Mechanical and electrical equipment installation mechanism for lifting single-lock bucket basket type rotary substation

A technology of electromechanical equipment and installation mechanism, applied in the direction of lifting devices, etc., can solve the problems of unusable large-scale operation tools, hidden dangers of personnel working safety, and large power outage range, so as to reduce installation coordinators, eliminate hidden safety hazards, and reduce power outage time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

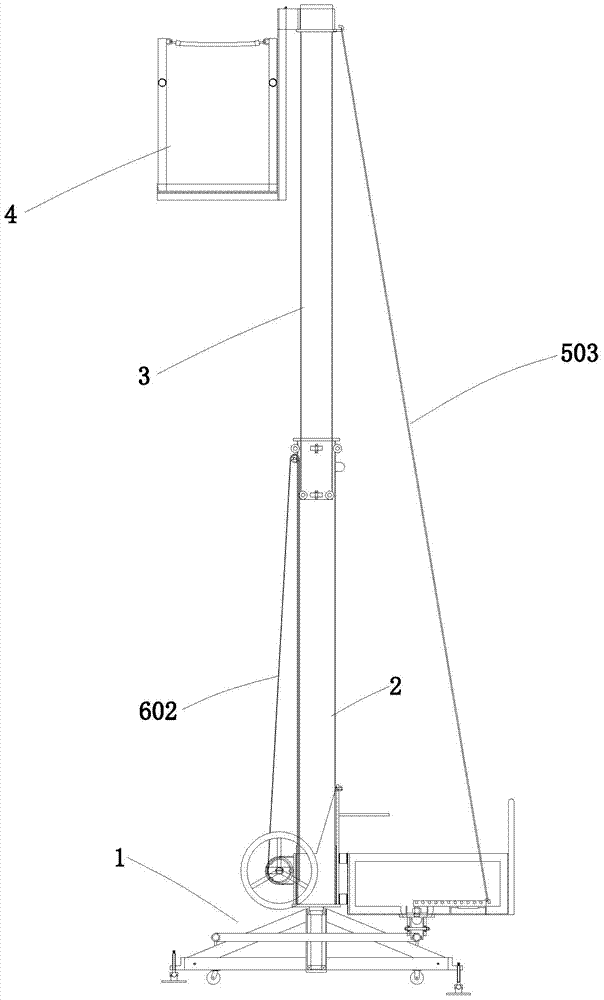

[0027] Embodiment: Referring to the accompanying drawings, the structural features of the electromechanical equipment installation mechanism of the lifting single-locking bucket-type rotating substation in this embodiment are as follows:

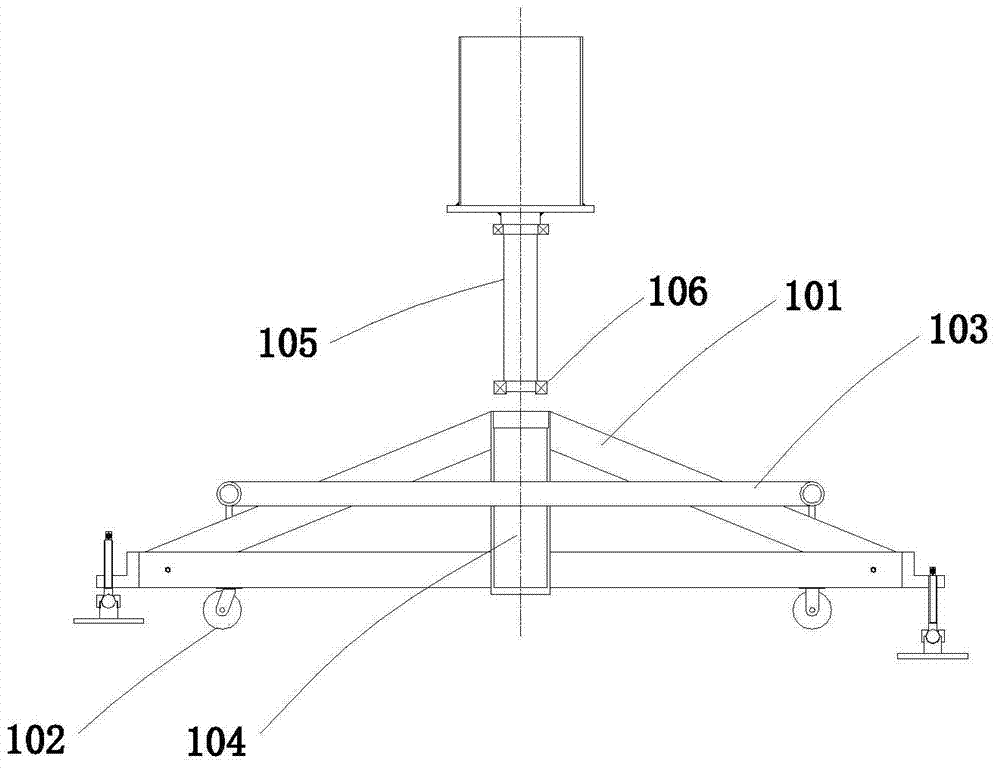

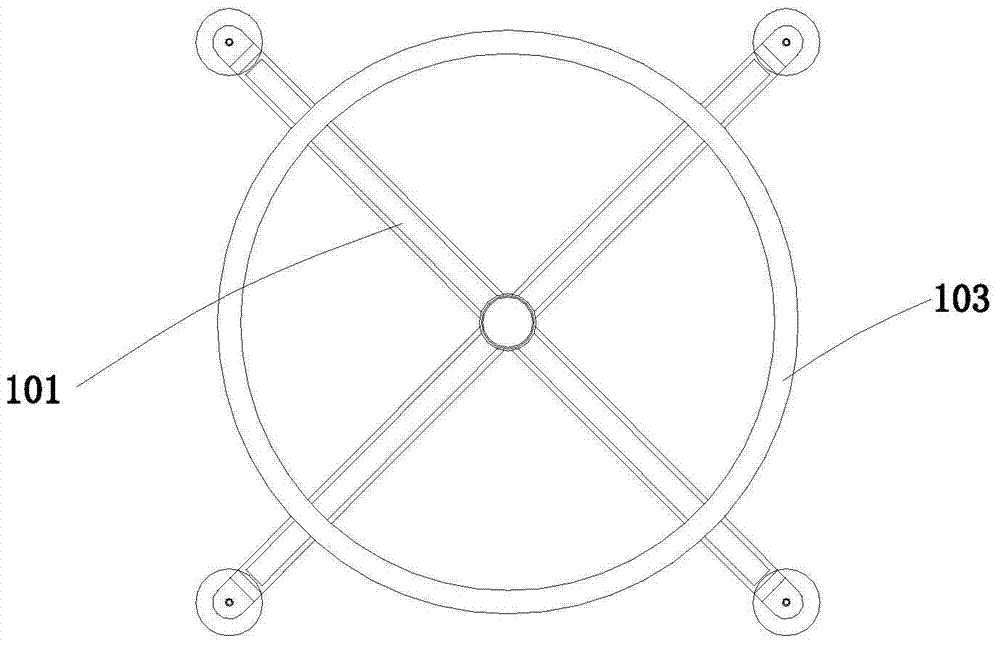

[0028] Set up the mechanism base 1, the base includes cross-shaped outriggers 101 and universal wheels 102 located at the bottom of the outriggers, a circular track 103 with the center of the base as the center is fixed on the outriggers, and the center of the base is fixedly connected with the outriggers The longitudinal sleeve 104.

[0029] In order to realize the rotation of the mechanism, a rotating column 105 inserted on the sleeve 104 is provided, and the lower half of the rotating column inserted into the sleeve is fixedly sleeved with a tapered roller bearing 106 matching the inner diameter of the sleeve. The half part is a square tube; set up a square tube-type column base section 2 inserted in the square tube of the rotating column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com