Method for Improving Engine Efficiency and Engine Compatible with the Method

An engine and power technology, which is applied in the direction of combustion engines, machines/engines, mechanical equipment, etc., can solve the problems that the energy in the initial combustion period is not effectively used, the mass and size of the engine increase, and the service life of the engine is affected, so as to save fuel. Effect of reducing vibration and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

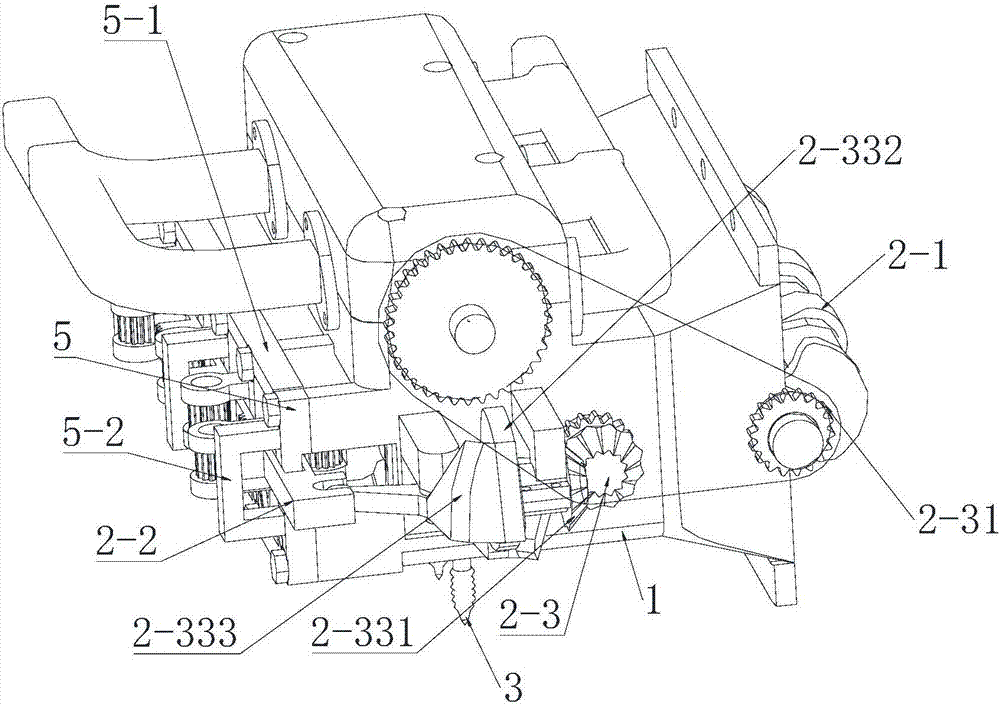

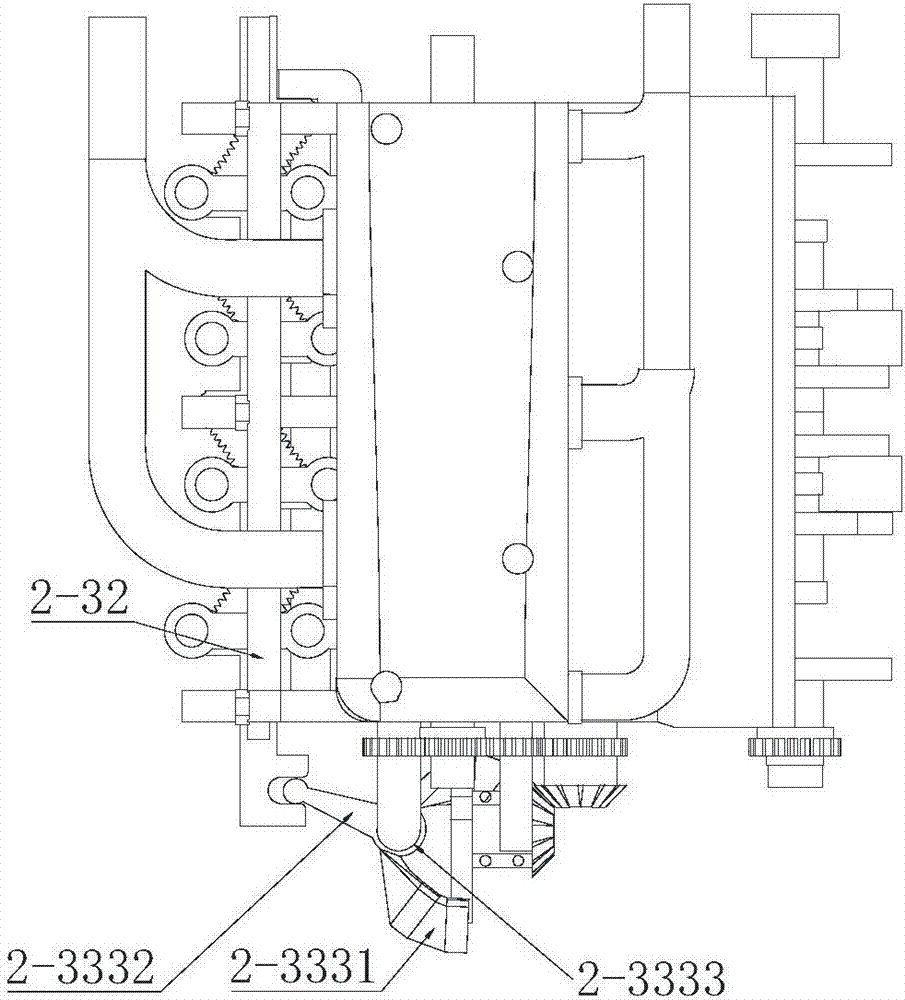

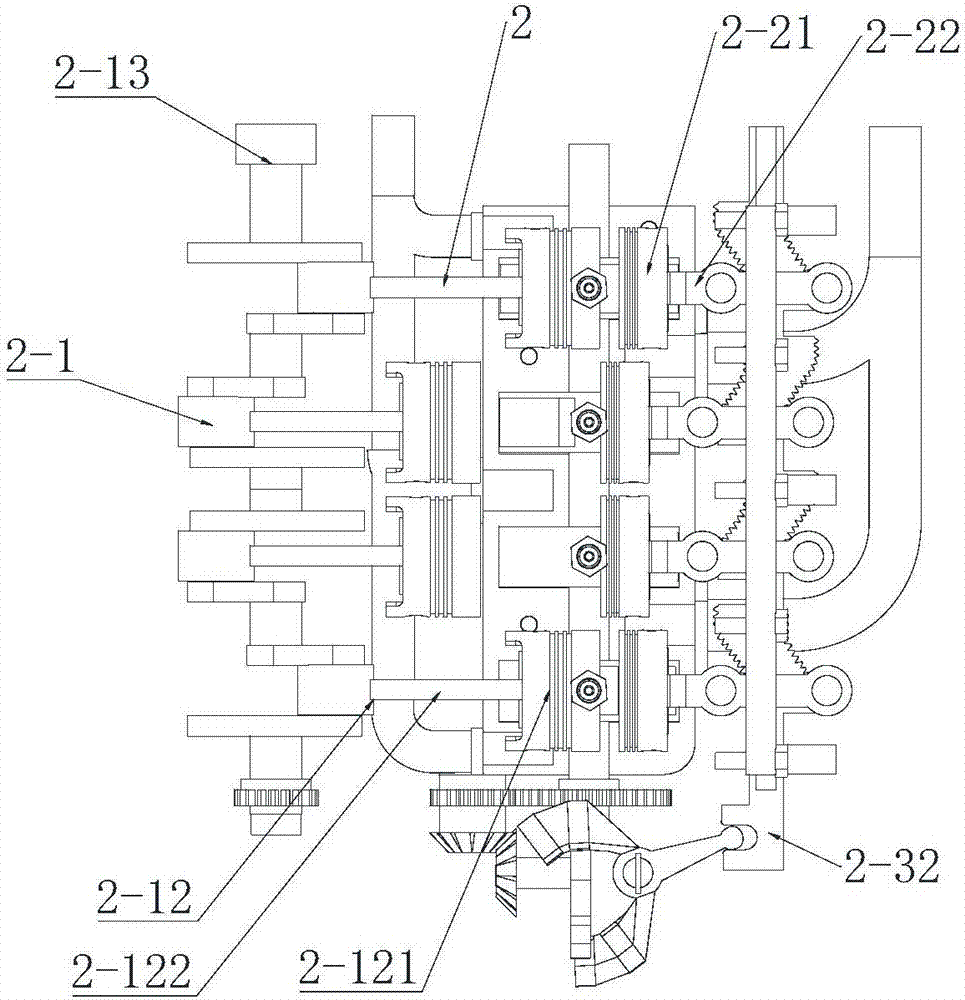

[0072] Such as Figure 1-Figure 10 As shown, the engine of the present invention adopts a four-cylinder structure, including an engine frame 1 and a power transmission system 2, a spark plug 3, a fuel injector and an intake and exhaust system 4 arranged on the engine frame 1, and the power transmission system 2 includes a The crank linkage mechanism 2-1 of the system and the power acceleration compensation device 2-2 corresponding to the crank linkage mechanism; the crank linkage mechanism 2-1 includes the body group 2-11, the piston connecting rod group 2-12 and the crankshaft flywheel group 2-13, the body group includes a crankcase 2-111, a cylinder block 2-112, and a cylinder head connected and matched with the cylinder block, and the piston connecting rod group 2-12 includes the main power piston 2-121 arranged in the cylinder body and the main power piston 2-121 connected with the main cylinder body. The active power piston connecting rod 2-122 that is movably connected t...

Embodiment 2

[0082] Such as Figure 12-Figure 16 As shown, this embodiment is different from the design of the swing follower cam mechanism in Embodiment 1. The swing follower cam mechanism 2-33 includes a rotating sleeve 2-334 driven by the output gear of the sprocket drive mechanism, a swing Rod 2 2-335, swing fulcrum 2 2-336 is arranged on the swing rod 2, one end of the swing rod 2 is movably connected with the rotating sleeve, and the other end is connected with the slide bar; The axis of 334 forms an annular groove 2-337 with a certain inclination angle, and one end of the swing rod 2 is provided with a sliding piece that is slidably connected with the annular groove. Through the rotation of the rotating sleeve, the sliding piece slides along the track of the annular groove, thereby The two pairs of slide bars are driven to push and pull the swing bar.

[0083] In this example, if Figure 19 As shown, in order to increase the stability of the rotating sleeve driven by the output ge...

Embodiment 3

[0085] Such as Figure 17 and Figure 18 As shown, this embodiment is different from the design of the intake and exhaust system of Embodiment 1. The intake and exhaust system 4 includes intake and exhaust passages 4-4 and 4-5 connected to the cylinder block. Valves 4-6 are respectively arranged in the gas channel, and return springs 4-7 are installed on the valves, and the end of the valves is connected with a cam mechanism 4-8, which is used to drive the opening or closing of the valves; the cam mechanism 4-8 includes a cam 4-81 And lever 4-82, one end of the lever and the terminal movable push-fit of valve, the axle of cam and crankshaft are linked by transmission mechanism, and the opening and closing of valve are driven by crankshaft, complete the intake and exhaust function of engine.

[0086] The invention greatly improves the existing engine technology, has low manufacturing cost, can optimize the material consumption of the existing engine, and adds a power accelerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com