Terminal cell structure and manufacturing method using metal extension, polycrystalline stop field plate

A metal field plate and terminal unit technology, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve the problems of reducing the electric field and increasing the breakdown voltage, and achieves the reduction of the electric field, the reduction of the area, and the stability of the Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

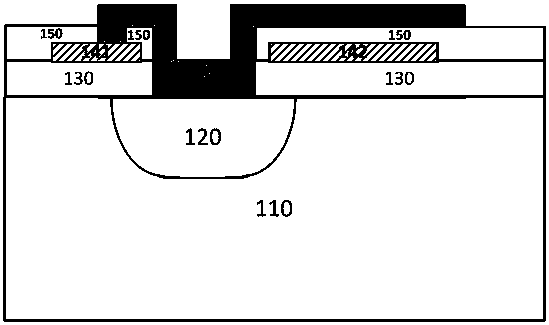

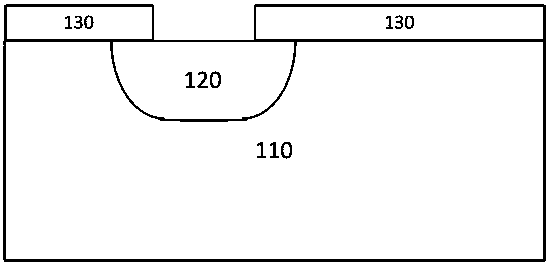

[0049] The terminal unit structure using metal extensions and polycrystalline stop field plates includes a substrate 110 of a first conductivity type, and a field limiting ring 120 of a second conductivity type is arranged in the first main surface of the substrate 110 of the first conductivity type. On the first main plane of the substrate 110 of the first conductivity type, a first insulating layer 130 is disposed; on the first insulating layer 130, a field plate is respectively disposed on both sides of the field limiting ring 120 of the second conductivity type The two field plates are provided with a second insulating layer 150, and the second insulating layer 150 is provided with a metal field plate 160; the bottom of the metal field plate 160 is in contact with the field limiting ring 120 of the second conductivity type, The metal field plate 160 covers the area of the field confinement ring 120 of the second conductivity type and its two sides; On the side, the field...

Embodiment 2

[0053] The terminal unit structure using metal extensions and polycrystalline stop field plates includes a substrate 110 of a first conductivity type, and a field limiting ring 120 of a second conductivity type is arranged in the first main surface of the substrate 110 of the first conductivity type. On the first main plane of the substrate 110 of the first conductivity type, a first insulating layer 130 is disposed; on the first insulating layer 130, a field plate is respectively disposed on both sides of the field limiting ring 120 of the second conductivity type The two field plates are provided with a second insulating layer 150, and the second insulating layer 150 is provided with a metal field plate 160; the bottom of the metal field plate 160 is in contact with the field limiting ring 120 of the second conductivity type, The metal field plate 160 covers the area of the field confinement ring 120 of the second conductivity type and its two sides.

[0054] The two field...

Embodiment 3

[0067] The terminal unit structure using metal extensions and polycrystalline stop field plates includes a substrate 110 of a first conductivity type, and a field limiting ring 120 of a second conductivity type is arranged in the first main surface of the substrate 110 of the first conductivity type. On the first main plane of the substrate 110 of the first conductivity type, a first insulating layer 130 is disposed; on the first insulating layer 130, a field plate is respectively disposed on both sides of the field limiting ring 120 of the second conductivity type The two field plates are provided with a second insulating layer 150, and the second insulating layer 150 is provided with a metal field plate 160; the bottom of the metal field plate 160 is in contact with the field limiting ring 120 of the second conductivity type, The metal field plate 160 covers the area of the field confinement ring 120 of the second conductivity type and its two sides.

[0068] The two field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com