A Fatigue Evaluation Method and System for Nuclear Power Plant Pipeline Thermal Delamination Effect

A technology of fatigue evaluation and thermal stratification, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as high technical difficulty, large resource consumption, and inaccurate evaluation results, so as to reduce technical difficulty and save The effect of resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

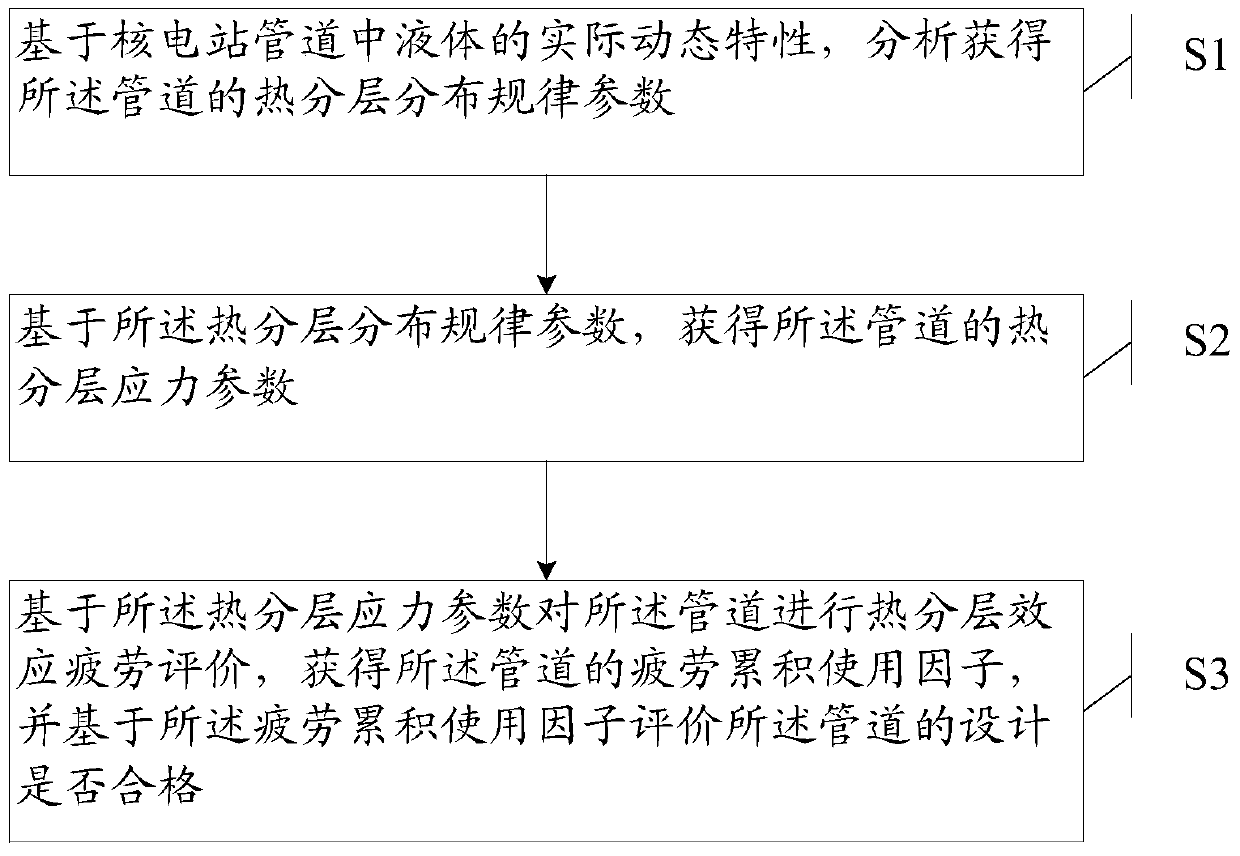

[0068] The embodiment of this application provides a fatigue evaluation method for thermal delamination effect of nuclear power plant pipelines, please refer to figure 2 , the method comprises the steps of:

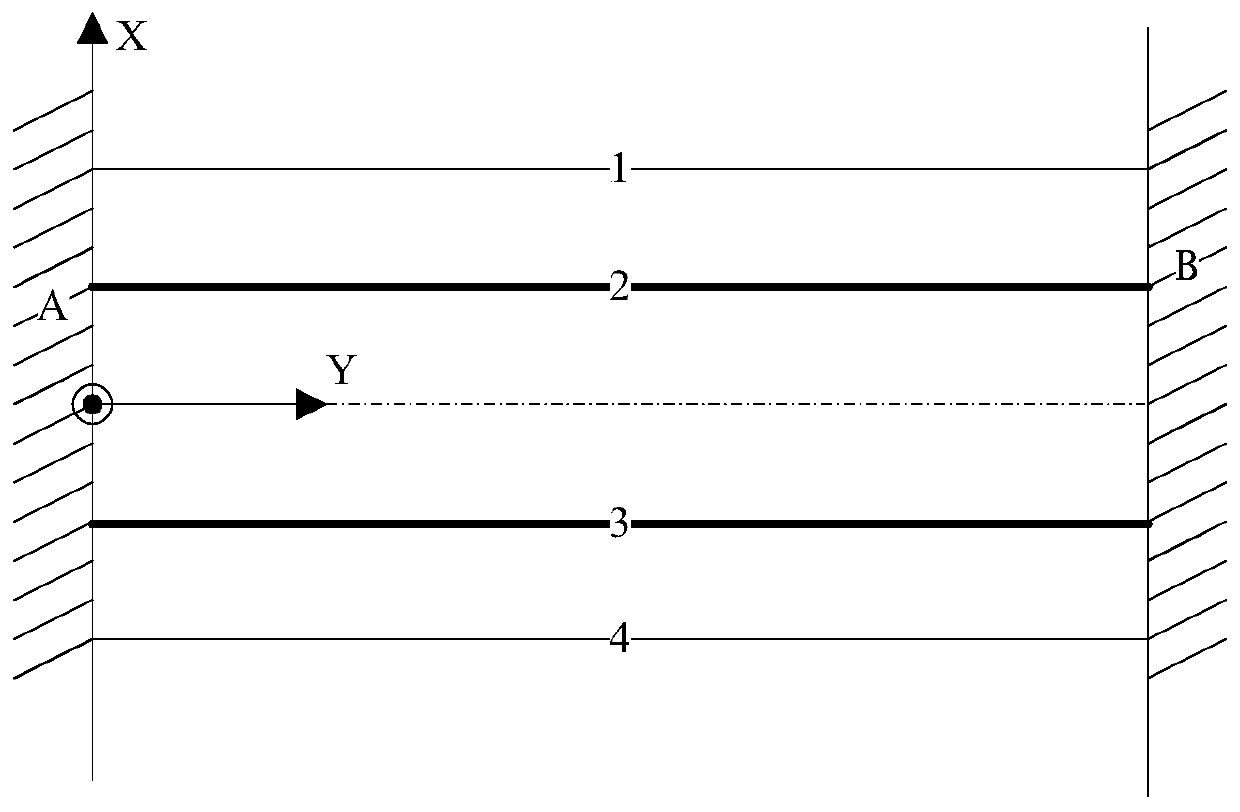

[0069] S1. Based on the actual dynamic characteristics of the liquid in the pipeline of the nuclear power plant, analyze and obtain the parameters of the thermal stratification distribution law of the pipeline;

[0070] S2. Obtain a thermal delamination stress parameter of the pipeline based on the thermal delamination distribution rule parameter;

[0071] S3. Perform thermal delamination effect fatigue evaluation on the pipeline based on the thermal delamination stress parameters, obtain a fatigue cumulative use factor of the pipeline, and evaluate whether the design of the pipeline is qualified based on the fatigue cumulative use factor.

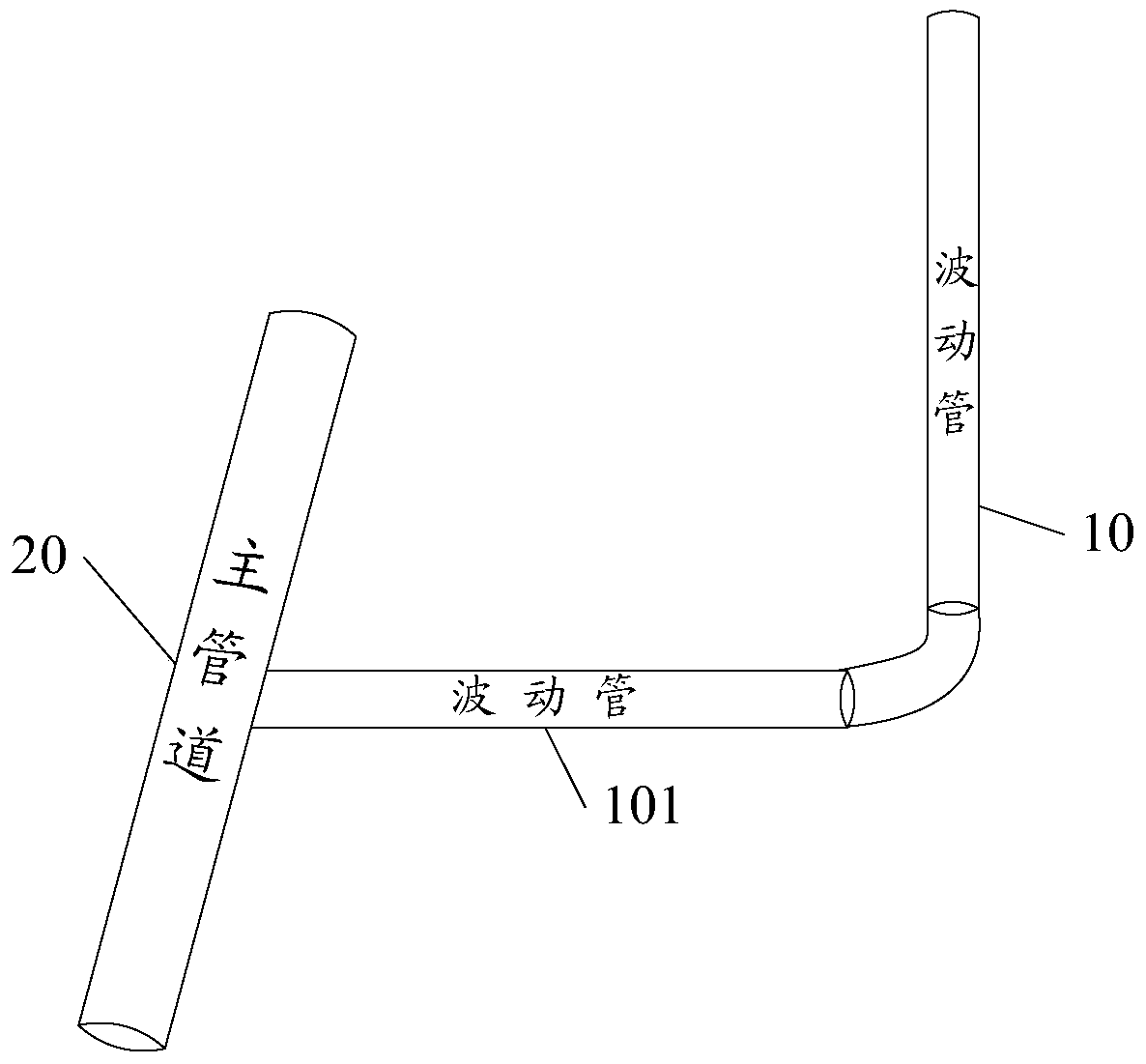

[0072] Taking the wave pipe and main pipe of the pressurized water reactor nuclear power plant in service as an example, first of ...

Embodiment 2

[0118] Based on the same inventive concept, the embodiment of this application also provides a fatigue evaluation system for thermal delamination effect of nuclear power plant pipelines, please refer to Figure 9 , where the system includes:

[0119] The thermal stratification distribution rule parameter acquisition unit 901 is used to analyze and obtain the thermal stratification distribution rule parameter of the pipeline based on the actual dynamic characteristics of the liquid in the pipeline of the nuclear power plant;

[0120] A thermal delamination stress parameter acquisition unit 902, configured to obtain a thermal delamination stress parameter of the pipeline based on the thermal delamination distribution rule parameter;

[0121] The fatigue evaluation unit 903 is configured to perform thermal delamination effect fatigue evaluation on the pipeline based on the thermal delamination stress parameters, obtain the fatigue cumulative use factor of the pipeline, and evalua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com