Anti-reversal device of vertical motor

A vertical motor and anti-reversal technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as inconvenient production, uncertain use of motors, complex structure, etc., and achieve reliable and stable operation, noise containment, and convenience The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

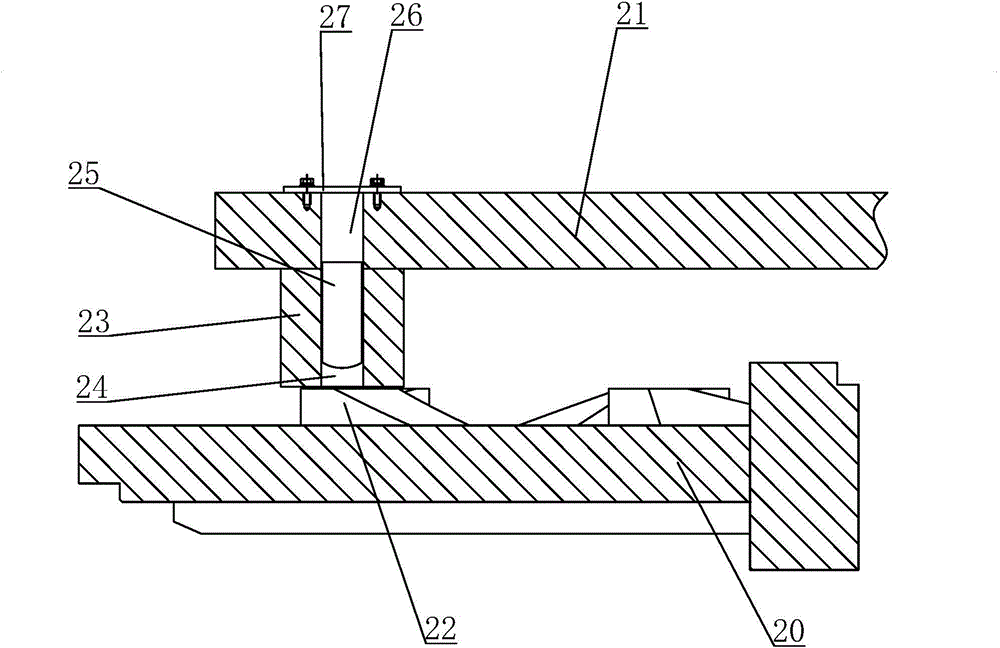

[0015] see figure 2 as shown, figure 2 It is a structural schematic diagram of the vertical motor anti-reverse device provided in Embodiment 1 of the present invention.

[0016] In this embodiment, a vertical motor anti-reverse device includes a brake disc 20 and a rotating disc 21, the rotating disc 20 is installed on the motor shaft and rotates with the motor rotor, the brake disc 21 is designed with the motor end cover Integrate as a stationary non-rotating part. And one side of the brake disc 21 is provided with several stop blocks 22 with a sliding surface, the rotating disc 21 is arranged above the brake disc 20, and the bottom surface of the rotating disc 21 corresponds to The stop block 22 is welded and fixed with several fixed blocks 23, and the several fixed blocks 23 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com