Reversing radar sensor and manufacturing method thereof

A reversing radar and sensor technology, which is applied in the direction of instruments, radio wave reflection/re-radiation, and re-radiation, can solve the problems of complex assembly of reversing radar sensors, difficulty in machine automation production, and unfavorable product consistency. Avoid easy water ingress, simplify and facilitate assembly, and combine tightly and firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

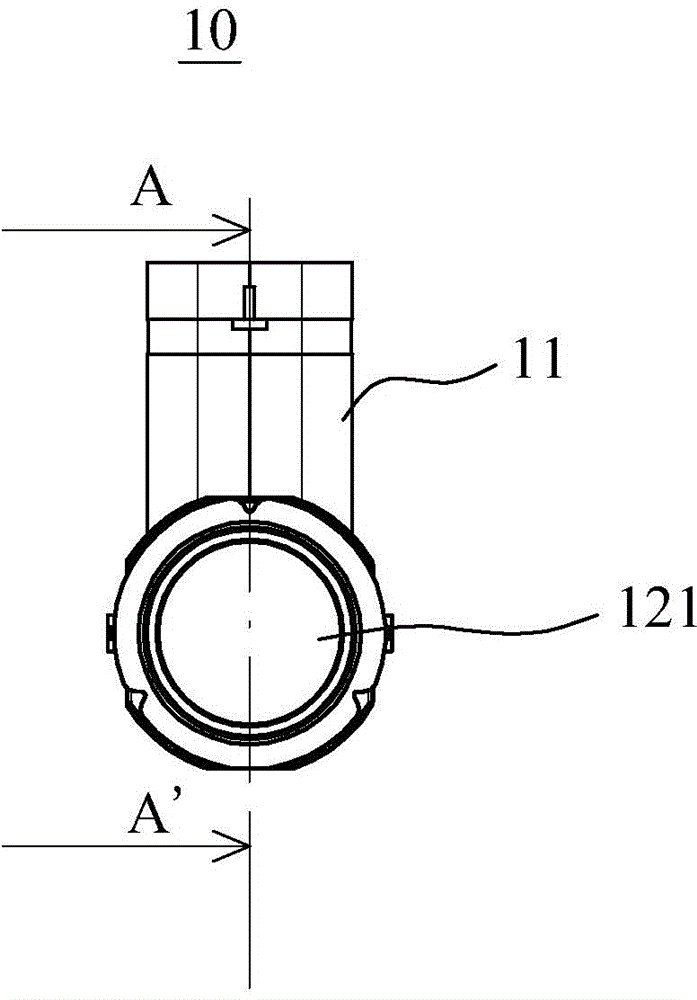

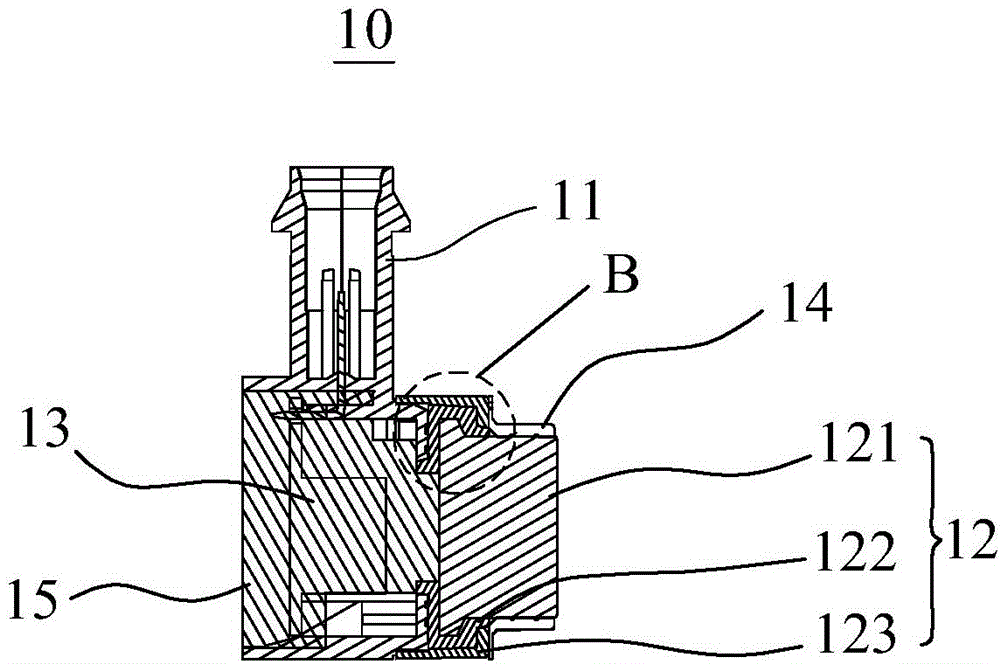

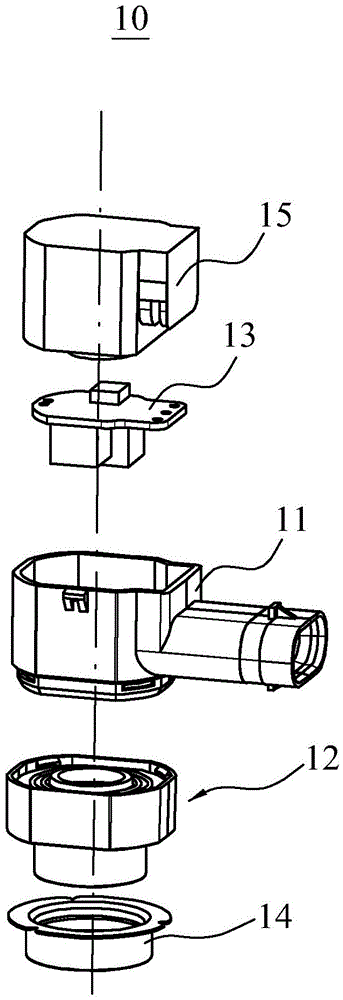

[0021] see Figure 1-3 , shows the reversing radar sensor 10 of the embodiment of the present invention, the sensor 10 includes a cavity 11, a probe assembly 12 installed in the cavity 11, the probe assembly 12 includes a probe core 121, an inner liner 122 and a front cover 123. The probe core 121 is located in the front cover 123, and the liner 122 is arranged between the probe core 121 and the front cover 123. The probe assembly 12 is a combination of the liner 122, the front cover 123 and the probe core 121 through injection molding and melting. structure.

[0022] Specifically, the cavity 11 is the housing of the sensor, and the structure adopts a manner suitable for installation and sensing. The probe assembly 12 is installed at an opening of the cavity 11 . The sensor 10 also includes a circuit board 13 electrically connected to the prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com