Scissor-type high-voltage isolating switch assembly tooling

A high-voltage isolating switch and assembly tooling technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of difficult assembly requirements, low efficiency, and no high-voltage switch assembly tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

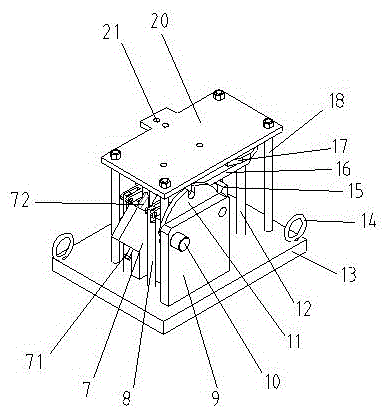

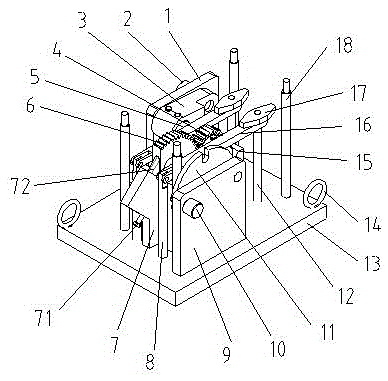

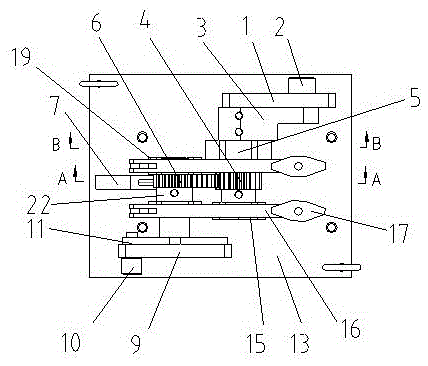

[0021] The embodiment of the scissors type high voltage isolating switch assembly tooling of the present invention, as Figure 1-9 As shown: it includes a base 13, a crank arm positioning plate 1 positioned on the rear side of the base 13 to locate the installation angle of the crank arm 3, and two pairs of drive shafts 5 are provided at intervals in the front and rear directions of the crank arm positioning plate 1 for support The effective V-shaped positioning block 15 is located in the front and rear direction of the left side of the V-shaped positioning block 15, corresponding to the two V-shaped positioning blocks 19 supported on the base 13 to the input shaft 22, and is located in the front and rear direction of the right side of the V-shaped positioning block 15. Two platen support screw rods 12 are provided, and two platen support rods 8 are arranged on the left side of the V-shaped positioning block 19. The front side of the V-shaped positioning block 19 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com