Portable line tightening device

A cable tightener, portable technology, applied in the field of cable tightening devices, can solve the problems of many people, heavy tightening tools, and breakage, and achieve the effect of improving the safety factor, simple and compact structure, and preventing the cable from falling loose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

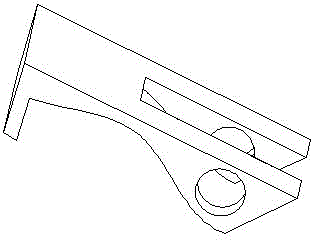

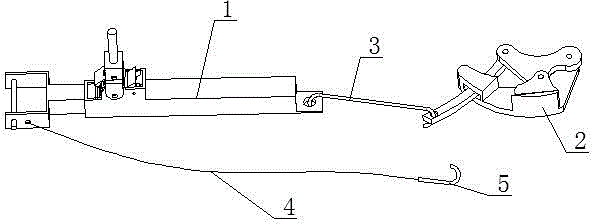

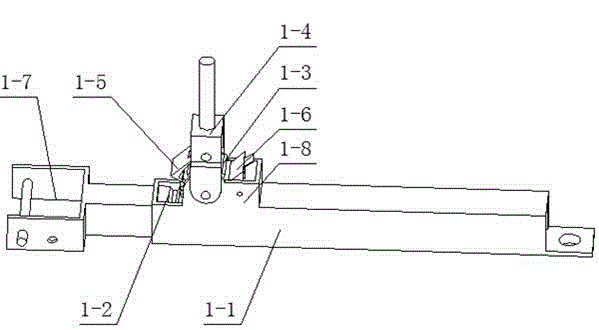

[0024] The portable wire tensioner includes a lifting device 1, the front end of the lifting device 1 is provided with a fixing ring 1-7 for fixing the wire tensioner, a hook b5 is connected to the side of the fixing ring 1-7, and a card is connected to the lower end of the lifting device 1 through a hook a3 Connector 2. During operation, the cable is clamped between the upper clamping sleeve 2-5 and the lower clamping sleeve 2-4 of the clamping device 2, and the handle 1-4 of the lifting device 1 is pulled repeatedly to realize the lifting of the cable. When the hoisting device 1 shrinks to the shortest point and still cannot meet the needs of tightening the thread, the hook b5 is hooked to the thread gripper 2, and the spare thread gripper 2 is installed to continue lifting. The invention has a simple and compact structure, is convenient to carry, and is reliable i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com