Crude oil quantitative sampling device

A quantitative sampling and crude oil technology, applied in the sampling device and other directions, can solve the problems of high failure rate, sampling error of measuring equipment, easy damage of sealing ring, etc., and achieve the effect of good working performance, reasonable structure and accurate sampling amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

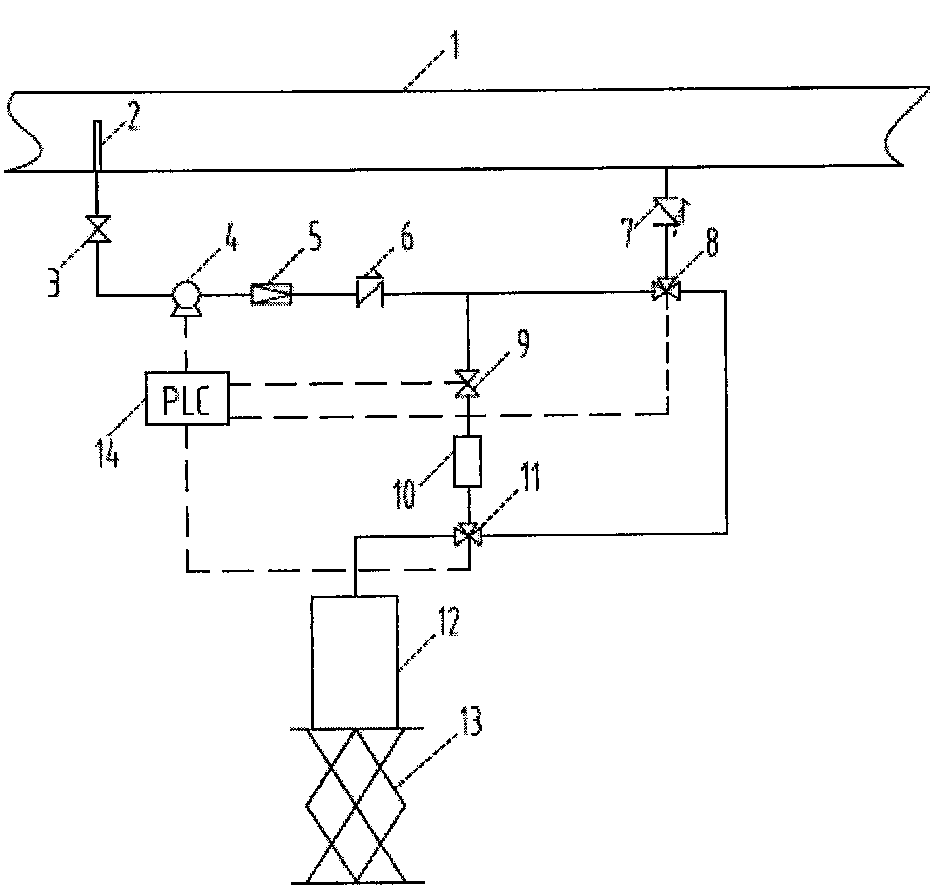

[0012] A crude oil quantitative sampling device, including a sampling probe 2 extending into a crude oil pipeline 1, the sampling probe is sequentially connected to a manual ball valve 3, a circulation pump 4, a filter 5, a first check valve 6, and a first pneumatic tee through a circulation pipeline Valve 8, the second check valve 7, the second check valve 7 communicates with the crude oil pipeline 1 through the circulation pipeline, and the circulation pipeline between the first check valve 6 and the first pneumatic three-way valve 8 is connected to the sampling pipeline; A pneumatic ball valve 9, a quantitative tank 10, a second pneumatic three-way valve 11 are arranged in sequence on the sampling pipeline, and finally a sample receiving bottle 12 is connected; the first pneumatic three-way valve 8 and the second pneumatic three-way valve 11 are connected by a pipeline, A lifting platform 13 is arranged below the sample receiving bottle.

[0013] The crude oil passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com