Voltage and current combined sensor and voltage and current detection system

A voltage, current, and voltage detection technology, applied in the electric power field, can solve the problems of high insulation design cost, poor safety, and high insulation performance requirements of transformers, and achieve the effect of reducing insulation design cost and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

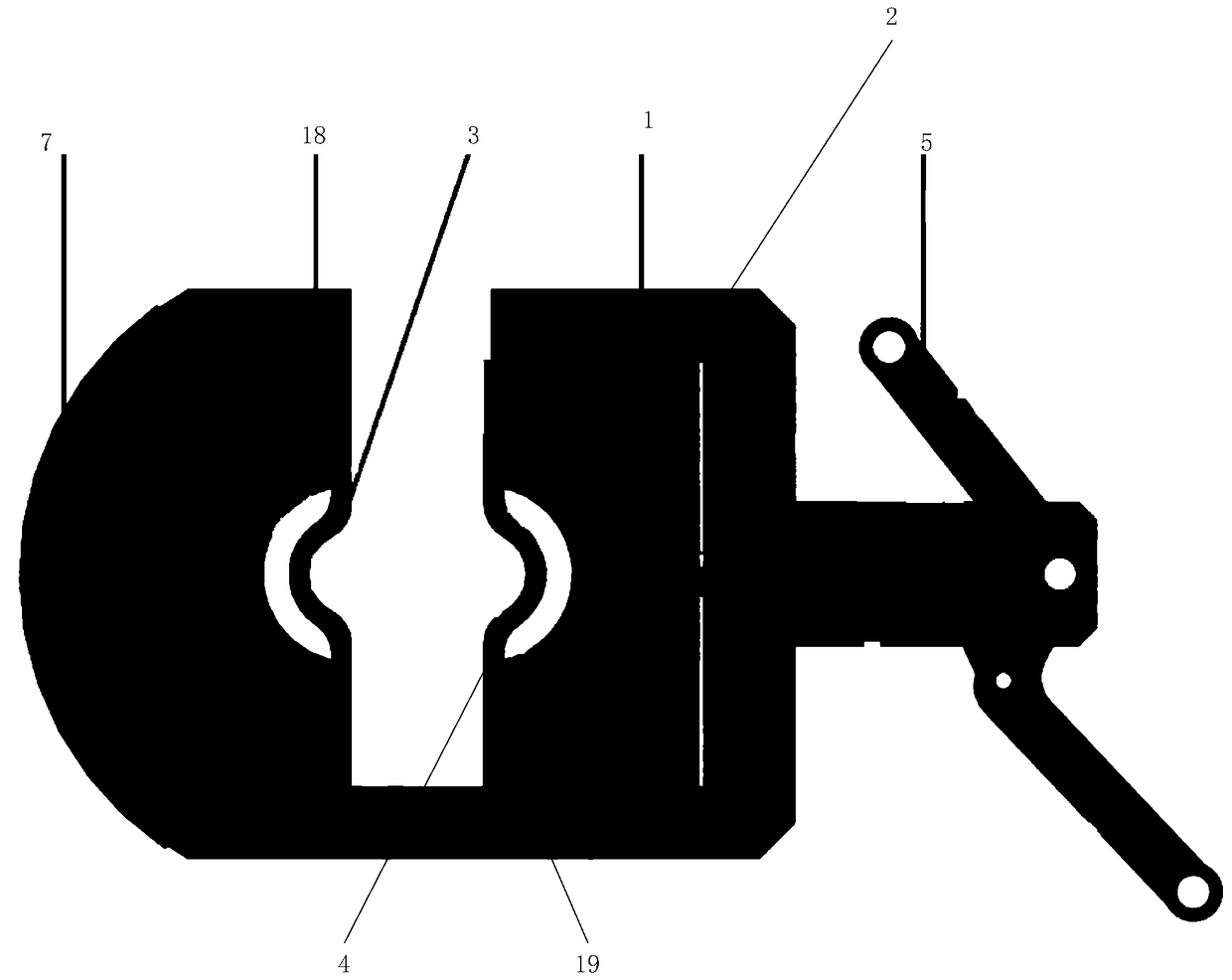

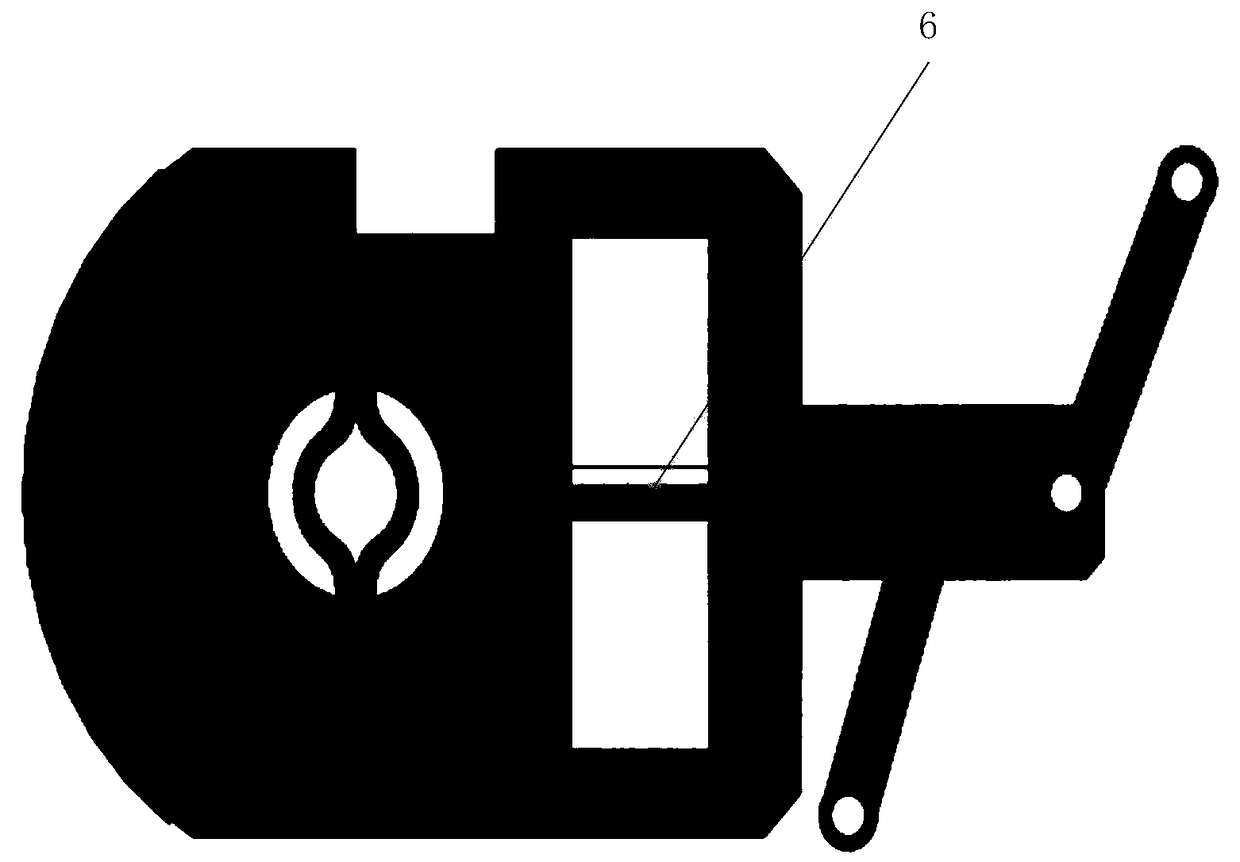

[0050] In this embodiment, a combined voltage and current sensor is shown, please refer to Figure 1 to Figure 5 , The voltage and current combined sensor includes: a fixed bracket 1, a movable bracket 2, a first wire fixing mechanism 3 and a second wire fixing mechanism 4, a locking handle 5, a linkage mechanism 6, an electric field sensor probe 7 and a magnetic field sensor probe.

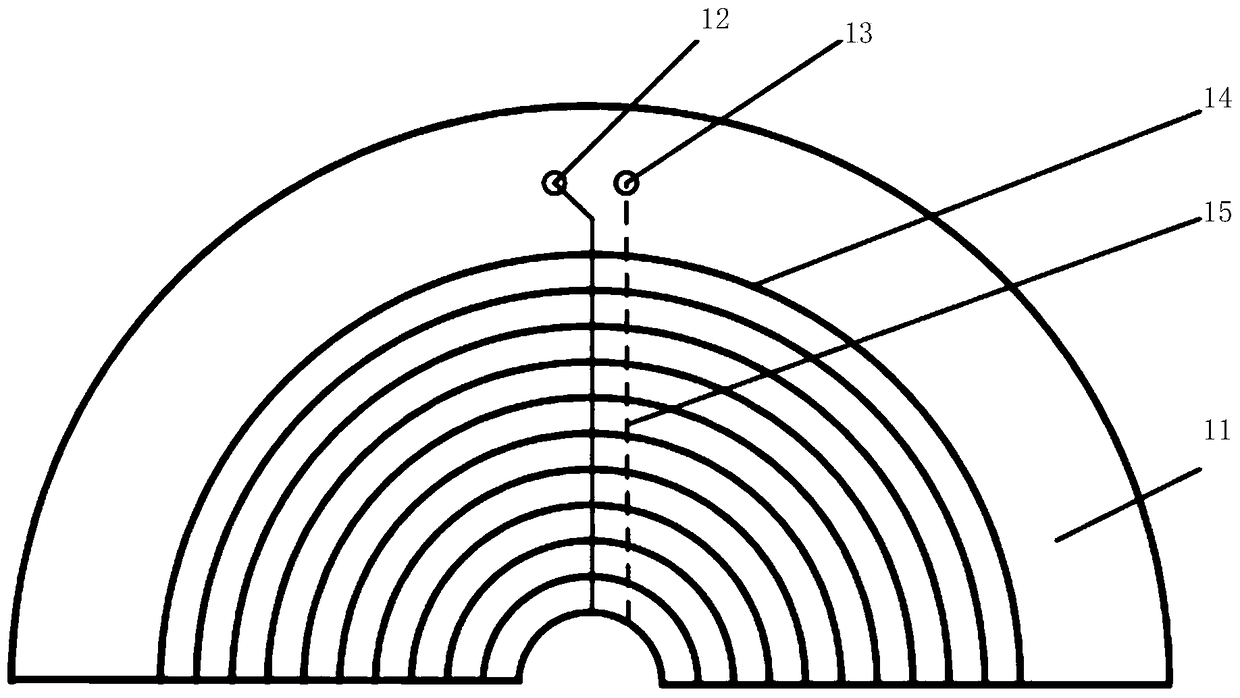

[0051] The electric field sensor probe 7 includes: a PCB substrate 11, a first electrode group, a second electrode group, a first terminal 12 and a second terminal 13, and the first electrode group includes a plurality of serially connected semi-annular structures. The first electrode 14, and the second electrode group includes a plurality of second electrodes 15 in a semi-circular structure connected in series.

[0052] The magnetic field sensor probe includes a first iron core 18, a second iron core 19, a Rogowski coil, a third terminal and a fourth terminal;

[0053]The first iron core 18 is ...

Embodiment 2

[0068] In this embodiment, a voltage and current detection system is provided, please refer to Image 6 , The voltage and current detection system includes: a voltage detection device 61 , a current detection device 62 and a combined voltage and current sensor 63 .

[0069] For the specific structure and related functions of the combined voltage and current sensor 63 , please refer to the combined voltage and current sensor shown in Embodiment 1, which will not be repeated here.

[0070] The voltage detecting device 61 is connected to the combined voltage and current sensor 63 , and the current detecting device 62 is connected to the combined voltage and current sensor 63 .

[0071] The voltage detection device 61 is configured to process the potential difference signal output by the voltage-current combined sensor 63 to obtain the voltage of the transmission line to be detected.

[0072] The current detection device 62 is configured to process the induced electromotive force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com