An automatic rotary net filling and stewing machine

An automatic, head-to-head machine technology, applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of hard damage to the substrate, low printing efficiency, and low speed of the printing machine, so as to prevent the formation of nodules and ensure The effect of printing quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

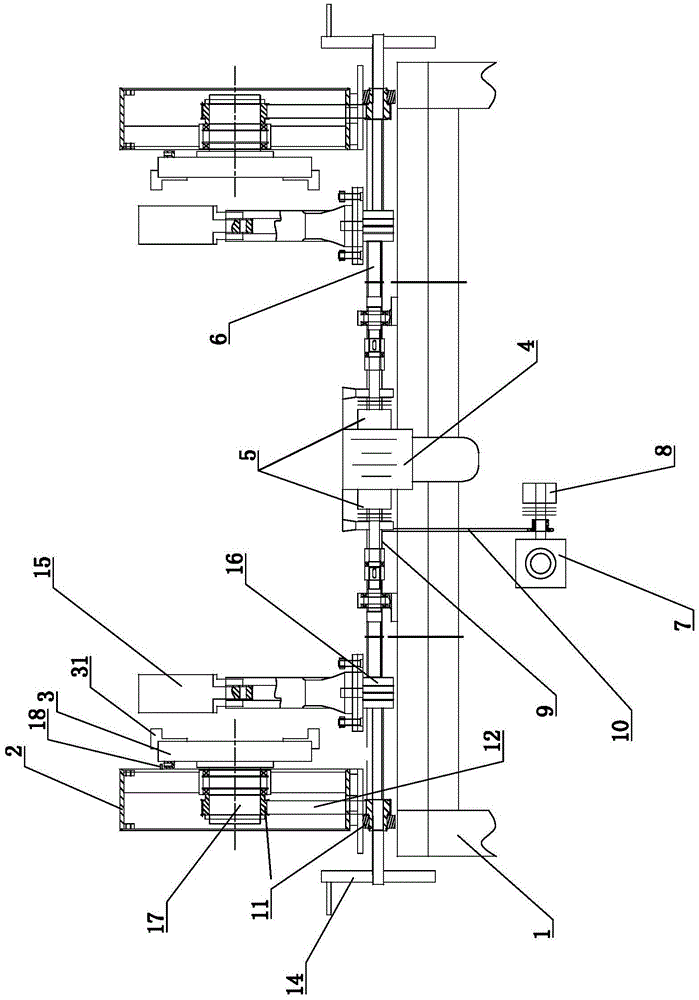

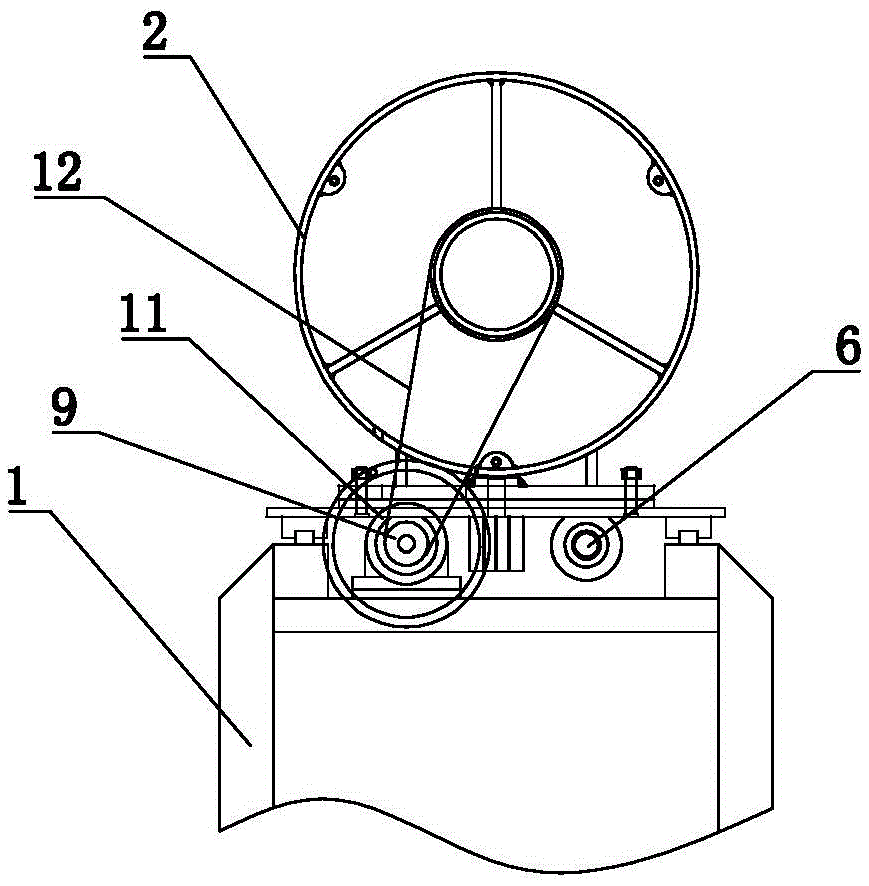

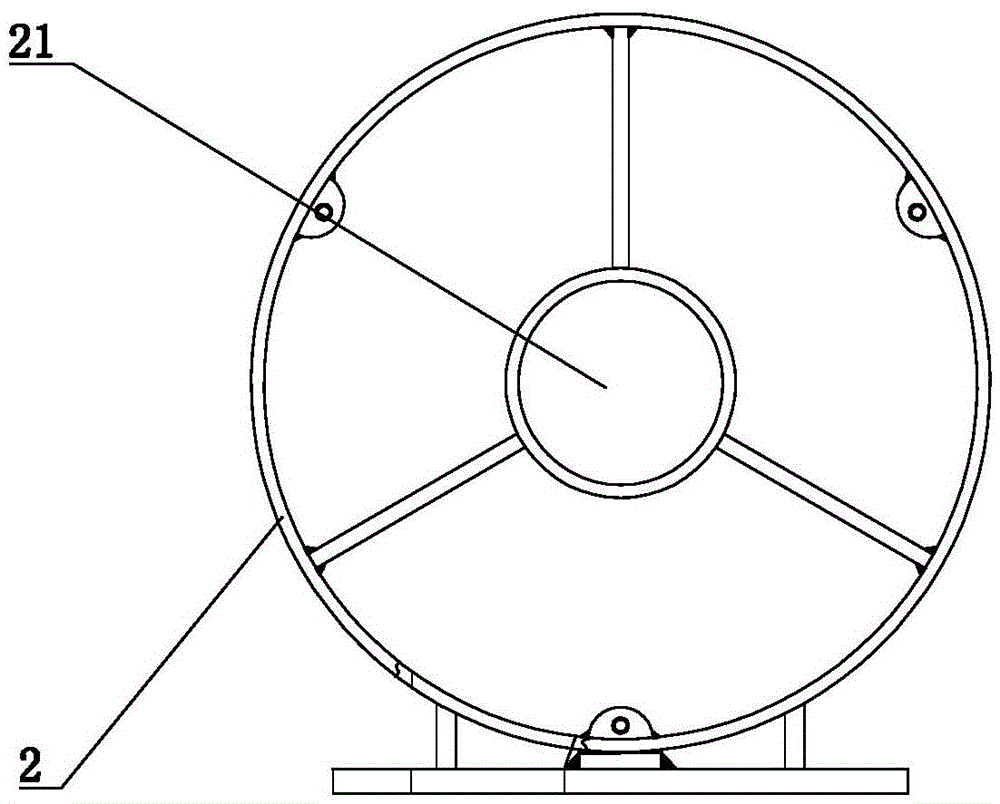

[0025] figure 1 is a structural schematic diagram of the present invention; figure 2 yes figure 1 Schematic diagram of the side view structure; image 3 yes figure 1 Schematic diagram of the structure of the chuck holder in ; Figure 4 yes figure 1 Schematic diagram of the chuck structure in .

[0026] refer to figure 1 , figure 2 , image 3 as well as Figure 4 , the automatic rotary net head stewing machine of the present invention comprises a frame 1, the two ends of the frame 1 are respectively provided with chuck frames 2, and the frame 1 between the two chuck frames 2 is provided with two holders. The rotary screen bracket 15 of the rotary screen, the two ends of the frame 1 are respectively fixedly provided with guide rails (not shown in the figure), and two chuck frames 2 are slidably matched with the two guide rails respectively; Transmission device and the first power device, the first transmission device cooperates with two chuck frames 2 respectively, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com