Small mechanical part shape and position error detection device and detection method thereof

A technology for mechanical parts, shape and position error, applied in the field of mechanical parts shape and position error detection equipment, can solve the problems of expensive detection equipment, inability to achieve online detection, affecting the final accuracy of measurement results, etc., to improve detection accuracy and detection accuracy. , Improve detection efficiency and detection accuracy, and achieve the effect of automatic online detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

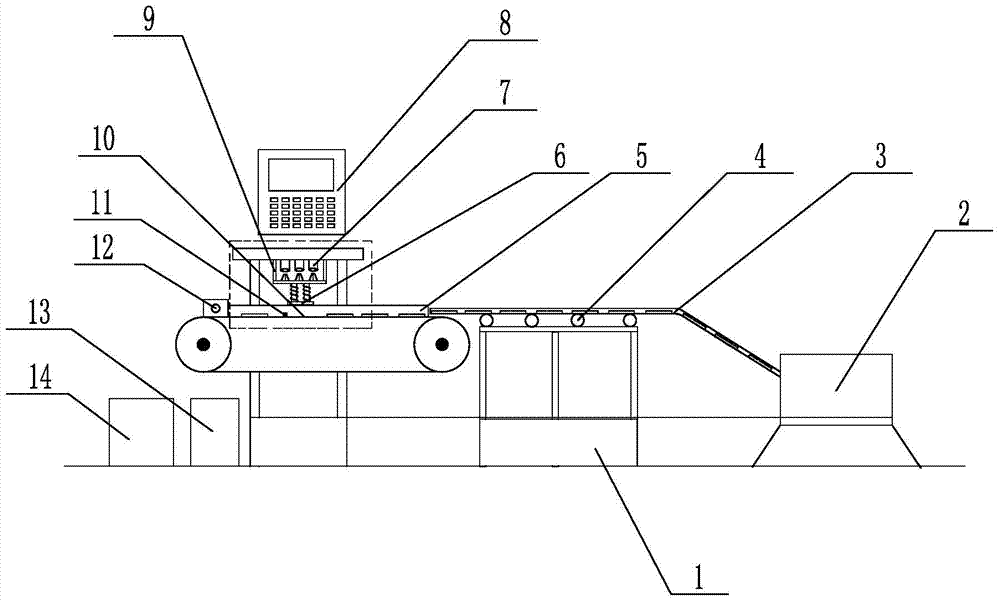

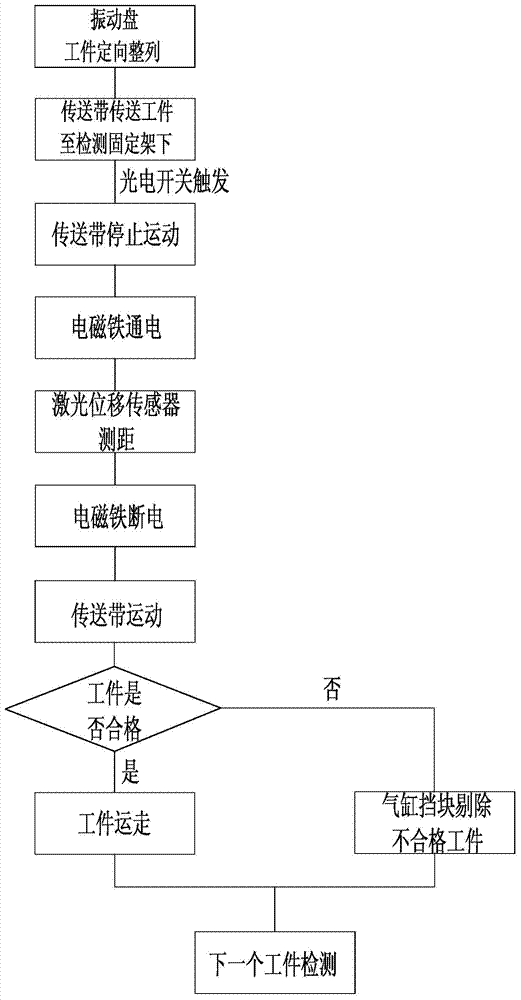

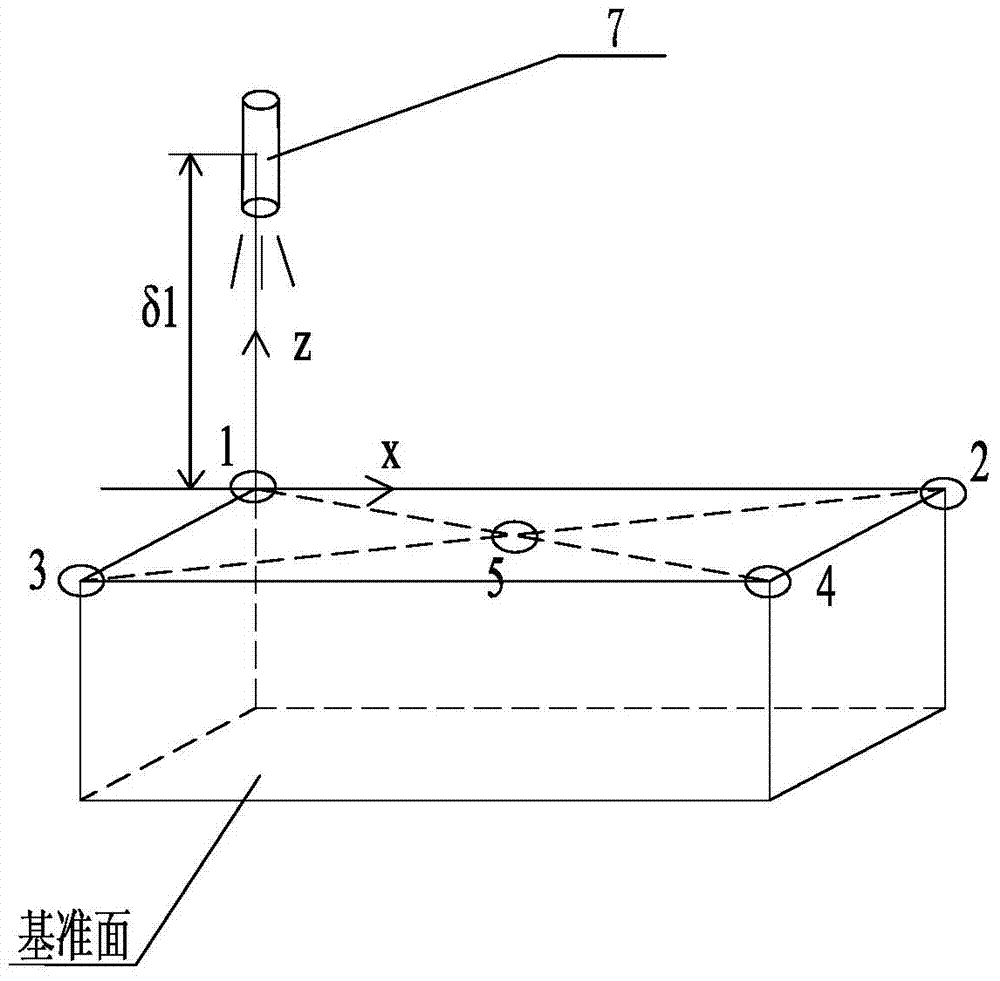

[0049] Such as figure 1 As shown, the shape error detection device for small mechanical parts of the present invention includes a base 1, a vibration plate 2 is installed on one end of the base 1, and the discharge port of the vibration plate 2 is connected to the feed end of the material channel 3 , the material channel 3 is supported by the material channel support rod 4 installed on the top of the middle position of the base 1, the discharge end of the material channel 3 corresponds to the feed end of the conveyor belt 10, and the two sides of the conveyor belt 10 are equipped with limit plates 5, The detection fixture 9 is installed on the top of the conveyor belt 10, and the detection fixture 9 is installed on the end of the base 1. The front, rear, left, right and top of the detection fixture 9 are equipped with laser displacement sensors 7, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com