An electronic cigarette vaporizer heating device

A technology of electronic vaporizer and heating device, which is applied in the fields of tobacco, smoker’s supplies, applications, etc. It can solve the problems of fiber rope reducing the fluid guiding performance, not getting mixed output, difficult to diffuse smoke, etc., and achieves convenient assembly of fluid guiding Sufficient supply of medium and smoke liquid to improve the taste of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

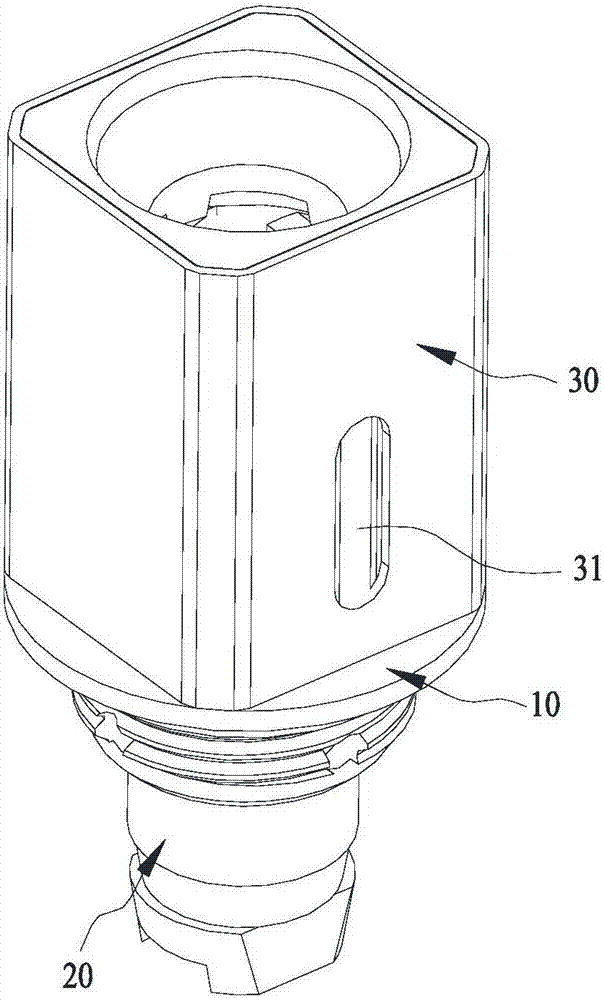

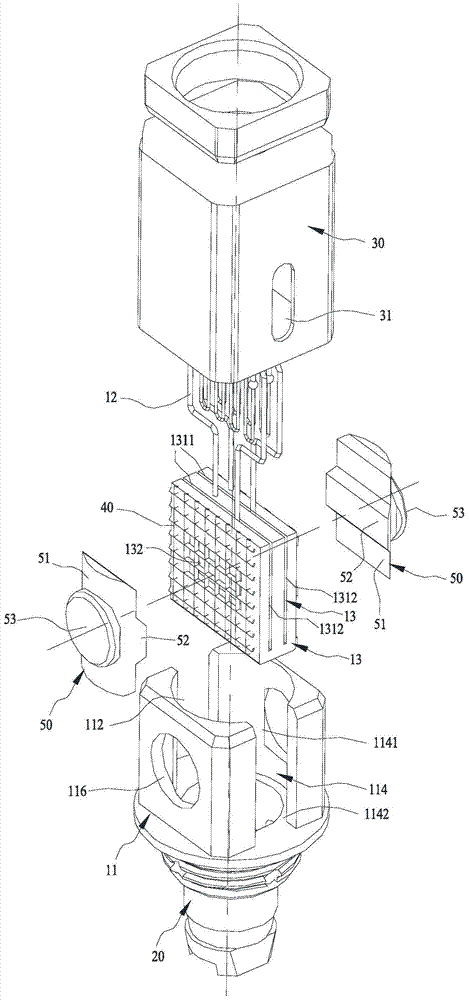

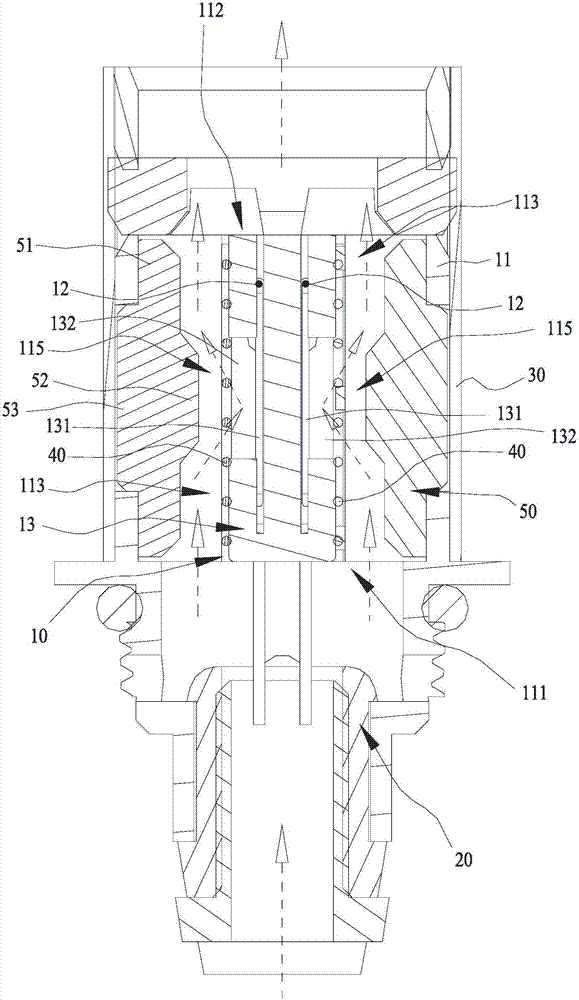

[0030] Such as Figure 1~3 The shown heating device of an electronic cigarette vaporizer includes a heating component 10 and a conductive component 20. The heating component 10 includes a fixing seat 11, a heating wire 12 and a liquid-conducting medium 13 for conducting smoke liquid. The fixing seat 11 is a medium The empty housing has an airflow inlet 111 and an airflow outlet 112 respectively located at opposite ends, and an airflow channel 113 for air flow is formed in the fixed seat 11 between the airflow inlet 111 and the airflow outlet 112, and the liquid guiding medium 13 is fixed on the fixed seat 11, the liquid guiding medium 13 is provided with an embedded groove 131, the heating wire 12 is embedded in the embedded groove 131 and is attached to the inner wall of the embedded groove 131, and at least one groove wall of the embedded groove 131 is provided with a hole that runs through the groove wall. The smoke port 132, the embedded groove 131 communicates with the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com