Current transformer based on magnetically controlled grating light valve and method for detecting bus current

A technology of current transformer and grating light valve, which is used in the measurement of current/voltage, voltage/current isolation, instruments, etc., can solve the problems of high machining process requirements, difficult to improve accuracy, difficult to large-scale application, etc. Energy supply cost, lower insulation design cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

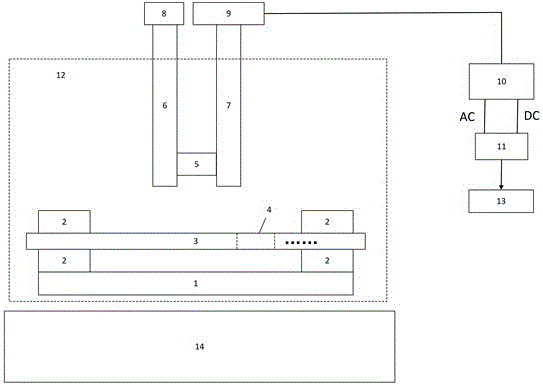

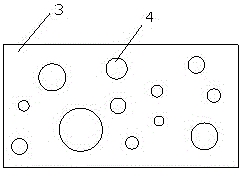

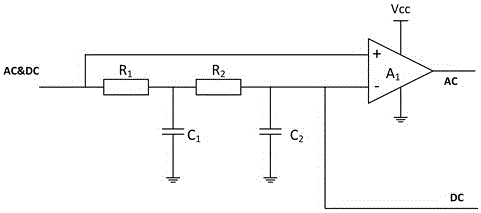

[0029] like figure 1 As shown, a current transformer based on a magnetically controlled grating light valve of the present invention includes a high-voltage bus 14, a light source 8, a magnetically controlled grating light valve 12, a photoelectric receiver 9, an AC / DC separation module 10, a divider 11 and The output voltage value is 13. The AC / DC separation module 10 is an AC / DC separation module. The output end of the light source 8 is connected to the input end of the magnetically controlled grating light valve 12, the output end of the magnetically controlled grating light valve 12 is connected to the input end of the photoelectric receiver 9, and the output end of the photoelectric receiver 9 is connected to the AC / DC separation module 10 The input end of the AC / DC separation module 10 is connected to the input end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com