Method for capturing PM2.5 fine particles through water mist charged coagulation for electric precipitation

A PM2.5 and electrostatic precipitator technology, applied in the field of air pollution control, can solve the problems that electrostatic precipitator cannot capture, and it is difficult to meet the requirements of atmospheric particulate matter emission, so as to improve the difficulty of charging, promote condensation and agglomeration, and increase viscous force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

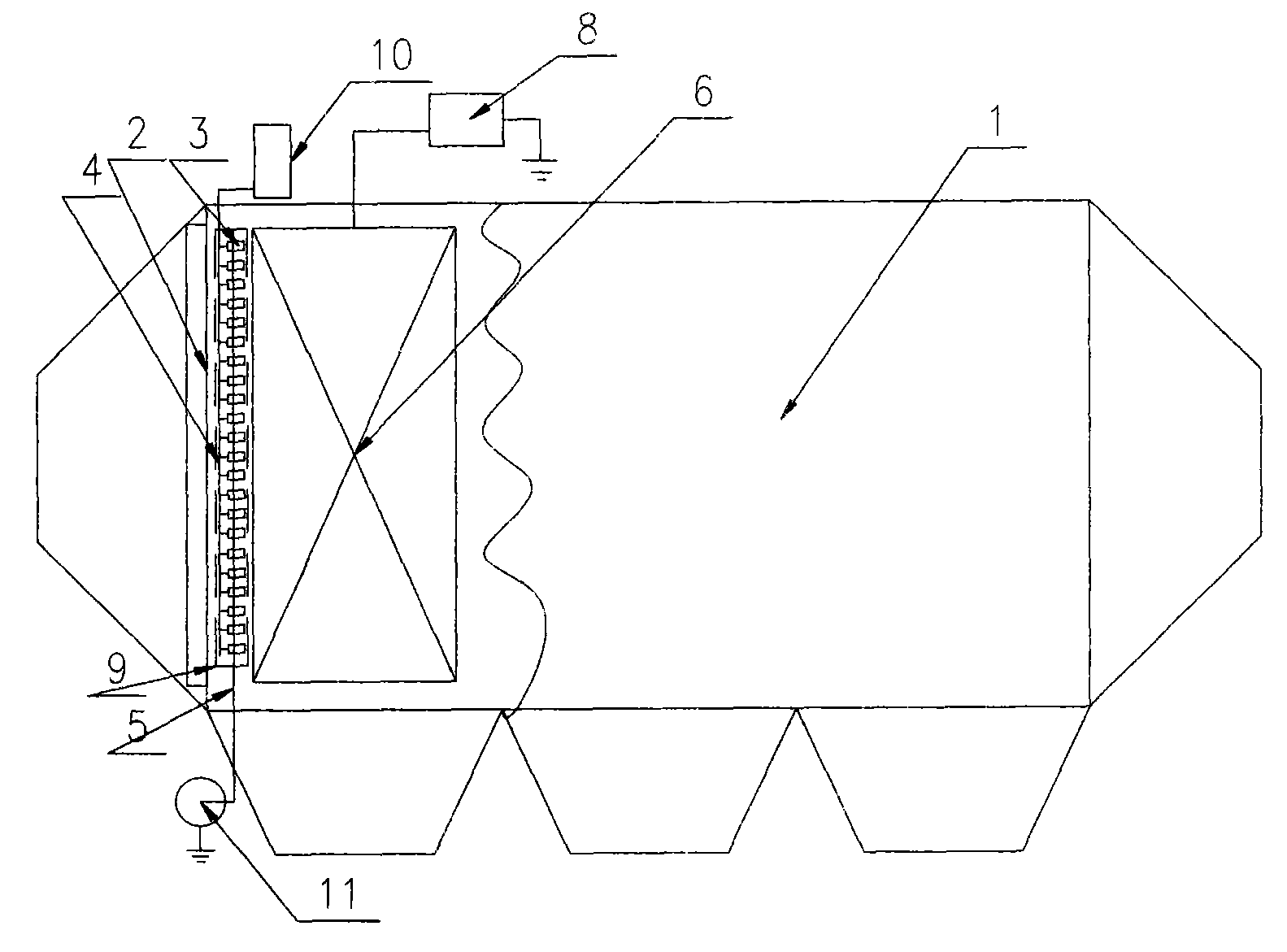

[0017] Example 1 as figure 1 As shown, the atomizing device 9 is composed of several dual-fluid nozzles 3, dual-fluid nozzle water supply pipelines 4, and dual-fluid nozzle air supply pipelines 5, and is installed between the air inlet air distribution plate 2 and the primary electric field 6 in the electrostatic precipitator 1. During this period, the liquid containing electrolyte and surfactant from the two-fluid nozzle water supply pipeline 4 and the air from the two-fluid nozzle air supply pipeline 5 form a water mist liquid and spray it into the primary electric field 6 under the action of the two-fluid nozzle 3. In the primary electric field 6, the corona is charged, and the charged liquid droplets collide with the particles entrained in the flue gas. On the one hand, the water mist can condition the flue gas and improve the working condition of the electrostatic precipitator. On the other hand, it contains electrolyte and The charged liquid of the surfactant collides wi...

Embodiment 2

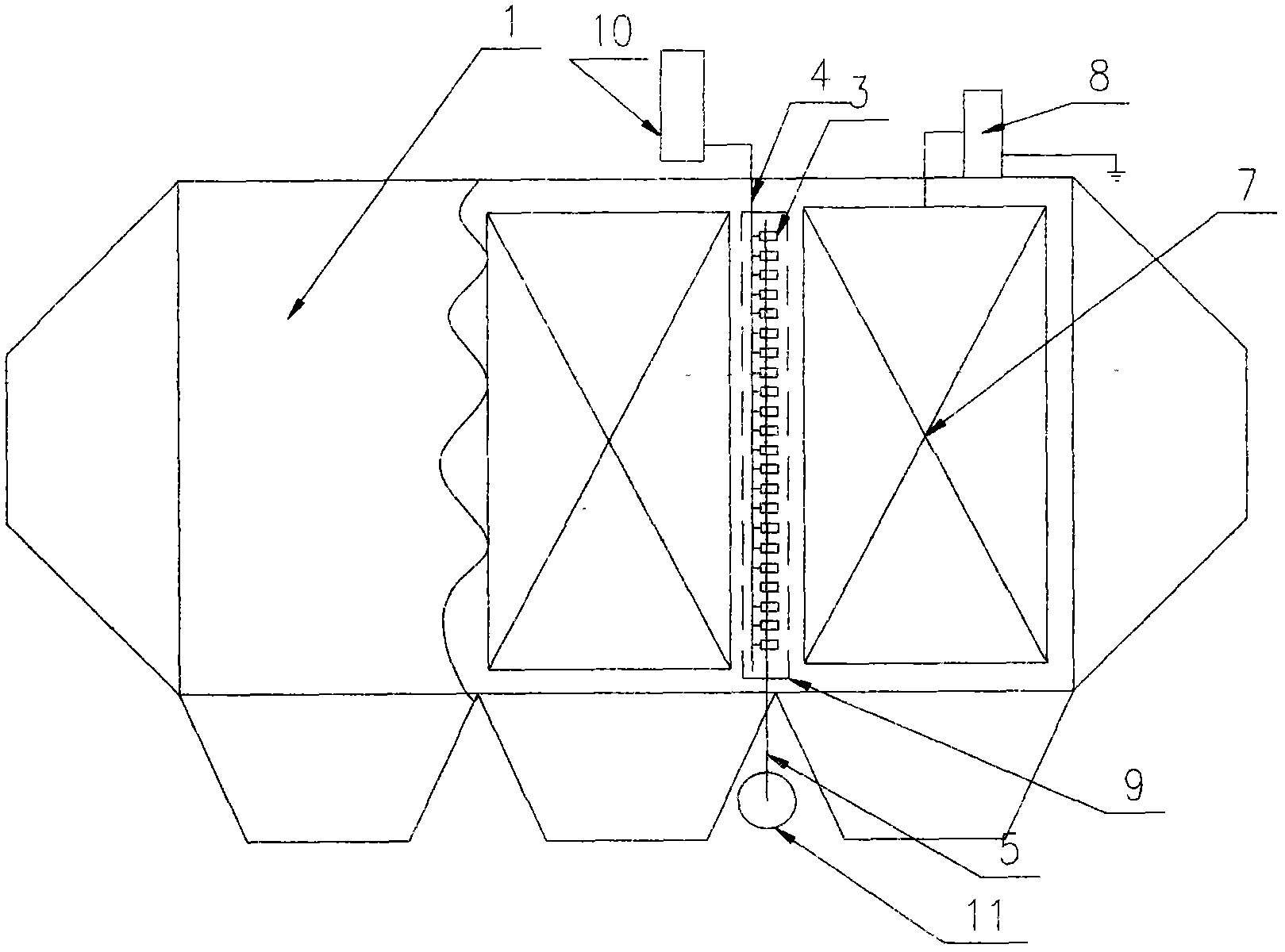

[0018] Example 2 as figure 2 As shown, the atomizing device 9 is composed of a dual-fluid nozzle 3, a dual-fluid nozzle water supply pipeline 4, and a dual-fluid nozzle air supply pipeline 5, and is installed between the final electric field 7 and the penultimate electric field in the electrostatic precipitator 1, The liquid containing electrolyte and surfactant from the two-fluid nozzle water supply pipeline 4 and the air from the two-fluid nozzle air supply pipeline 5 form a water mist liquid sprayed into the primary electric field 6 under the action of the two-fluid nozzle 3, and in the primary electric field 6. Corona charging, the charged liquid droplets collide with the particles entrained in the flue gas. On the one hand, the water mist can condition the flue gas and improve the working condition of the electrostatic precipitator. On the other hand, it contains electrolytes and surface activation The charged liquid of the agent collides with the particles in the flue g...

Embodiment 3

[0019] The difference between Embodiment 3 and Embodiment 2 is that the atomizing device 9 is installed between the second-to-last electric field and the third-to-last electric field. Others are the same and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com