Lithium secondary battery comprising multilayered active material layer

A lithium secondary battery and active material technology, applied in the field of lithium secondary batteries, can solve problems such as lithium side reactions, and achieve the effects of improving initial efficiency, high power and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

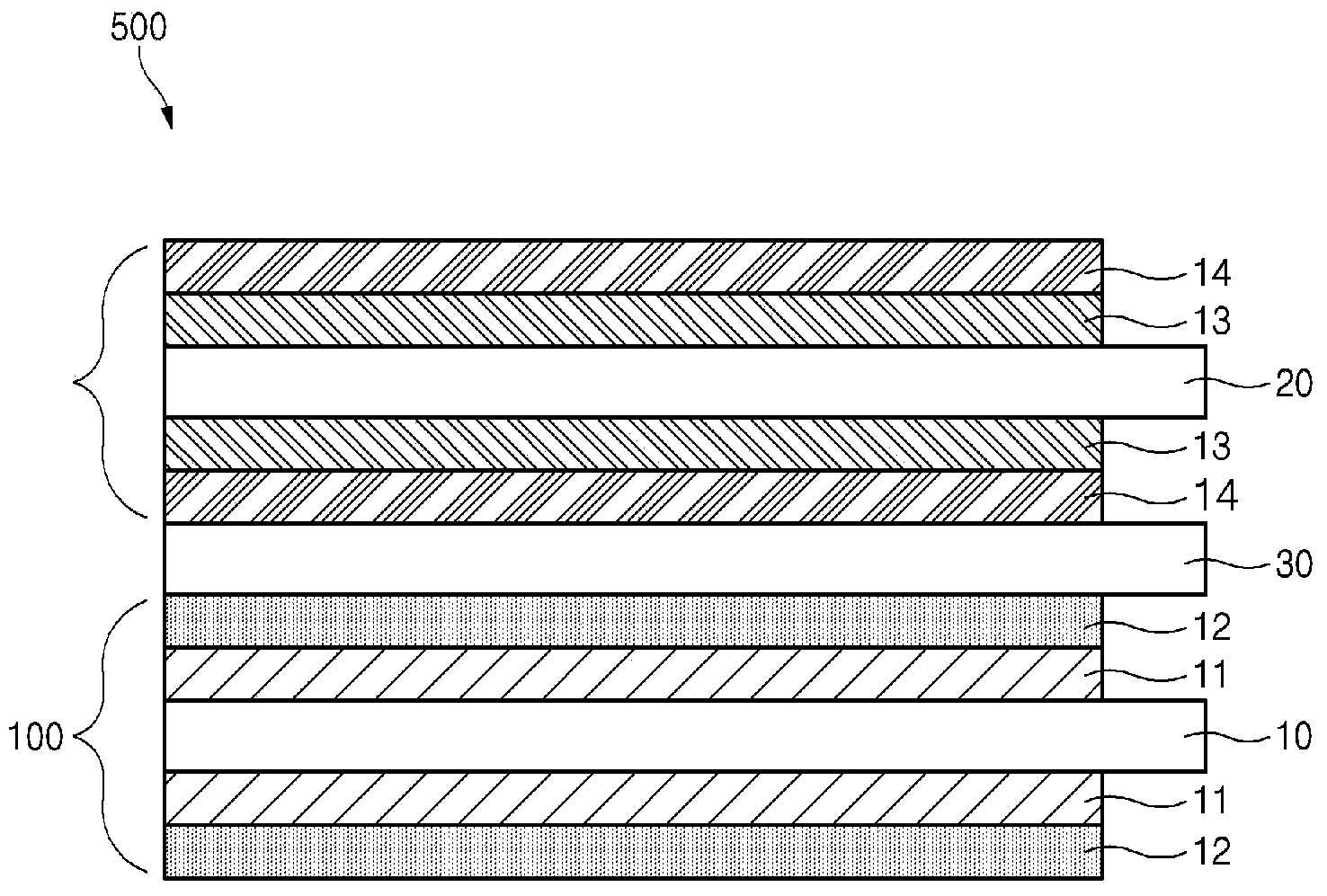

[0056] The preparation method of the positive electrode of the present invention comprises: on at least one side of the current collector, coating a slurry containing a lithium manganese oxide active material with a spinel structure and drying, thereby forming a first positive electrode active material layer; and A step of forming a second positive electrode active material layer by coating a slurry containing a layered lithium composite oxide active material on the surface of the first positive electrode active material layer and drying.

[0057] These slurries can be prepared by mixing an active material, a conductive agent, a binder, and the like in a predetermined solvent.

[0058]Usually, 1 to 20 weight percent of the above-mentioned conductive agent is added based on the entire weight of the mixture containing the positive electrode active material. As such a conductive agent, as long as it does not cause chemical changes in the battery and has conductivity, it is not pa...

Embodiment 1

[0079] Embodiment 1: the preparation of lithium secondary battery

[0080]

[0081] Mix 92% by weight of LiMn as the first positive electrode active material 2 o 4 , 4 weight percent of super-p as a conductive material and 4 weight percent of polyvinylidene fluoride as a binder, thereby preparing the first positive electrode active material slurry.

[0082] The above-mentioned first positive electrode active material slurry was die-coated on both sides of an aluminum (Al) thin film which is a positive electrode current collector with a thickness of about 20 μm, and dried to obtain a first positive electrode active material layer.

[0083] Under normal temperature conditions, the above-mentioned first positive electrode active material layer was dried for 20 minutes, and formed on the above-mentioned first positive electrode active material layer as the second positive electrode active material by nozzle spraying of the second positive electrode active material slurry The s...

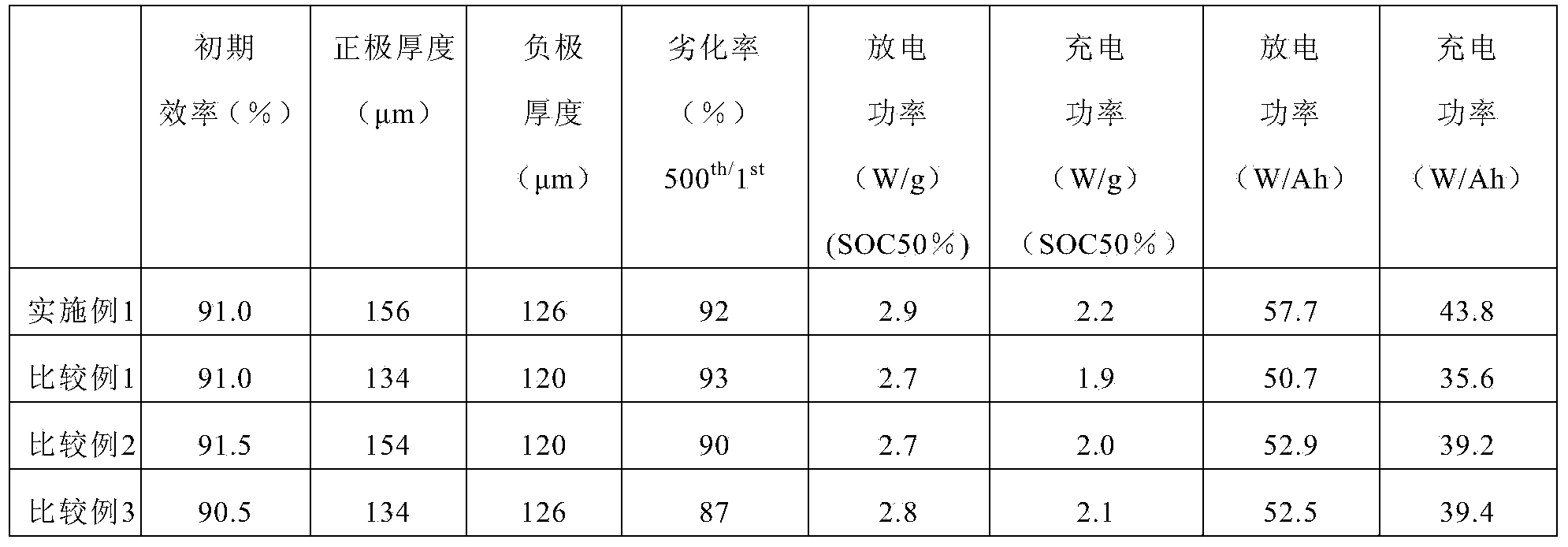

experiment example 1

[0108]

[0109] In order to understand the initial efficiency of the lithium secondary batteries prepared in the above-mentioned Example 1, Comparative Example 1, Comparative Example 2 and Comparative Example 3, under the conditions of constant current / constant voltage (CC / CV) at a temperature of 25° C. The lithium secondary batteries prepared in Example 1 and Comparative Examples 1 to 3 above were charged to 4.15V and 0.05C, and then discharged to 2.5V at 1C under constant current (CC) conditions to measure the initial efficiency. The above-mentioned initial efficiency is a value obtained by dividing the first discharge capacity by the first charge capacity, and the results obtained therefrom are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com