Rolling cutter assembly

A technology of rolling knives and components, which is applied to flange-type bottle caps and other directions, can solve the problems such as the inability to adjust the rolling knives, and achieve the effect of simple structure and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

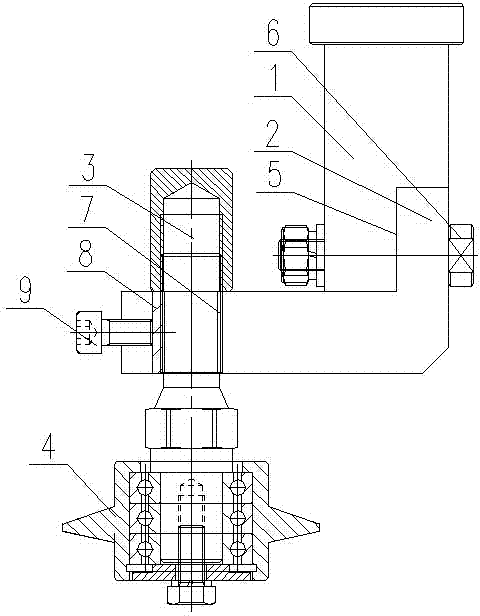

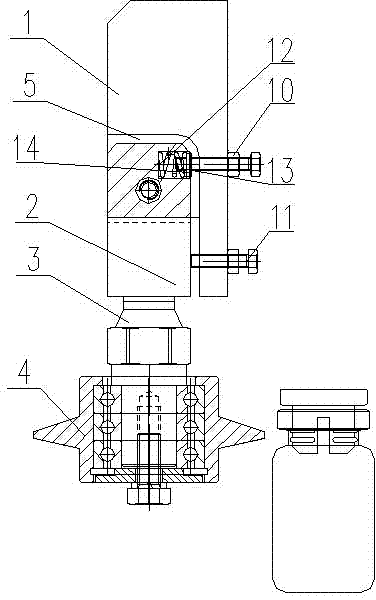

[0011] Such as figure 1 , 2 As shown, the present invention comprises a rolling knife arm 1, an adjusting lever 2, a rolling knife shaft 3 and a rolling knife 4, the bottom of the rolling knife arm 1 is provided with a groove 5, the adjusting lever 2 is L-shaped, and the vertical section of the adjusting lever 2 passes through The pin shaft 6 is rotatably connected in the groove 5 of the lower part of the rolling knife arm 1, the rolling knife 4 is rotatably installed on one end of the rolling knife shaft 3, the horizontal section of the adjusting lever 2 is provided with a threaded hole 7, and the threaded hole 7 An arc-shaped tension block 8 is attached to the inner wall, and the rolling knife shaft 3 is threaded in the above-mentioned threaded hole 6 , and a tension screw 9 against the tension block 8 is threaded on the adjustment lever 2 .

[0012] The side wall of the adjusting lever 2 is provided with a groove 12, and a spring 13 is arranged in the groove, and two adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com