Rabbit hair carding machine

A carding machine and rabbit hair technology, applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve problems such as unsatisfactory carding effect of thick and thin rabbit hair, interference of foreign objects, and complicated equipment mechanism, etc., to achieve deburring The effect of coarse and impurity removal is good, the effect of reducing flying catkins and optimizing the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

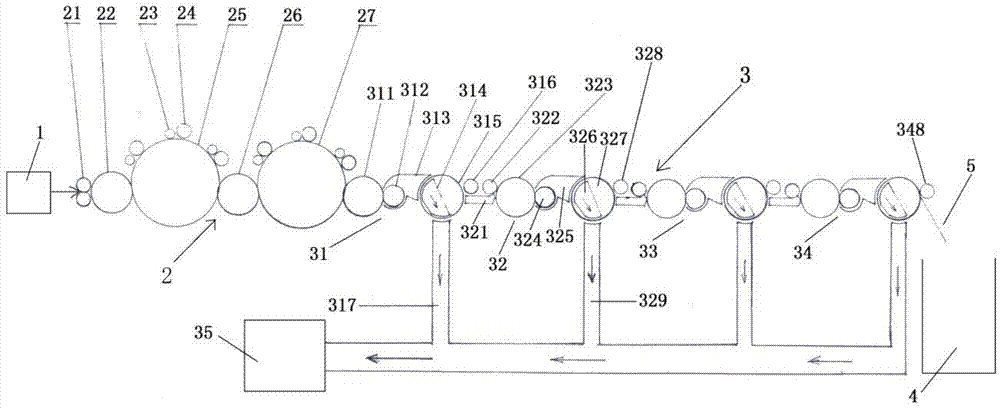

[0029] Embodiment 1 (see figure 1 )

[0030]Take the loosening and roughing part with 4 sets of loosening and roughing parts as an example. Feed the raw rabbit hair that has been loosened, humidified and veneered for more than 8 hours into the feeding part 1 of the carding machine, and the feeding part 1 sends the raw material evenly into the carding part 2.

[0031] In the carding part 2, the feeding roller 21 with a diameter of 85mm delivers the rabbit hair to the opening roller 22 that is wrapped with a metal saw blade at a speed of 56 revs / min at a speed of 56 revs / min for a diameter of 250 mm. The linear speed ratio of the hair-feeding roller 21 is about 4:1, and the hair-opening roller 22 pulls the rabbit hair out from the hair-feeding roller 21, so the rabbit hair is opened. Because most thick rabbit hairs are straighter and less curly than fine rabbit hairs, and most thick rabbit hairs are longer and heavier than fine rabbit hairs (for example: fine hairs, the averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com