External-excitation multi-stage oscillation jet flow gas wave refrigerator

A gas wave refrigerator, oscillating jet technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reducing refrigeration efficiency, deteriorating the cycle process of gas wave tubes, reducing refrigeration efficiency, etc., to achieve distribution flow and time. Equalize, eliminate the effects of short exhaust time, reduced footprint and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

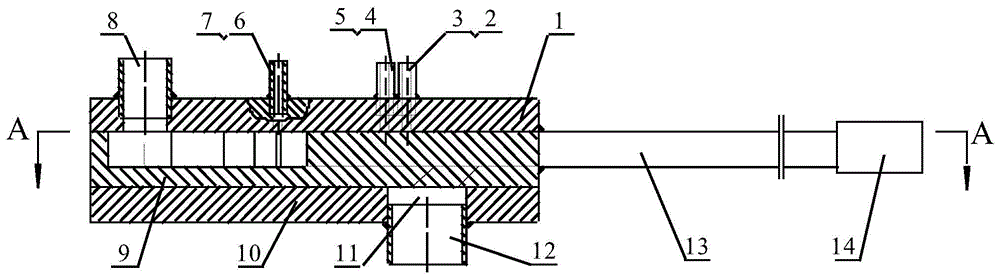

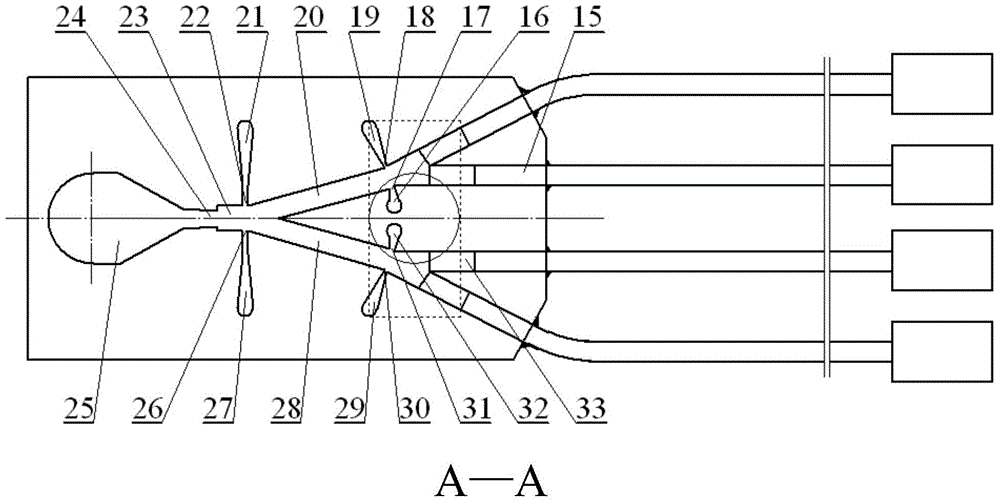

[0032] The externally excited multi-stage oscillating jet air wave refrigerator of the present invention comprises a body 9, an upper cover plate 1, a bottom plate 10, a pressure gas inlet pipe 8, a refrigerant gas outlet pipe 12, an even number of receiving pipes 13, and a wave breaking at the end of each receiving pipe. Cavity 14, and many pairs of excitation flow inlet pipes 2, 3, 4, 5, 6, 7 and other parts.

[0033]On the upper surface of the body 9, which is symmetrical to the central axis, a pressure gas inlet buffer cavity 25, a nozzle flow channel 24, and a main jet flow channel 24 are arranged and processed in sequence, with a certain depth, the maximum value being the full thickness of the body, and the pressure gas inlet buffer chamber 25 communicated with the pressure gas inlet pipe 8. The flow channel 23, and the first-stage oscillation left branch flow channel 20 and the first-stage oscillation right branch flow channel 28 are symmetrically arranged. The refriger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com