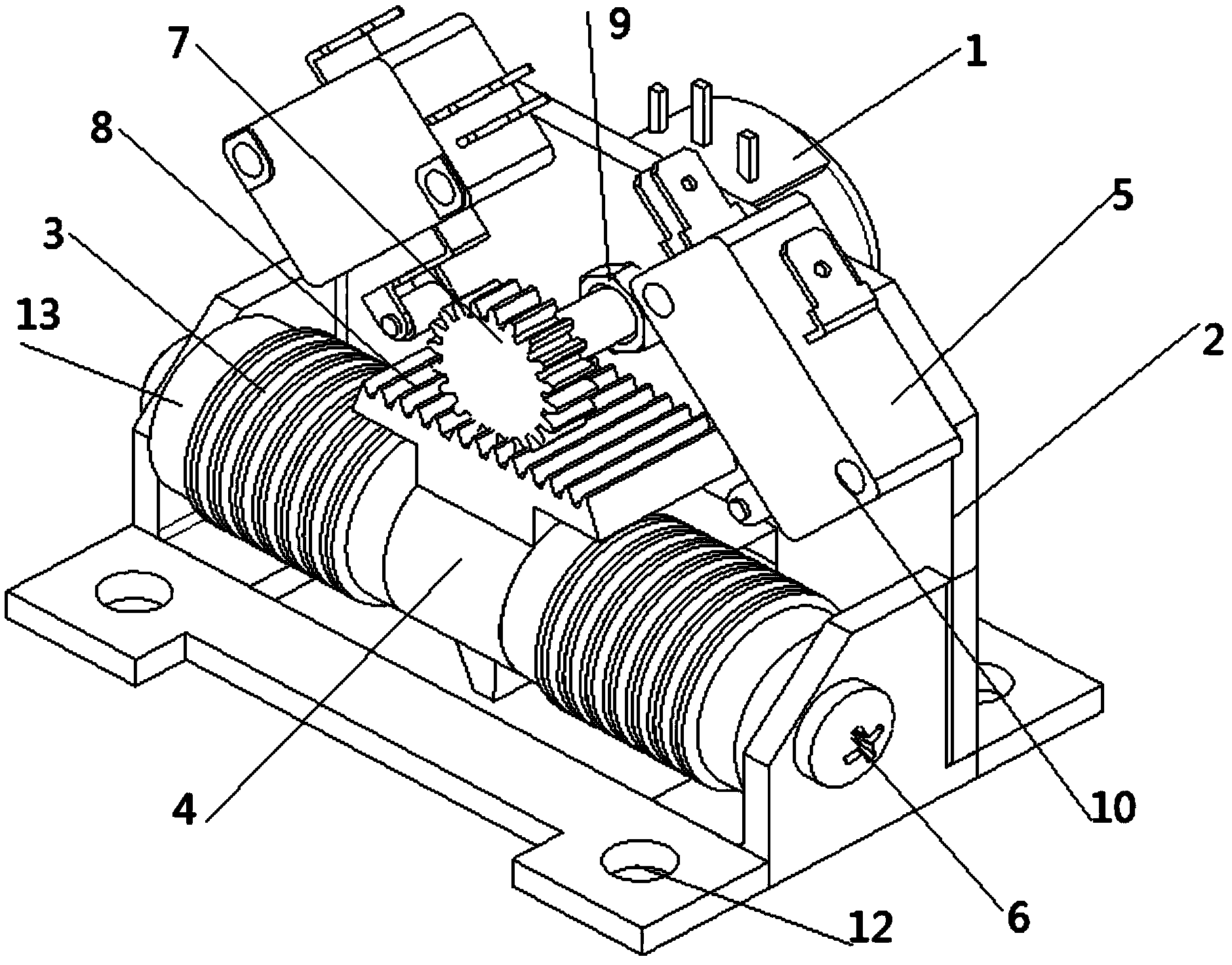

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

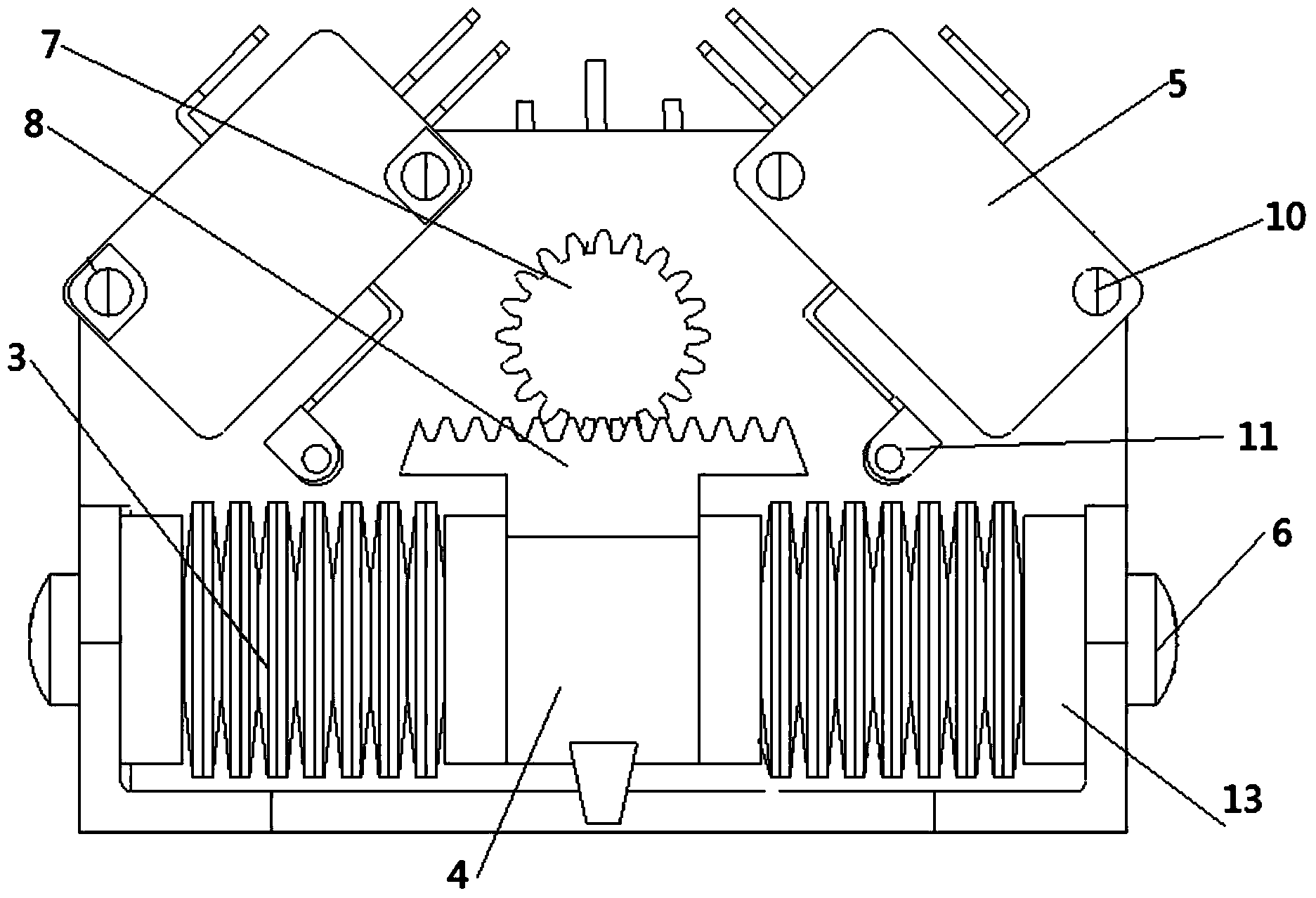

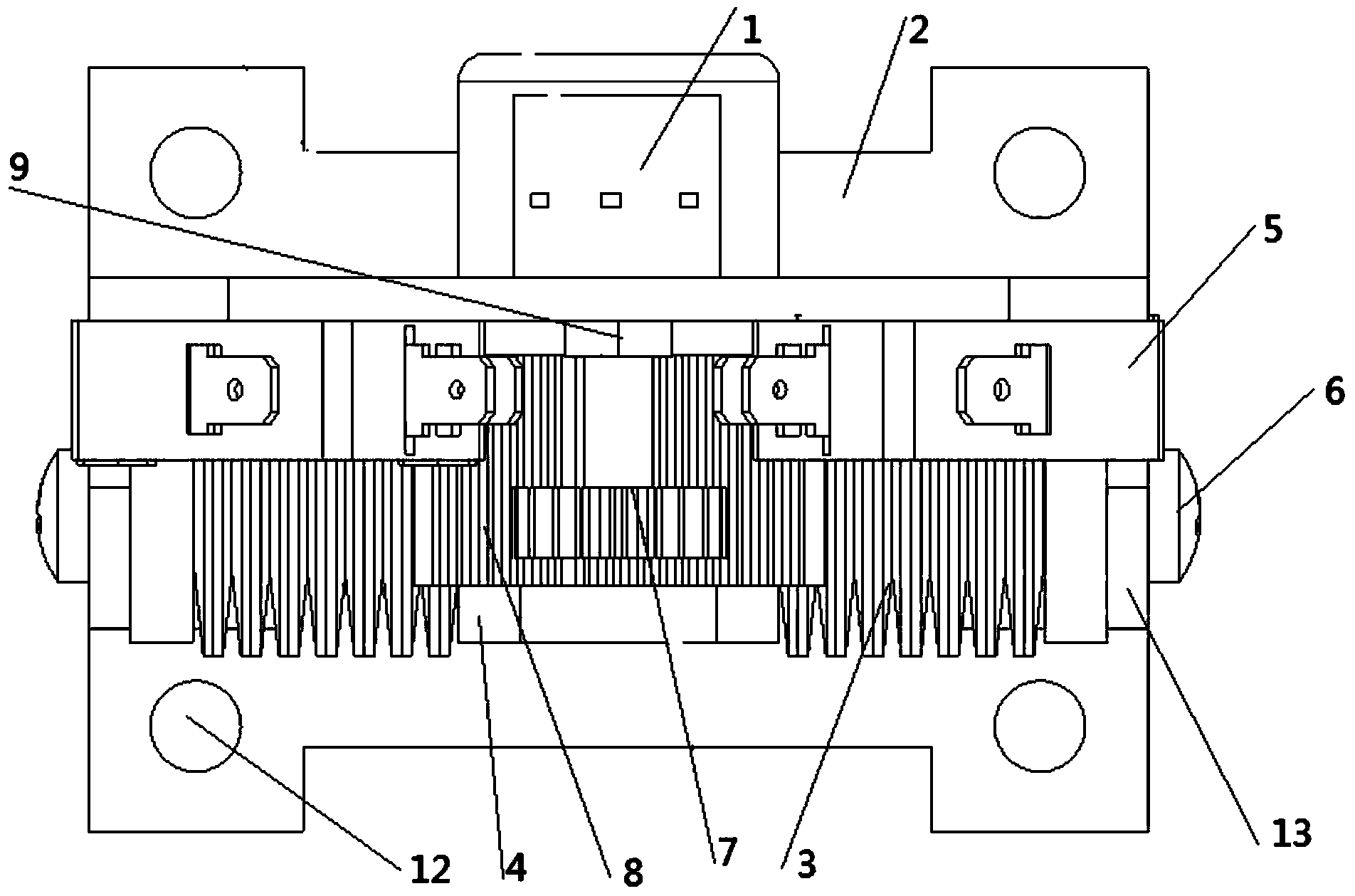

[0016] Such as figure 1 , figure 2 with image 3 The shown torque protection device for an electric actuator includes a frame 2 , a butterfly spring 3 and a gear 7 . The frame 2 includes a bottom plate, a vertical plate and two side plates. The frame 2 is used to set other equipment for the torque protection device of the entire electric actuator. There are threaded holes 12 on the four corners of the bottom plate. The threaded holes 12 are used for Fix the entire device in some other working position. Side plates are respectively arranged on both sides of the bottom plate, and guide rods 13 are also fixedly arranged on the side plates. The guide rod 13 and the side plate are fixed together by screws 6 , and two butterfly springs 3 are also arranged on the guide rod 13 . The two butterfly springs 3 are separated by the connecting block 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com