Precise vertical type length gauge

A length meter, vertical technology, applied in the field of precision vertical length meter, can solve the problems of small measuring range, inability to take into account high precision and large range, narrow application range, etc., and achieve the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

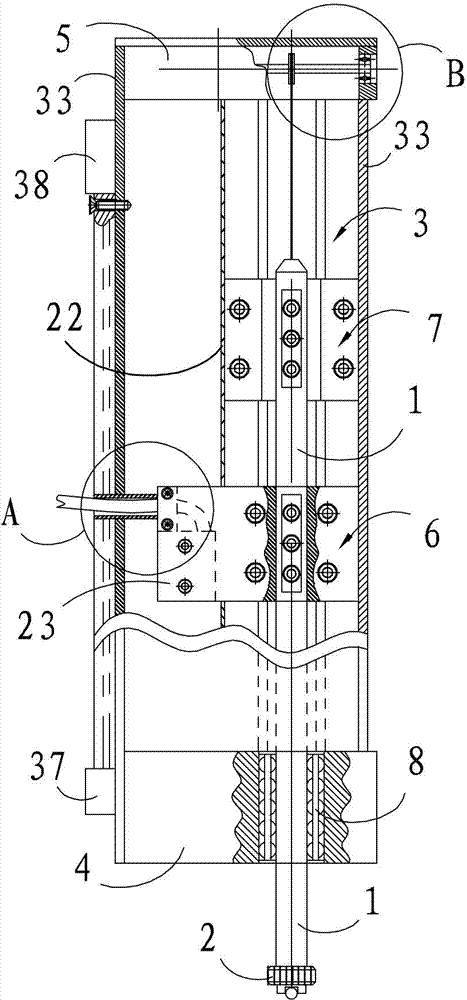

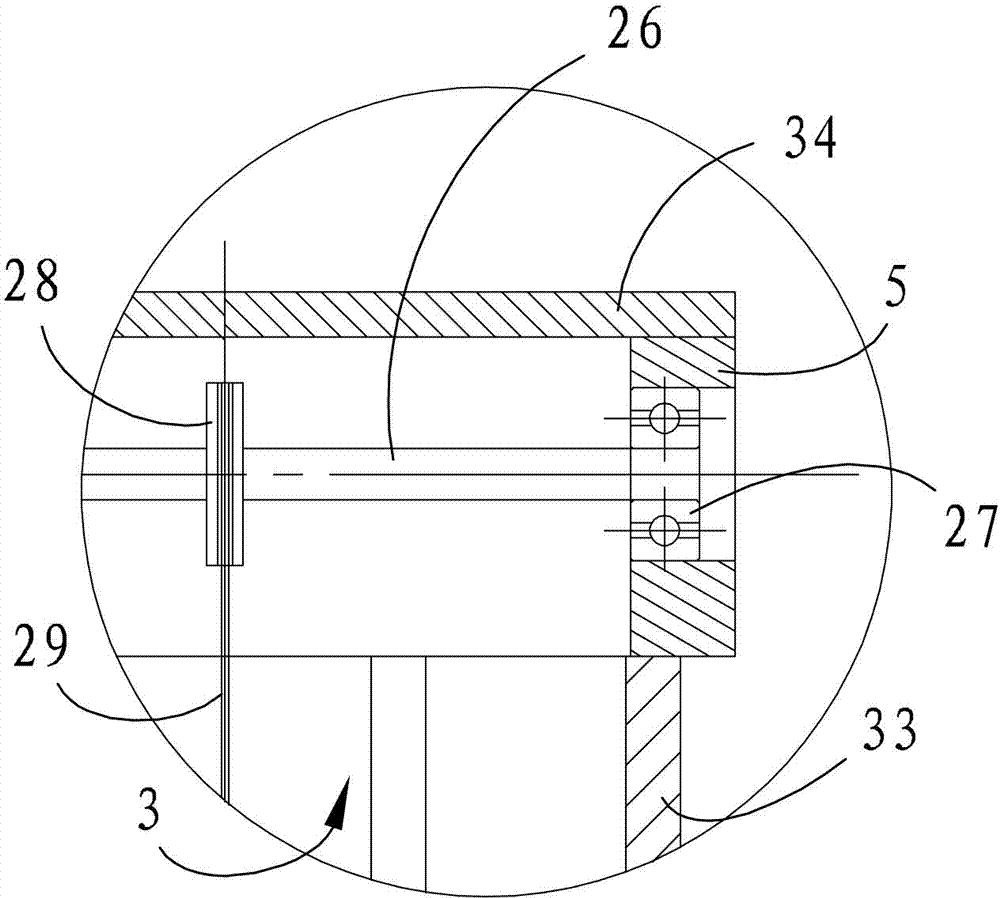

[0036] This embodiment relates to a precision vertical length gauge, such as Figure 1 to Figure 4 As shown in , it includes a measuring rod 1, and a probe frame 2 is connected to the bottom end of the measuring rod 1. The probe frame 2 can be threadedly connected with the measuring rod 1, and a probe is installed on the probe frame 2. The head can be a spherical head, or a knife-edge head, a flat head, a roller head, etc. This length gauge also includes a guide support mechanism that guides and supports the movement of the measuring rod 1. The guide support mechanism includes a linear guide rail 3, on which a first sliding assembly 6 and a second sliding assembly 7 are slidably arranged, and a linear bearing 8 is also connected to the bottom end of the linear guide rail 3, and the measuring rod 1 is slidingly sleeved. In the linear bearing 8 and connected to the first sliding assembly 6 and the second sliding assembly 7 on the linear guide rail 3 accordingly.

[0037] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com