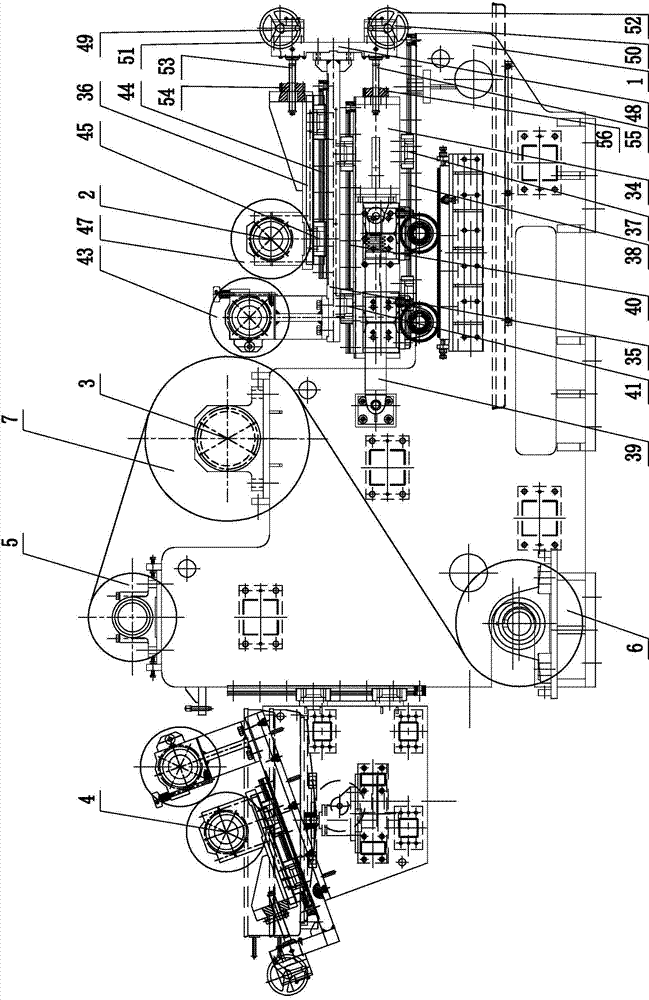

Main machine of bottom-coating roller coater

A technology of roller coater and main machine, which is applied in the direction of coating, liquid coating device on the surface, etc., which can solve the problems of lowering work efficiency, failure of coating on the dipping roller, difficulty in gap adjustment, etc., and achieves compact structure and guaranteed The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings.

[0023] Such as Figure 1 to Figure 11 As shown: the main machine of the primer roller coater includes a roller coater frame 1, a surface coating mechanism 2, a conveying roller mechanism 3, a backside coating mechanism 4, a first steering roller 5, a second steering roller 6, and a support roller 7 , Back coating frame 8, oil cylinder 9, first slider 10, first linear guide rail 11, back coating lifting mechanism 12, oil cylinder support 13, back coating bracket 14, back coating adjustment mechanism 15, back coating roller bracket 16. Back coating roller 17, second linear guide rail 18, second slider 19, back coating belt material roller support 20, back coating belt material roller 21, back coating coating disc 22, adjustment box 23, worm gear 24, worm screw 25 , the first coupling 26, the first shaft 27, the clutch 28, the second shaft 29, the second coupling 30, the first h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com