A mobile high-temperature smoke and dust waste gas flow field control device and process method

A field-controlled, mobile technology, applied in the acid field, can solve the problems of increasing exhaust volume, low operating cost, escape of smoke and exhaust gas, etc., and achieve the effect of reducing air intake, energy saving and emission reduction, and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

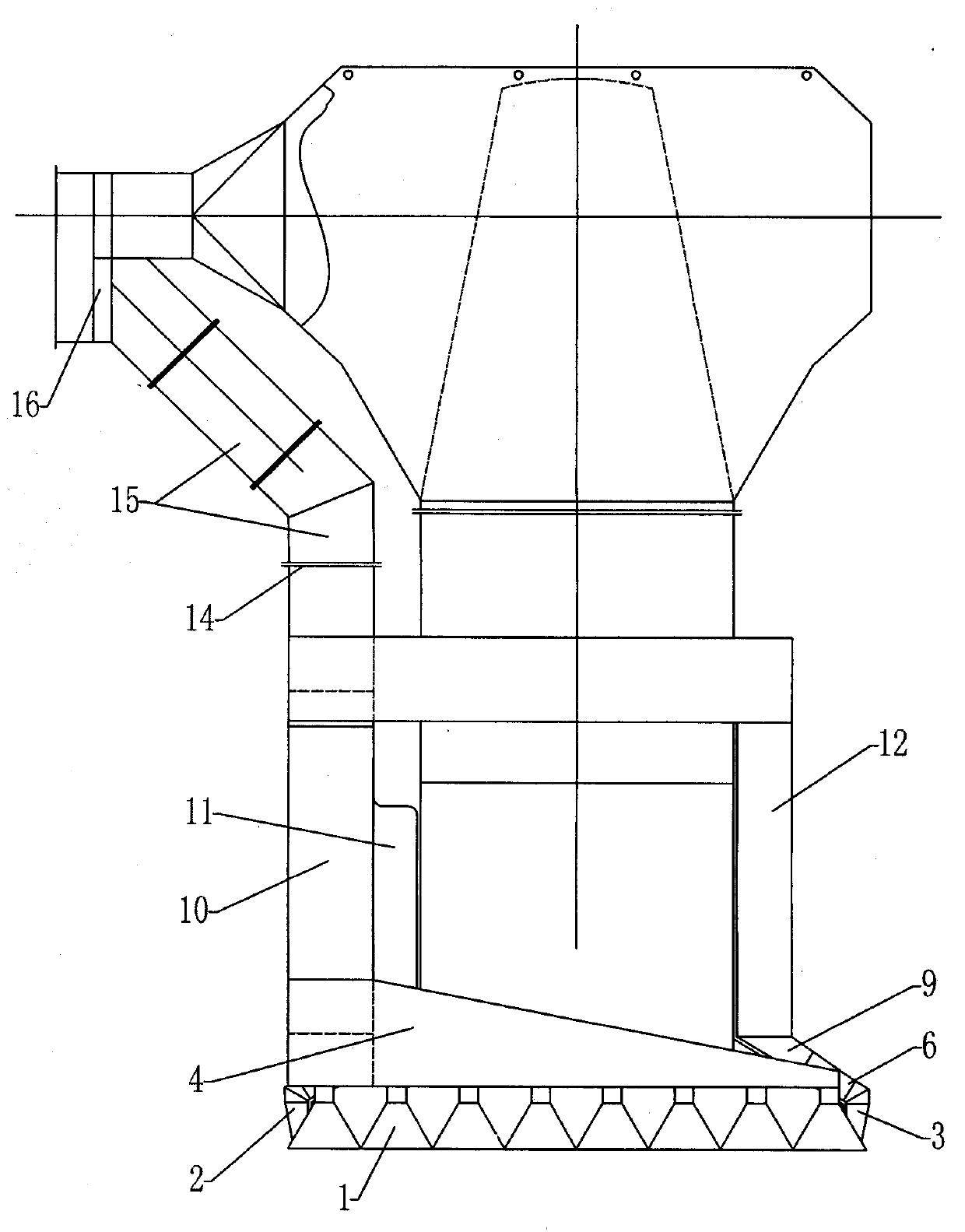

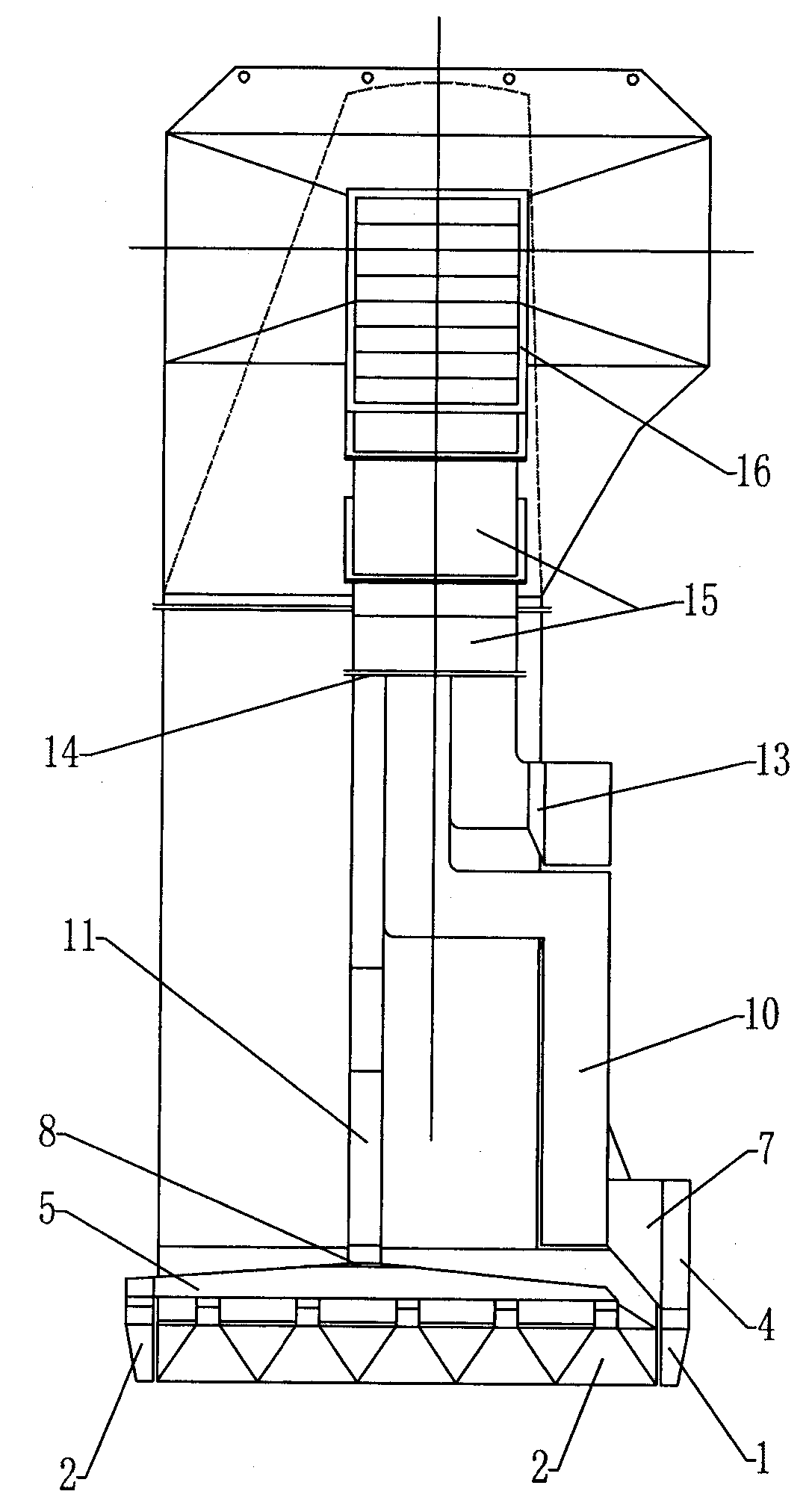

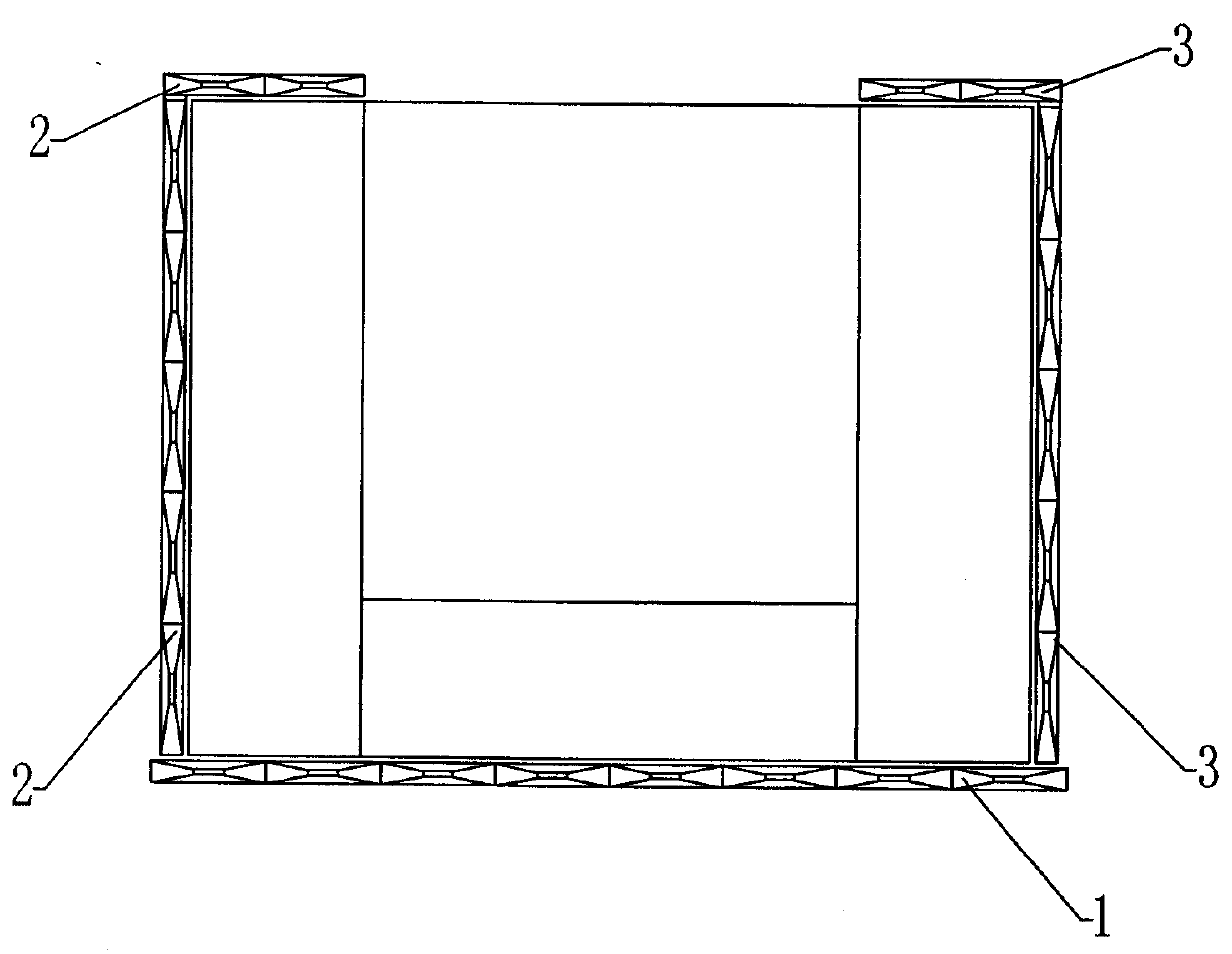

[0023] The mobile high-temperature smoke and dust waste gas flow field control device and the process method of the present invention are realized in this way, which will be described in detail below in conjunction with the accompanying drawings.

[0024] See Figure 1 to Figure 4 , the mobile high-temperature smoke and dust exhaust flow field control device is a cover structure, which is composed of a flow field drive system and a thermal energy diversion system. The flow field drive system consists of: front drive device, left drive device, right drive device, and three-channel connection method Lan 14, pipeline system distribution negative pressure device 15, smoke and dust waste gas negative pressure drainage section 16, connecting pipe sections and pipe fittings.

[0025]The front drive device is composed of a front seam cover group 1, a front cover group collecting pipe 4, a front cover group pipe fitting 7 and a front cover group collecting pipe connecting pipe 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com